Aero-engine assembly measuring system two-dimensional driving device based on plane orthogonal decoupling

An aero-engine and assembly measurement technology, applied to workbenches, manufacturing tools, etc., can solve problems such as difficult to achieve high motion accuracy and high positioning stability of adjustment devices, so as to improve assembly and measurement efficiency, reduce system loss, and improve The effect of stability and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

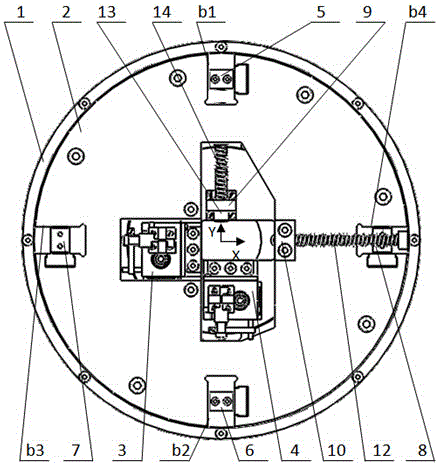

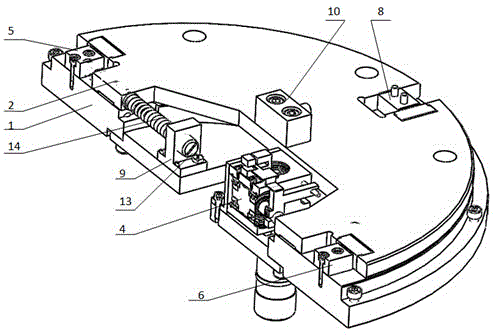

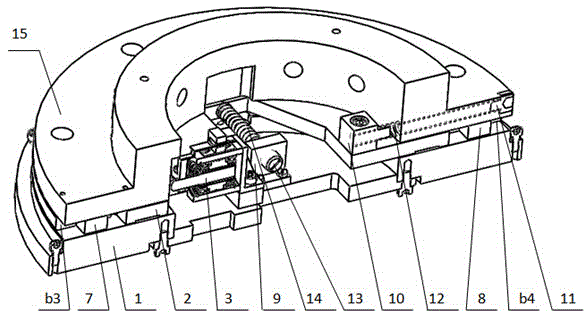

[0029] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0030] A two-dimensional driving device for an aero-engine assembly measurement system based on plane orthogonal decoupling, comprising a base 1 , a tray 2 and a table 15 , and the tray 2 is disposed between the base 1 and the table 15 .

[0031]On the base 1 along the Y axis, there are sequentially connected the Y-direction guide block A6, the Y-direction motor 4, the Y-direction spring seat 9 and the Y-direction guide block B5; The guide groove b1 is in contact and fit, and the Y-direction guide block A6 is in contact with the guide groove b2 on the tray 2; the Y-direction spring seat 9 is equipped with a Y-direction adjustment screw 13, and the Y-direction adjustment screw 13 is equipped with a The Y-direction spring 14 is connected with the tray 2 ; the Y-direction motor 4 is connected with the tray 2 and provides driving force for the tray 2 .

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com