A material conveying mechanism for ferrule workpiece processing

A technology for conveying mechanisms and workpieces, which is applied to metal processing equipment, manufacturing tools, and parts of grinding machine tools. It can solve the problems of large space occupation, inconvenience, and damage to ferrules, and achieve the effect of small space occupation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The following describes the present invention in detail with reference to the accompanying drawings and specific preferred embodiments, so that the advantages and features of the present invention can be more easily understood by those skilled in the art. These embodiments are for illustrative purposes only, and are not intended to improve the present invention. The scope is limited.

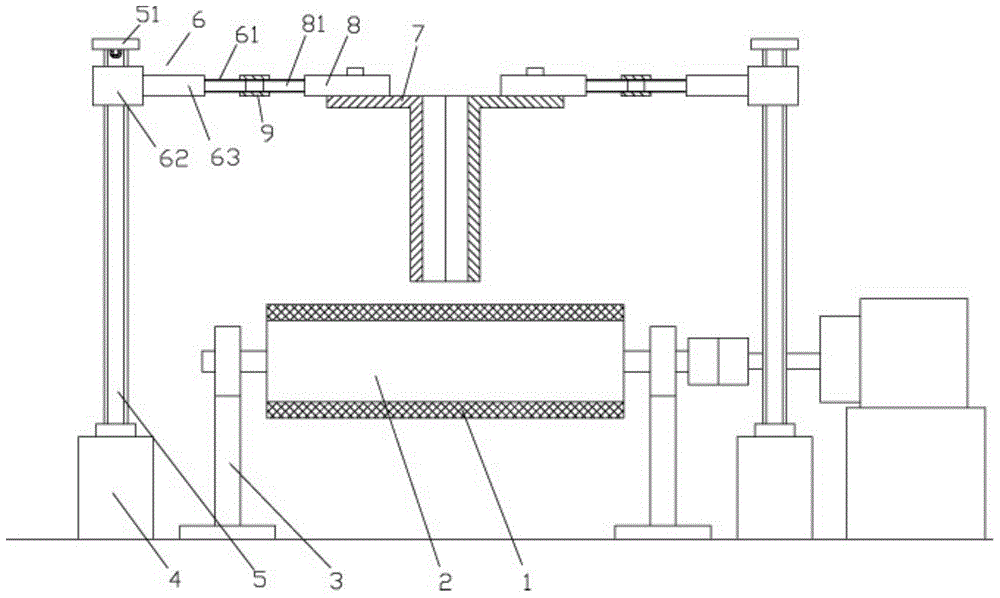

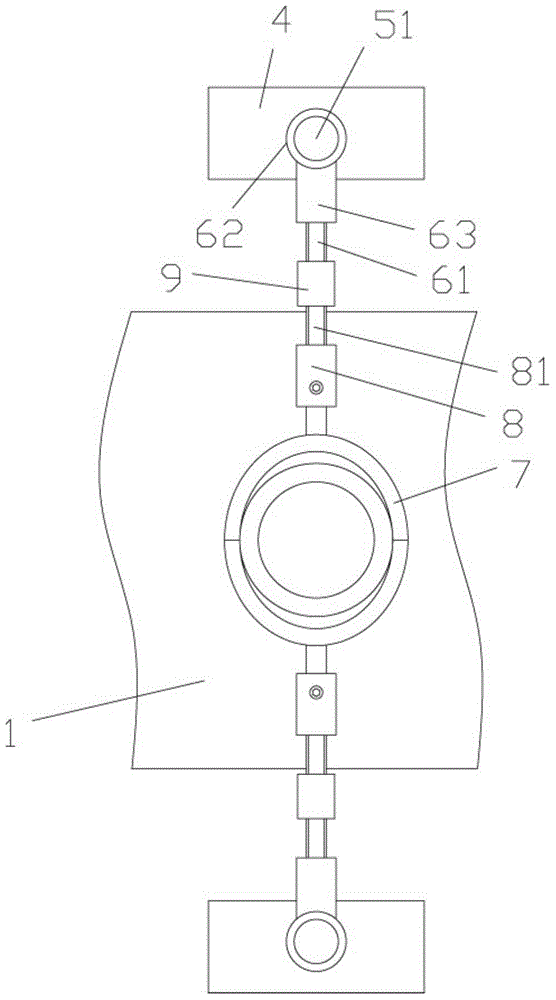

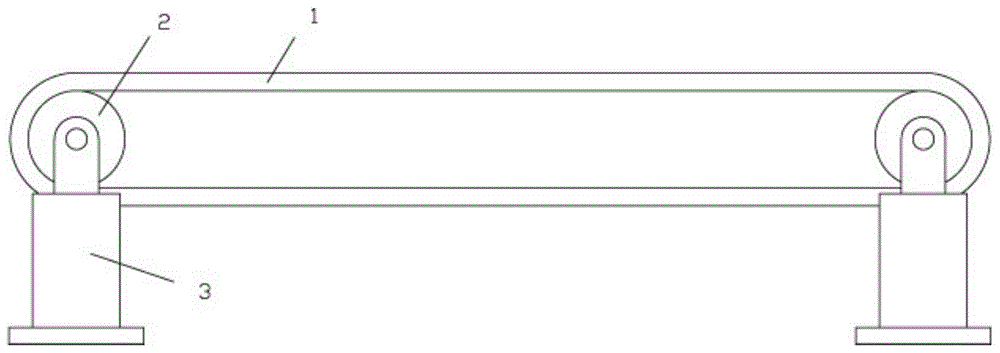

[0021] Example, see as Figure 1 to Figure 3 As shown, a ferrule workpiece processing and unloading conveying mechanism includes a conveyor belt 1. The conveyor belt 1 is tensioned between two rotating rollers 2, and the two rotating rollers 2 are fixed with support seats 3 at both ends, one of which One end of the rotating roller 2 extends out of the support base 3 and is connected to the output shaft of the drive motor through a coupling; connecting blocks 4 are fixed on both sides of the conveyor belt 1, and the upper end of the connecting block 4 is hinged with a rotating screw 5, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com