Automobile body system with chassis having stress sensor

A pressure sensor and sensor technology, applied in the field of body systems, can solve the problem of no active action, etc., and achieve the effects of simple structure, reduction of accident losses, and reasonable design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

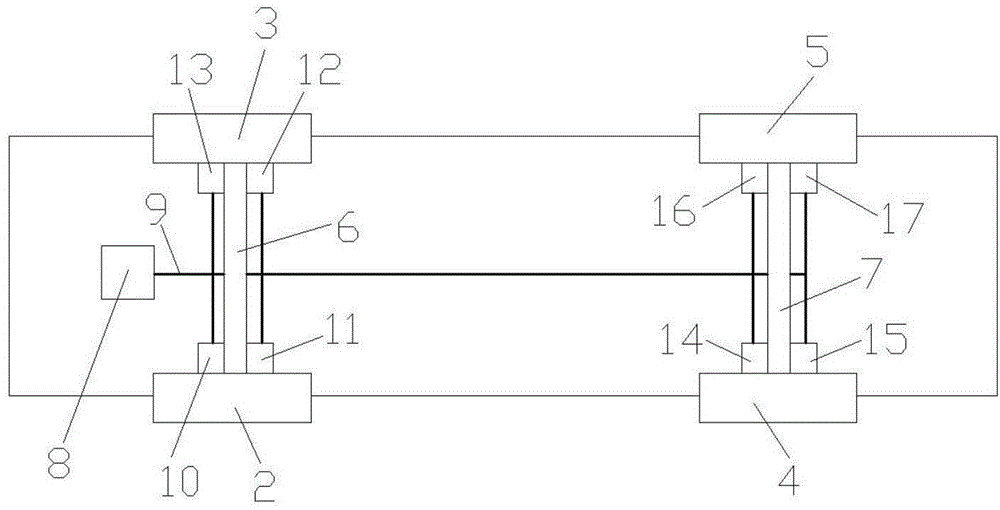

[0012] Examples of the present invention are figure 1 and figure 2 As shown, the present invention includes a vehicle body 1, a first tire 2, a second tire 3, a third tire 4, a fourth tire 5, a front axle 6, a rear axle 7, a controller 8, a wiring harness 9, a first pressure sensor 10, First air release valve 11, second pressure sensor 12, second air release valve 13, third pressure sensor 14, third air release valve 15, fourth pressure sensor 16, fourth air release valve 17, front end force sensor 18. Rear end force sensor 19, roof force sensor 20, chassis force sensor 21, the first tire 2 and the second tire 3 are arranged at the front of the vehicle body 1 and connected by the front axle 6, the third tire 4 , the fourth tire 5 is arranged at the rear of the vehicle body 1 and is connected by the rear axle 7, the controller 8 is arranged at the front of the vehicle body 1, and the first pressure sensor 10 and the first deflation valve 11 are all arranged on the first tire ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com