Processing method of multifunctional double-side bicolor knitted fabric

A technology for knitted fabrics and processing methods, which is applied in the treatment, knitting, dyeing and other directions of textile materials to achieve the effects of good dye depth, good light fastness and fade fastness, and reduced sewage discharge.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

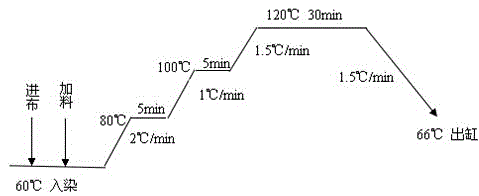

Image

Examples

specific Embodiment 1

[0059] A processing method for a multi-functional double-sided two-color knitted fabric, comprising the following steps:

[0060] Gray cloth → pre-treatment → dyeing → dehydration → cutting width → shaping → inspection → packaging;

[0061] The weaving equipment for the gray cloth is knitting double-sided cylindrical machine weaving, the front is 150D / 72F cationic modified DTY polyester yarn, the back is 75D / 72F nano-silver antibacterial, moisture-absorbing and sweat-wicking composite polyester yarn, and the cross-section of the fiber is a cross-shaped structure , product specifications: weight 150G / M 2 , door width 152CM.

[0062] In the pretreatment step, the specific technological process is as follows:

[0063] Cloth feeding → heating up to 60°C → adding degreasing agent and emulsifier successively → heating up to 90°C, processing for 20 minutes → cooling down to 70°C / min → washing cold water; specifically: put the cloth into the dye vat at normal temperature, and then ...

specific Embodiment 2

[0091] A processing method for a multi-functional double-sided two-color knitted fabric, comprising the following steps:

[0092] Gray cloth → pre-treatment → dyeing → dehydration → cutting width → shaping → inspection → packaging;

[0093] The weaving equipment for the gray cloth is knitting double-sided cylindrical machine weaving, the front is 150D / 72F cationic modified DTY polyester yarn, the back is 75D / 72F nano-silver antibacterial, moisture-absorbing and sweat-wicking composite polyester yarn, and the cross-section of the fiber is a cross-shaped structure , product specifications: weight 170G / M 2 , door width 154CM.

[0094] In the pretreatment step, the specific technological process is as follows:

[0095] Cloth feeding → heating up to 60°C → adding degreasing agent and emulsifier successively → heating up to 90°C, processing for 20 minutes → cooling down to 70°C / min → washing cold water; specifically: put the cloth into the dye vat at normal temperature, and then ...

specific Embodiment 3

[0123] A processing method for a multi-functional double-sided two-color knitted fabric, comprising the following steps:

[0124] Gray cloth → pre-treatment → dyeing → dehydration → cutting width → shaping → inspection → packaging;

[0125] The weaving equipment for the gray cloth is knitting double-sided cylindrical machine weaving, the front is 150D / 72F cationic modified DTY polyester yarn, the back is 75D / 72F nano-silver antibacterial, moisture-absorbing and sweat-wicking composite polyester yarn, and the cross-section of the fiber is a cross-shaped structure , product specifications: weight 160G / M 2 , door width 153CM.

[0126] In the pretreatment step, the specific technological process is as follows:

[0127] Cloth feeding → heating up to 60°C → adding degreasing agent and emulsifier successively → heating up to 90°C, processing for 20 minutes → cooling down to 70°C / min → washing cold water; specifically: put the cloth into the dye vat at normal temperature, and then ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com