Tempered glass breaking device

A technology of tempered glass and crushing device, which is applied in transportation and packaging, special positions of vehicles, and pedestrian/occupant safety arrangement, etc., can solve problems such as obstruction, loss, and small space of swinging a hammer, and achieve the effect of reducing force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

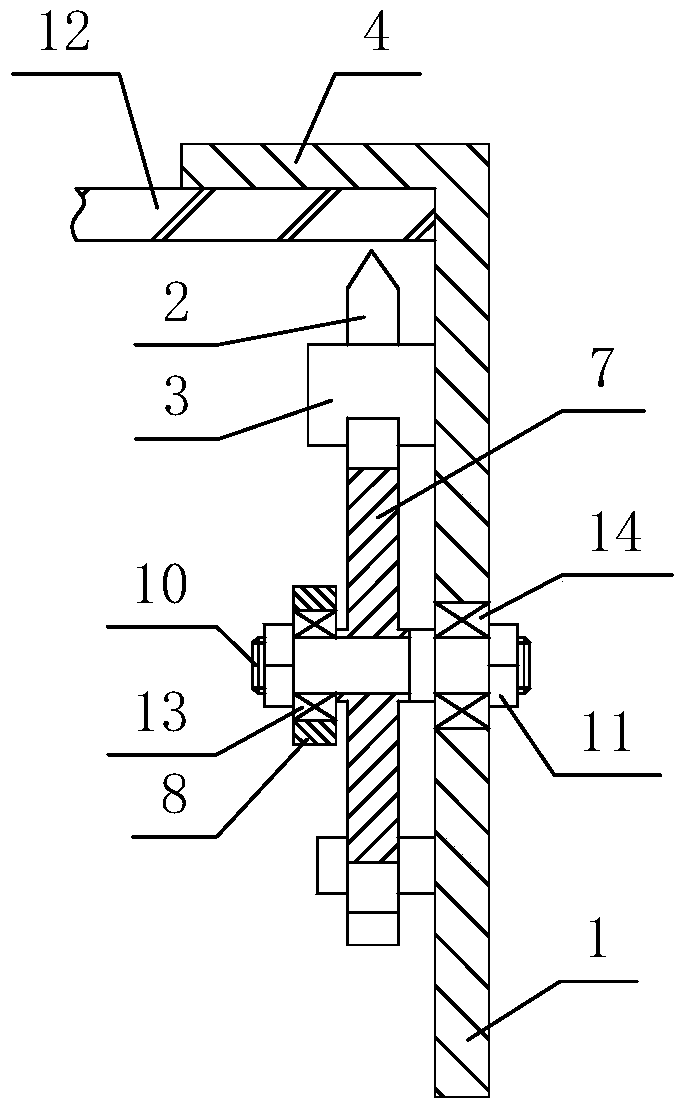

[0034] Such as Figure 1 to Figure 4 As shown, a tempered glass crushing device includes a base 1, a support base 4, a crushing column 2 and a ratchet mechanism. The base 1 is flat, and the support base 4 is fixedly connected to one end of the base 1 .

[0035] The supporting base 4 , the crushing column 2 and the ratchet mechanism are all located on the same side of the base 1 . The supporting surface of broken column 2 vertical support seat 4 is set so that broken column 2 forms vertically with the broken surface of tempered glass 12 after tempered glass 12 is supported on support seat 4, certainly broken column 2 also can be with tempered glass 12 They are relatively inclined, that is, the crushing column 2 is inclined relative to the support seat 4, as long as the purpose of crushing the tempered glass 12 can be achieved. Of course, when the crushing column 2 is set perpendicular to the tempered glass 12, it is most labor-saving. Therefore, in this embodiment, The suppor...

Embodiment 2

[0045] Such as Figure 5 to Figure 9 As shown, a tempered glass crushing device includes a base 1 , a support base 4 , a crushing column 2 , a ratchet mechanism and a gear 15 . The base 1 is flat, and the support base 4 is fixedly connected to one end of the base 1 to form a T-shaped structure with the base 1 . The crushing column 2 and the gear 15 are located on the same side of the base 1 , and the ratchet mechanism is located on the other side of the base 1 . The supporting surface of the vertical support seat 4 of the crushing column 2 is set, the end of the crushing column 2 close to the support seat 4 is the working end, the end point of the working end of the crushing column 2 is point-shaped or linear, and the end point of the working end of the crushing column 2 is made of tempered glass 12 is made of harder materials.

[0046] The projection of the working end of the crushing column 2 to the direction of the supporting surface of the supporting seat 4 is located wi...

Embodiment 3

[0054]Since the breaking column of the present invention requires a relatively small linear motion stroke for breaking the tempered glass, that is to say, the linear velocity of the ratchet or the gear that drives the breaking column is relatively small. Therefore, it is only necessary to swing the active swing lever relatively A small angle can achieve the purpose of breaking tempered glass. In this embodiment, compared with Embodiment 1 and Embodiment 2, the setting of the active pawl will be canceled, and the active swing lever will be fixed directly with the ratchet, so that the operating end of the active swing lever can be directly The ratchet is rotated, and the non-return ratchet still exerts its function of restricting the rotation of the ratchet. The purpose of the present invention can also be achieved.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com