A kind of composite polyether and the polyurethane sandwich panel made from it

A technology of polyurethane sandwich panel and combining polyether, which is applied in the direction of synthetic resin layered products, lamination and layered products, etc., can solve the problem of not uniform density distribution, high overall density of polyurethane sandwich panels, and insufficient production rate Advanced problems, to achieve the effect of improving market competitiveness, good dimensional stability, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~5 and comparative example 1

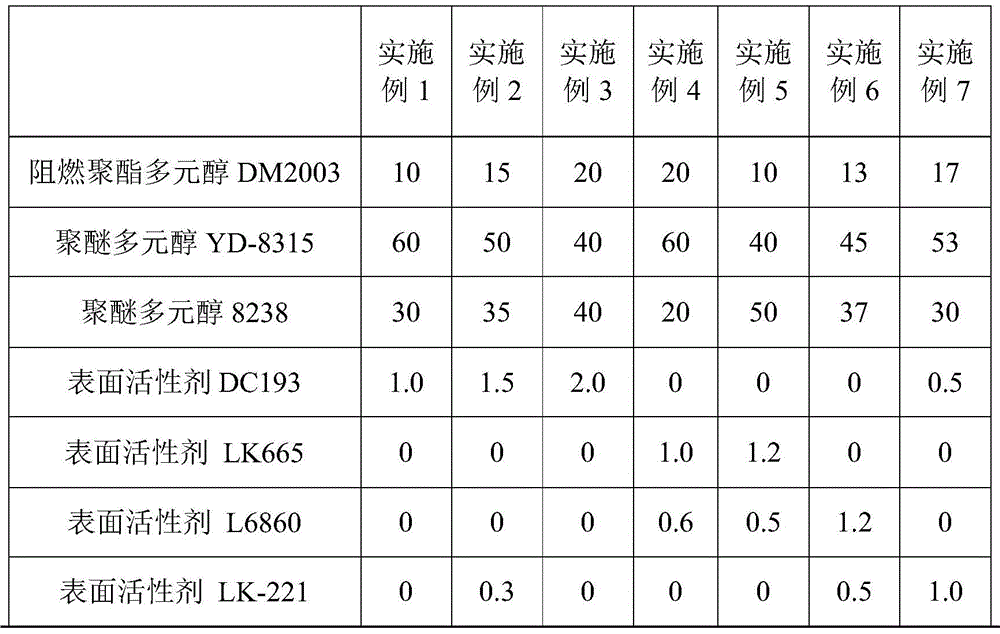

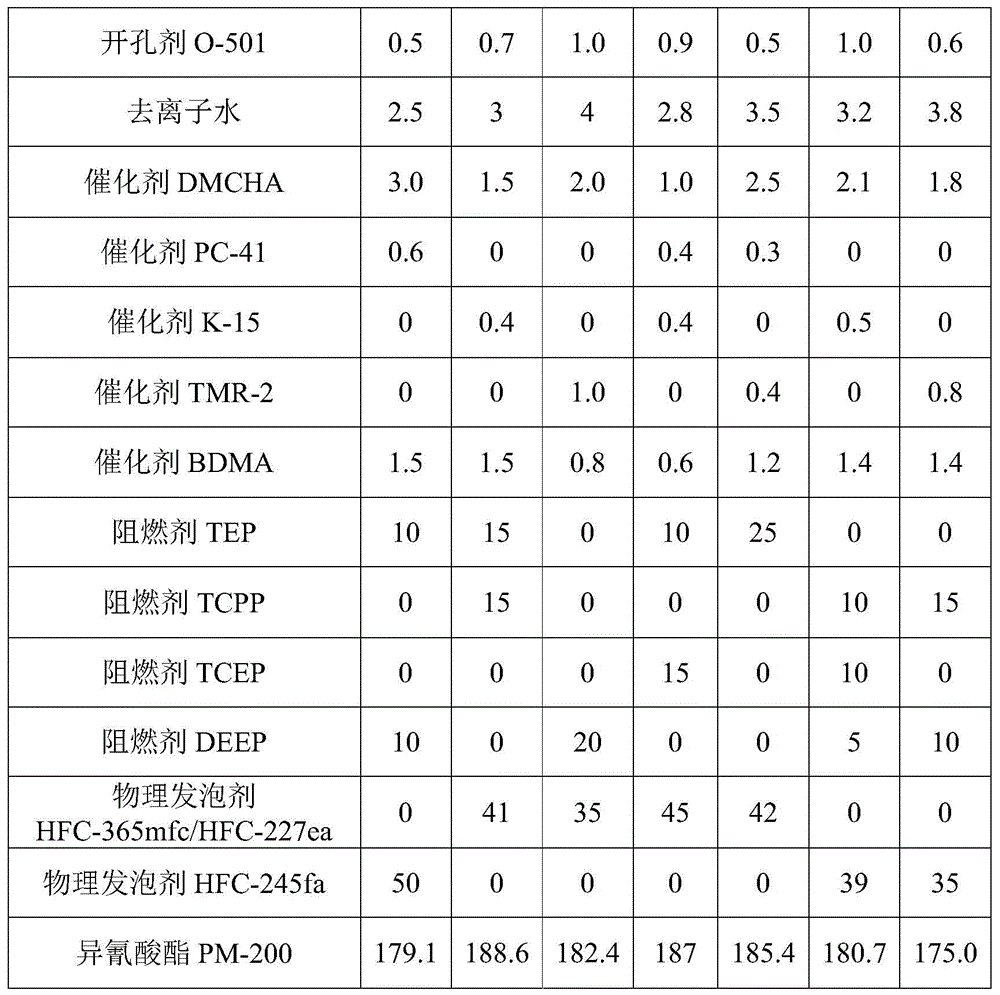

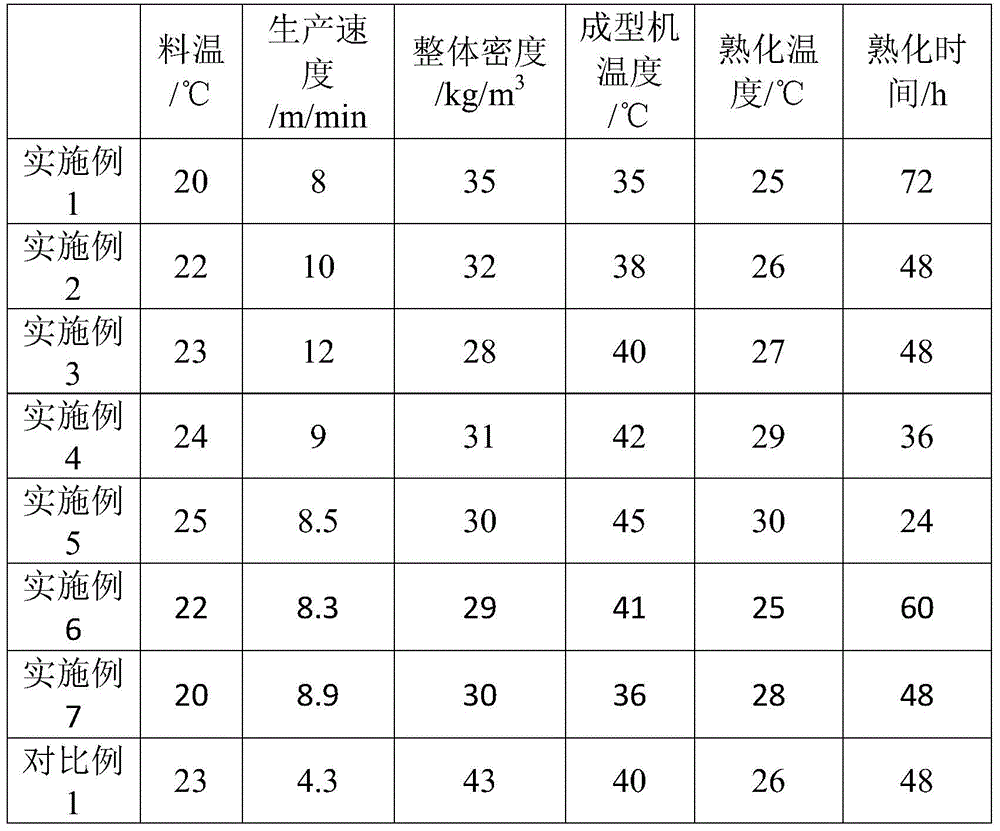

[0058] Table 1 is the raw material formula table of the combined polyether of Examples 1-7, and Table 2 is the raw material formula table of the combined polyether of Comparative Example 1, and all values in the table are parts by weight. In each example and comparative example 1, the components other than isocyanate were mixed evenly to obtain component A, and the isocyanate PM200 was component B.

[0059] Table 1

[0060]

[0061]

[0062] Table 2

[0063] Comparative example 1 Polyether polyol SU-450L 40 Polyether polyol 4110 40 Polyester polyol PS-3152 20 Surfactant B8532 2 h 2 o

1.5 Catalyst DMCHA 2.0 Catalyst PC-41 0.8 Catalyst BDMA 1.0 Flame retardant TCPP 25

[0064] Physical blowing agent HCFC-141b 24 Isocyanate PM200 203.2

[0065] Components other than isocyanate in Table 1 and Table 2 are stirred at room temperature in a stirred tank for 30-60min to obtain A comp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com