Preparation method of Bola type betaine surfactant

A technology of surfactant and betaine, which is applied in the field of chemical preparation, can solve the problems of unreachable industrial production, high cost, and low conversion rate of alkylamide, and achieve the effect of reducing consumption and production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] The preparation method of a kind of Bola type betaine surfactant (Bola type lauryl betaine) of the present embodiment comprises the steps:

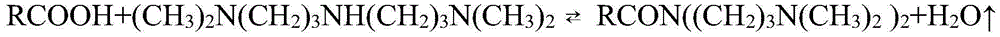

[0024] (1) Preparation of N,N-bis(N,N-dimethylaminopropyl)alkylamide

[0025] A. Put dodecanoic acid and tetramethyldipropylenetriamine in a molar ratio of 1:0.90 into the reactor, heat up to 191°C under the protection of nitrogen, and react for 3 hours under the pressure of 0.35MPa; then vacuumize for 2 hours, vacuum The temperature is kept below -0.095MPa, and the temperature is maintained at 191°C;

[0026] B. Put tetramethyldipropylenetriamine into the reactor of step A again, its molar ratio to alkyl acid is 0.15:1, under the protection of nitrogen, heat up to 191° C., under 0.35MPa pressure, react for 6 hours; Then vacuumize for 6 hours, keep the vacuum degree below -0.095MPa, and keep the temperature at 191°C to obtain N,N-bis(N,N-dimethylaminopropyl)alkylamide; the obtained N,N-bis The acid value of (N,N-dimethylaminoprop...

Embodiment 2

[0031] The preparation method of a kind of Bola type betaine surfactant (Bola type myristyl betaine) of the present embodiment comprises the steps:

[0032] (1) Preparation of N,N-bis(N,N-dimethylaminopropyl)alkylamide

[0033] A. Put tetradecanoic acid and tetramethyldipropylenetriamine with a molar ratio of 1:0.85 into the reactor, heat up to 206°C under the protection of nitrogen, and react for 3.5h under the pressure of 0.50MPa; then vacuumize for 2h, The vacuum degree is kept below -0.095MPa, and the temperature is maintained at 206°C;

[0034] B. Put tetramethyldipropylenetriamine into the reactor of step A again, the molar ratio of it to alkanoic acid is 0.30:1, under the protection of nitrogen, heat up to 206°C, and react for 3h under the pressure of 0.50MPa; Then vacuumize for 3 hours, keep the vacuum degree below -0.095MPa, and keep the temperature at 206°C to obtain N,N-bis(N,N-dimethylaminopropyl)alkylamide; the obtained N,N-bis The acid value of (N,N-dimethylami...

Embodiment 3

[0039] The preparation method of a kind of Bola type betaine surfactant (Bola type oleic acid base betaine) of the present embodiment comprises the steps:

[0040] (1) Preparation of N, N-bis (N, N-dimethylaminopropyl) alkyl amides:

[0041] A. Put oleic acid and tetramethyldipropylenetriamine in a molar ratio of 1:0.95 into the reactor, heat up to 196°C under the protection of nitrogen, and react for 3 hours under the pressure of 0.45MPa; Keep it below -0.095MPa, and keep the temperature at 196°C;

[0042] B. Then put tetramethyldipropylenetriamine into the reactor of step A, and its molar ratio to alkyl acid is 0.10:1. Under the protection of nitrogen, heat up to 200°C and react for 5h under the pressure of 0.50MPa; Then vacuumize for 5 hours, keep the vacuum degree below -0.095MPa, and keep the temperature at 200°C to obtain N,N-bis(N,N-dimethylaminopropyl)alkylamide; the obtained N,N-bis The acid value of (N,N-dimethylaminopropyl) alkylamide was 1.6 mgKOH / g, and the conv...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Acid value | aaaaa | aaaaa |

| Acid value | aaaaa | aaaaa |

| Acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com