Ball-throwing type controllable wall scraper and method for cleaning inner wall of sleeve

A wall scraper and ball-throwing technology, which is applied in the direction of cleaning equipment, earthwork drilling, wellbore/well parts, etc., can solve the problems of complex drill sticking and wall scraper failure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

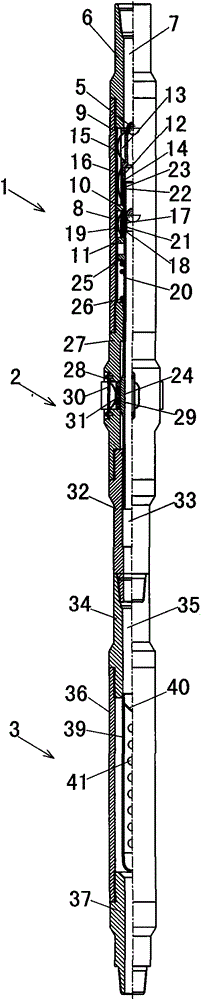

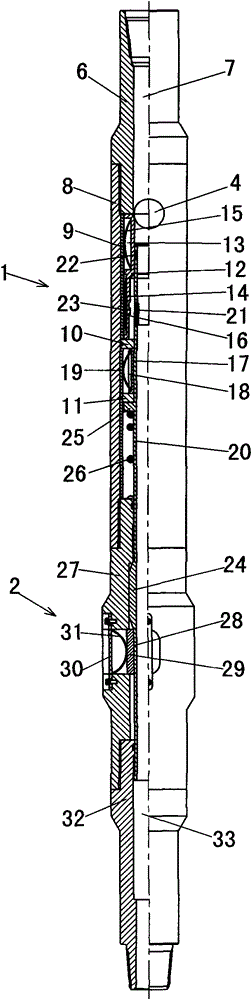

[0028] Such as Figure 1 to Figure 4 As shown, the wall scraper of the present invention includes a control system 1 , a cutter system 2 , a recovery system 3 , and at least one first steel ball 4 and at least one second steel ball 5 for controlling the operation of the control system 1 from top to bottom.

[0029]The control system 1 includes a first joint 6, the center of the first joint 6 is provided with a first through hole 7, the upper end of the first joint 6 is connected to the drill pipe 42, the lower end of the first joint 6 is connected to the piston sleeve 8, and the piston sleeve 8 The lower end is fixed on the cutter system 2. The inner cavity of the piston sleeve 8 is sleeved with a first positioning sleeve 9, the first positioning sleeve 9 is located between the first joint 6 and the tool system 2, and the inner cavity wall of the first positioning sleeve 9 is distributed up and down. There are first dead point positioning block 10 and second dead point positi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com