Construction method for renovating horizontal deformation hazards of terminal spines of ballastless tracks

A technology of horizontal deformation and ballastless track, which is applied in the direction of track, track maintenance, track superstructure, etc., can solve the problems of hard to find disease, long time-consuming, high cost, etc., and achieve the effect of improving utilization rate, less possibility and ensuring safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with accompanying drawing of description and specific embodiment:

[0027] The invention provides a construction method for treating the horizontal deformation of ballastless track end thorns, comprising the following steps:

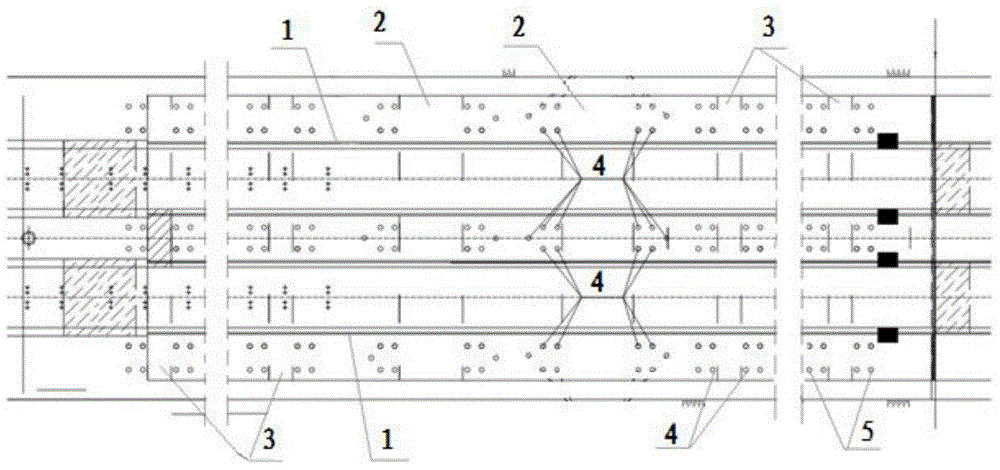

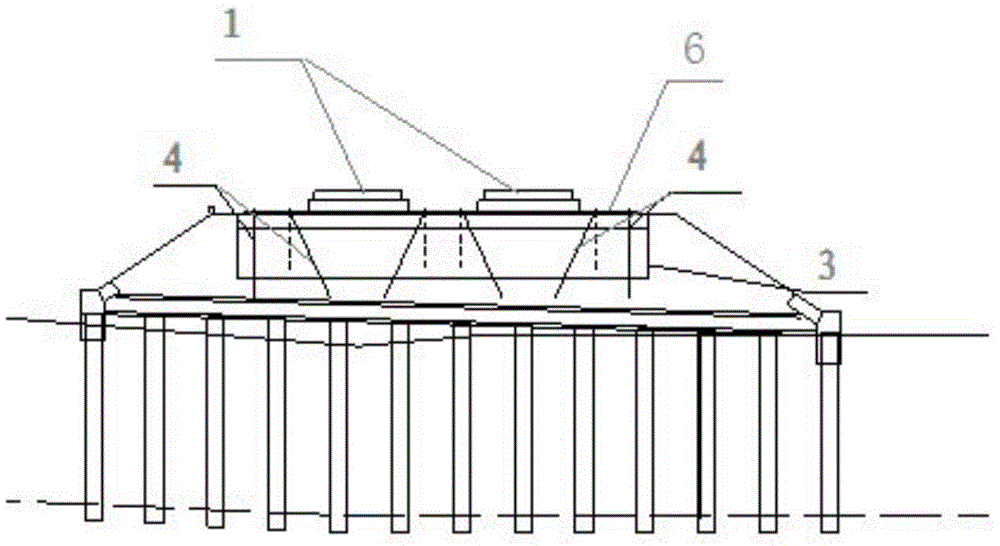

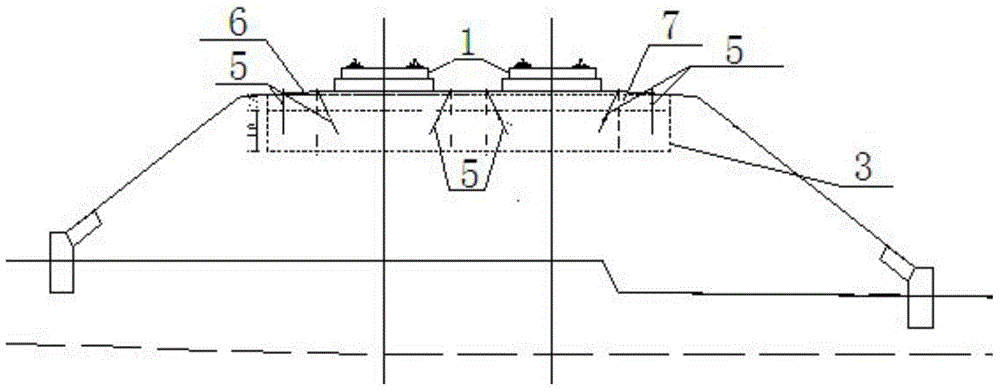

[0028] A. Ballastless track end thorn structure includes two track 1, base plate, friction plate 7, small end thorn 3 and big end thorn 2. Use red paint to draw marked points as observation points every 10 meters, and arrange deformation monitoring instruments at the same time. The deformation monitoring instruments monitor the distance between the two observation points in real time to calculate the track deformation status;

[0029] B. Drill grouting holes 8 on the subgrade surfaces on both sides of the small end thorns 3 and the large end thorns 2 outside the two rails 1 . Among them, there are three rows of grouting holes distributed on the subgrade surface on both sides of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com