Sulfate tracer agent for tertiary oil recovery and preparation method of sulfate tracer agent

A tracer, sulfate technology, used in construction and other directions, can solve problems such as large errors, human and environmental safety hazards, poor adaptability and selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

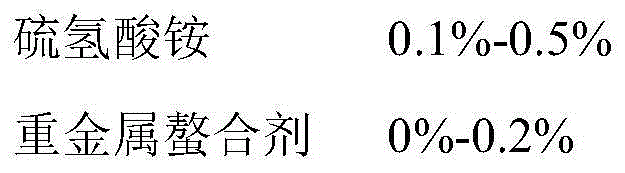

[0015] Embodiment one: the composition of described tertiary oil recovery sulfate tracer, by mass percentage, formula is:

[0016]

[0017] Under the stirring condition of 800r / min, after mixing the ammonium sulfide and the heavy metal chelating agent with water according to the above ratio, add a wetting agent and continue to stir, and finally add a pH regulator to adjust the pH to 9, and after 0.5 hours of natural sedimentation , to obtain the working solution of the tracer.

Embodiment 2

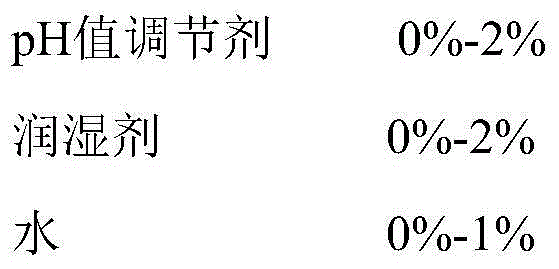

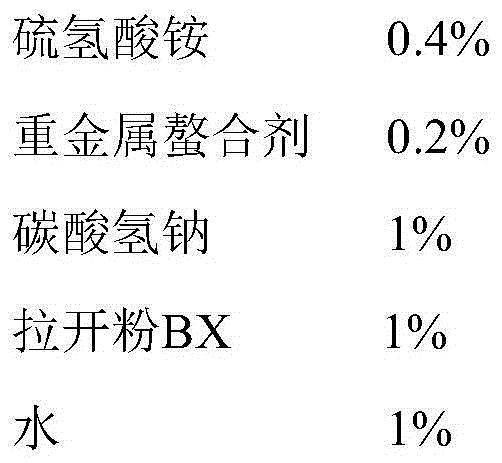

[0018] Embodiment two: the composition of described tertiary oil recovery sulfate tracer, by mass percentage, formula is:

[0019]

[0020]

[0021] Under the stirring condition of 1000r / min, mix the ammonium sulfide and the heavy metal chelating agent with water according to the above ratio, add a wetting agent and continue to stir, and finally add a pH regulator to adjust the pH to 9, and after 1 hour of natural sedimentation , to obtain the working solution of the tracer.

[0022] Compared with the first embodiment, the second embodiment has better adaptability and selectivity.

Embodiment 3

[0023] Embodiment three: the composition of described tertiary oil recovery sulfate tracer, by mass percentage, formula is:

[0024]

[0025] Under the stirring condition of 8000r / min, after mixing the ammonium sulfide and the heavy metal chelating agent with water according to the above ratio, add a wetting agent and continue to stir, and finally add a pH regulator to adjust the pH to 9, and after natural sedimentation for 1 hour , to obtain the working solution of the tracer.

[0026] Compared with the second embodiment, the third embodiment has a higher test resolution.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com