A wood-plastic composite material production unit

A technology of wood-plastic composite materials and units, which is applied in the field of production units and can solve problems such as difficulty in controlling foaming and molding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

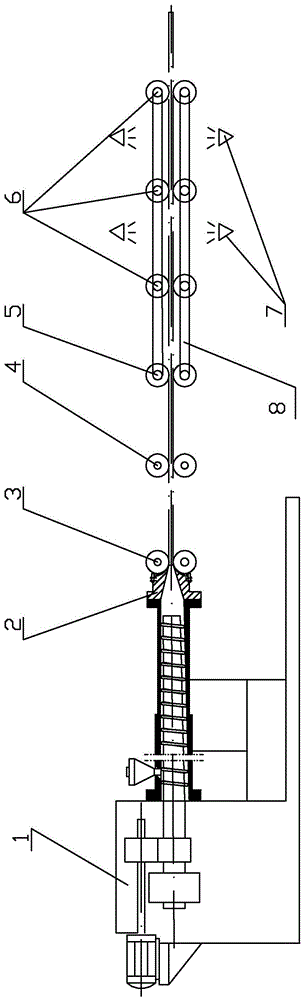

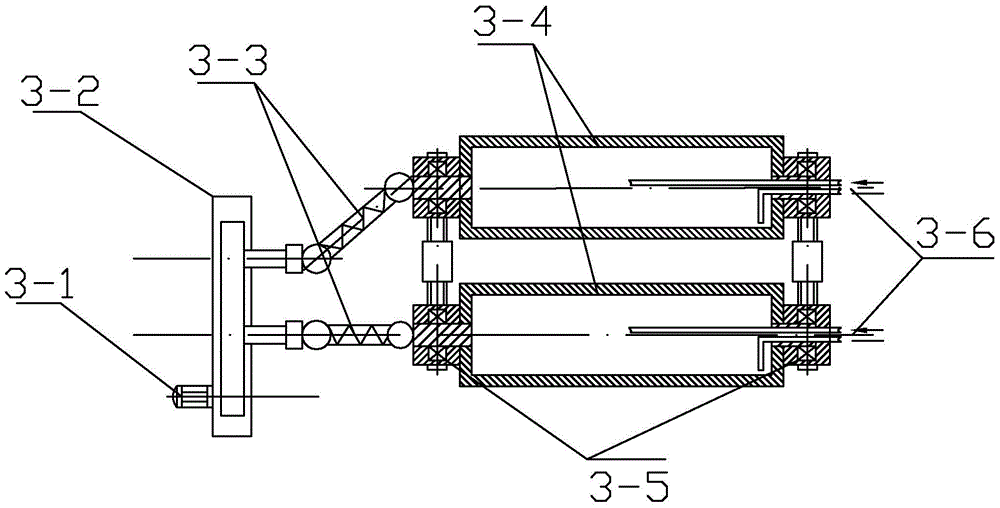

[0024] Specific implementation mode one: combine figure 1 figure 2 , image 3 and Figure 4 To illustrate this embodiment, a wood-plastic composite material production unit of this embodiment includes a wood-plastic composite material extruder 1, and the wood-plastic composite material production unit also includes an extrusion die 2, a cooling guide roll 3, a heating calender roll 4, Active cooling sizing roll 5, multiple passive cooling sizing rolls 6, multiple cooling water spray devices 7 and transmission assembly 8, extrusion die 2 is installed at the output end of wood-plastic composite material extruder 1, cooling guide roll 3 and The heating calender rolls 4 are sequentially arranged at the exit end of the extrusion die 2 from left to right, the structure of the cooling guide roll 3 and the heating calender roll 4 is the same, and the transmission assembly 8 is connected with the active cooling sizing roll 5 and the passive cooling sizing roll 6. A cooling water sp...

