Salt-free low-alkali dyeing process for cellulosic fibers

A cellulose fiber and process technology, applied in the field of textile dyeing, can solve problems such as inability to apply to large-scale production, high chromaticity of dyeing residue, difficult treatment of waste water, etc., and achieves high success rate, good cationization effect, and reduced dye consumption. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

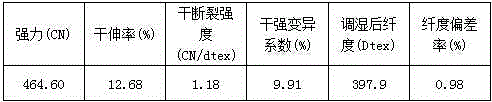

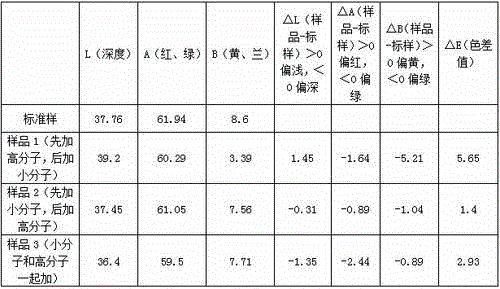

Embodiment 1

[0080] Cellulose fiber dyeing process:

[0081] A salt-free and low-alkali dyeing process for cellulose fibers, comprising the following process steps:

[0082] A. Cellulose fiber modification treatment

[0083] Put the cellulose fiber into the container, add water to the container, and then modify the cellulose fiber with two kinds of quaternary ammonium salt cationic modifiers, Modifier A and Modifier B, and obtain Modified cellulose fiber; the modifier A is a small-molecular quaternary ammonium salt cationic modifier, and the modifier B is a high-molecular quaternary ammonium salt cationic modifier;

[0084] B. Washing treatment

[0085] Washing the modified cellulose fibers obtained through the modification treatment in step A;

[0086] C. Dyeing

[0087] Putting the modified cellulose fibers washed with water in step B into a dyeing container, adding a dye solution for dyeing, then raising the temperature, continuing to dye for a period of time, and finishing dyeing t...

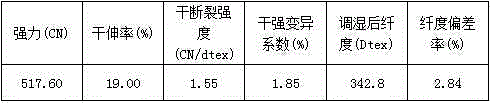

Embodiment 2

[0092] Cellulose fiber dyeing process:

[0093] A salt-free and low-alkali dyeing process for cellulose fibers, comprising the following process steps:

[0094] A. Cellulose fiber modification treatment

[0095] Put the cellulose fiber into the container, add water to the container, and then use two kinds of quaternary ammonium salt cationic modifiers, modifier A and modifier B, to modify the cellulose fiber, and obtain Modified cellulose fiber; the modifier A is a small molecule quaternary ammonium salt cationic modifier, and the modifier B is a high molecular weight quaternary ammonium salt cationic modifier;

[0096] B. Washing treatment

[0097] Washing the modified cellulose fibers obtained through the modification treatment in step A;

[0098] C. Dyeing

[0099] Putting the modified cellulose fibers washed with water in step B into a dyeing container, adding a dye solution for dyeing, then raising the temperature, continuing to dye for a period of time, and finishing...

Embodiment 3

[0105] Cellulose fiber dyeing process:

[0106] A salt-free and low-alkali dyeing process for cellulose fibers, comprising the following process steps:

[0107] A. Cellulose fiber modification treatment

[0108] Put the cellulose fiber into the container, add water to the container, and then use two kinds of quaternary ammonium salt cationic modifiers, modifier A and modifier B, to modify the cellulose fiber, and obtain Modified cellulose fiber; the modifier A is a small molecule quaternary ammonium salt cationic modifier, and the modifier B is a high molecular weight quaternary ammonium salt cationic modifier;

[0109] B. Washing treatment

[0110] Washing the modified cellulose fibers obtained through the modification treatment in step A;

[0111] C. Dyeing

[0112] Putting the modified cellulose fibers washed with water in step B into a dyeing container, adding a dye solution for dyeing, then raising the temperature, continuing to dye for a period of time, and finishing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com