Preparation method of neodymium-doped lead dioxide electrode

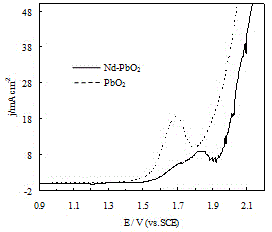

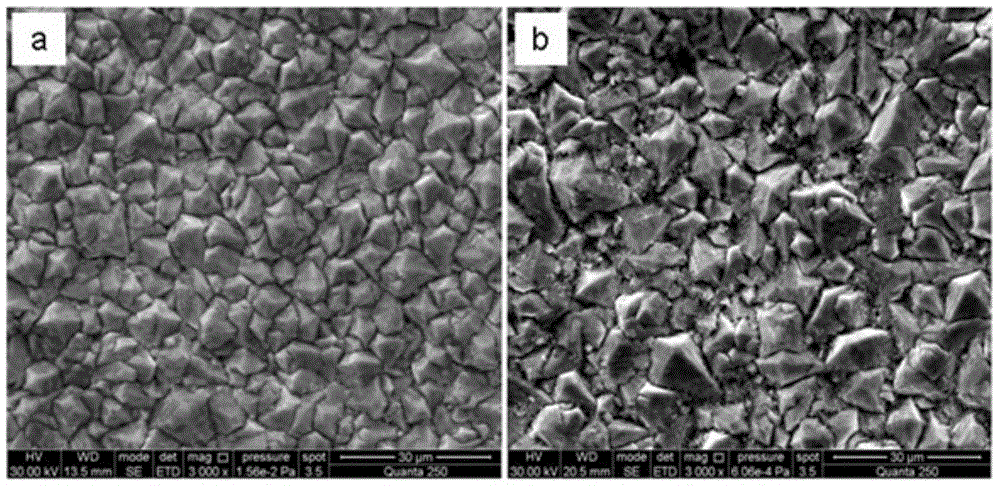

A technology doped with lead dioxide and neodymium, applied in chemical instruments and methods, electrolytic coatings, liquid chemical plating, etc., can solve the problems of poor stability of the active layer, short service life, poor catalytic performance, etc., and achieve OH capacity Strong, low operating cost, strong degradation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

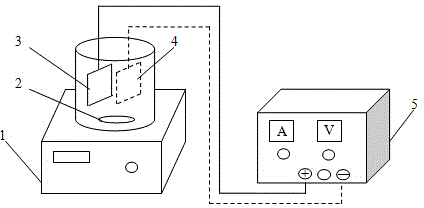

[0034] A method for preparing a neodymium-doped lead dioxide electrode. The neodymium-doped lead dioxide electrode uses titanium as a base, and the titanium base is a titanium sheet. After the titanium substrate is pretreated by grinding and etching, its surface is sequentially plated with a tin-antimony intermediate layer and a neodymium-containing oxide β -PbO 2 Crystal active layer; the preparation method includes sandblasting and polishing the surface of the titanium substrate, oxalic acid etching pretreatment, the surface of the substrate after the pretreatment is prepared by brushing thermal decomposition method to prepare the tin antimony oxide intermediate layer, and then in the prepared Electrodeposition is used in the electroplating solution to coat the surface of the intermediate layer with neodymium oxide β -PbO 2 Crystal active layer, thereby preparing the neodymium-doped lead dioxide electrode.

[0035] The method includes the following specific steps:

[0036] (1) Pr...

specific Embodiment 2

[0042] A method for preparing a neodymium-doped lead dioxide electrode. The neodymium-doped lead dioxide electrode uses titanium as a base, and the titanium base is a titanium tube. After the titanium substrate is pretreated by grinding and etching, its surface is sequentially plated with a tin-antimony intermediate layer and a neodymium-containing oxide β -PbO 2 Crystal active layer; the preparation method includes sandblasting and polishing the surface of the titanium substrate, oxalic acid etching pretreatment, the surface of the substrate after the pretreatment is prepared by brushing thermal decomposition method to prepare the tin antimony oxide intermediate layer, and then in the prepared Electrodeposition is used in the electroplating solution to coat the surface of the intermediate layer with neodymium oxide β -PbO 2 Crystal active layer, thereby preparing the neodymium-doped lead dioxide electrode.

[0043] The method includes the following specific steps:

[0044] (1) Pre...

specific Embodiment 3

[0050] A method for preparing a neodymium-doped lead dioxide electrode. The neodymium-doped lead dioxide electrode uses titanium as a base, and the titanium base is a titanium mesh. After the titanium substrate is pretreated by grinding and etching, its surface is sequentially plated with a tin-antimony intermediate layer and a neodymium-containing oxide β -PbO 2 Crystal active layer; the preparation method includes sandblasting and polishing the surface of the titanium substrate, oxalic acid etching pretreatment, the surface of the substrate after the pretreatment is prepared by brushing thermal decomposition method to prepare the tin antimony oxide intermediate layer, and then in the prepared Electrodeposition is used in the electroplating solution to coat the surface of the intermediate layer with neodymium oxide β -PbO 2 Crystal active layer, thereby preparing the neodymium-doped lead dioxide electrode.

[0051] The method includes the following specific steps:

[0052] (1) Pre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electric potential / voltage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com