specific Embodiment approach 2

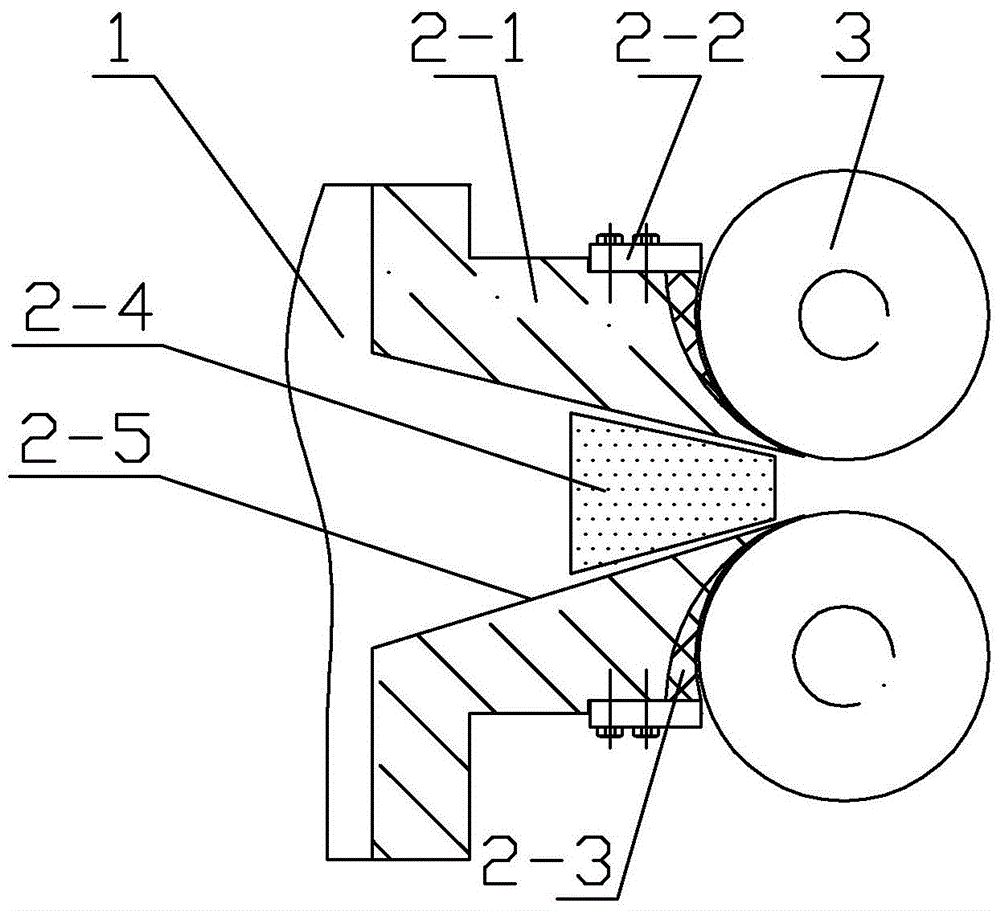

[0025] Specific implementation mode two: combination figure 1 and figure 2 To illustrate this embodiment, the extrusion die 2 of this embodiment includes a discharge port module 2-1, a sealing pad bead 2-2, a sealing pad 2-3 and a replaceable cushion block 2-4, and the discharge port module 2-1 There is a tapered hole 2-5 in the middle of the center, and the gasket 2-3 is installed between the outlet end of the outlet module 2-1 and the cooling guide roller 3 through the gasket bead 2-2, and the replaceable pad 2-4 is installed At the outlet of outlet module 2-1. With such an arrangement, by replacing the replaceable pads with different thicknesses and widths, the discharge state of the discharge port can be changed to form discharges with different thicknesses and widths, so as to meet the needs of products with different widths and thicknesses. Other compositions and connections are the same as in the first embodiment.

specific Embodiment approach 3

[0026] Specific implementation mode three: combination figure 2 To describe this embodiment, the outer end surface of the outlet of the outlet module 2-1 of this embodiment is provided with a concave arc surface. Such setting facilitates the engagement with the cooling guide roller 3 . Other compositions and connections are the same as those in Embodiment 1 or Embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com