Welding processing method and tooling for fan case assembly

A fan casing and processing method technology, applied in welding equipment, welding equipment, auxiliary welding equipment, etc., can solve the problems of difficult blade body protection, large dimensional error, poor welding seam forming quality, etc., and achieve remarkable protection effect, welding The process is stable and controllable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

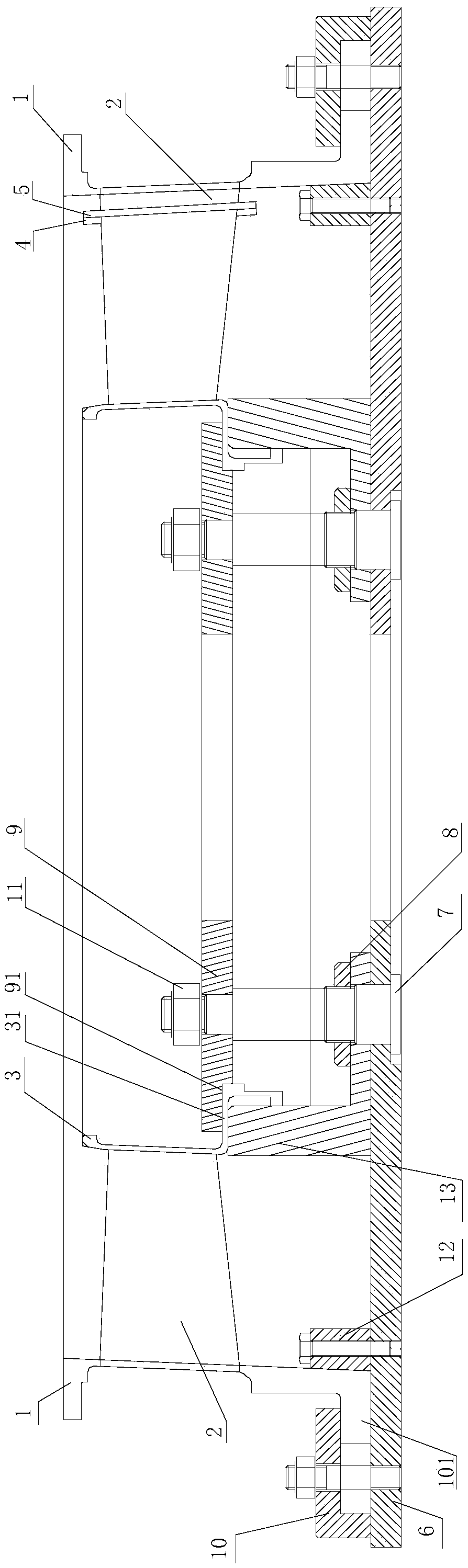

[0044] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

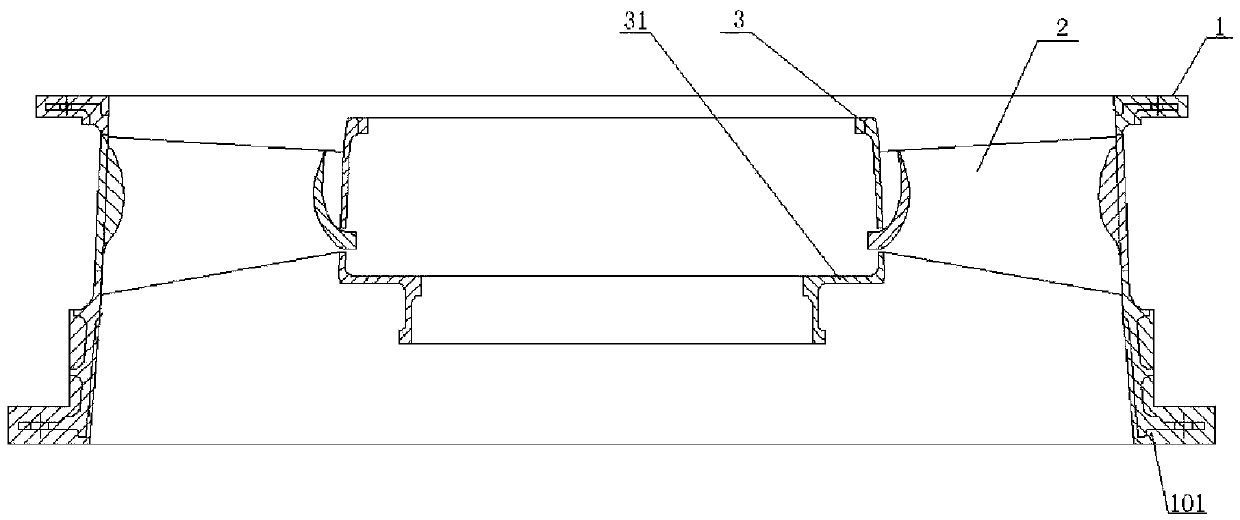

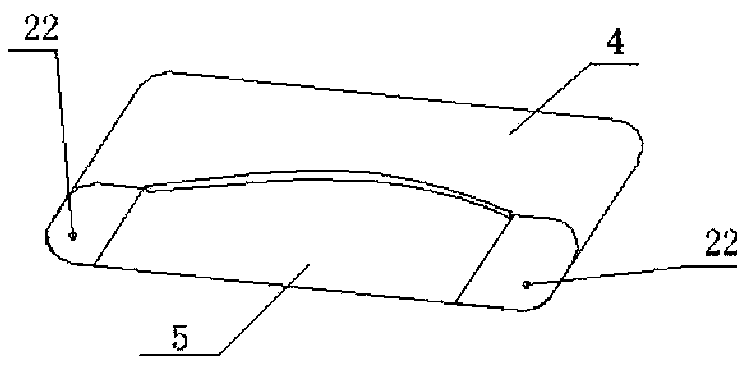

[0045] Such as Figure 1~4 As shown, a welding processing method for a fan casing assembly specifically includes the following steps:

[0046] Step 1: Preparation before welding

[0047] Gather all the components of the fan casing assembly: outer ring 1, blade 2 and inner ring 3, the diameter of outer ring 1 is reserved for 1.2mm, and the deformation of outer ring 1 is reserved for welding; outer ring 1, blade 2 and inner ring 1 The ring 3 is pickled to remove the oxide layer; the outer ring 1 and the inner ring 3 are fixed on the welding fixing tool, and then the blades 2 are assembled on the inner and outer rings one by one to form a fan case assembly;

[0048] The process of fixing the outer ring 1 and the inner ring 3 on the welding fixture: place the inner ring 3 on the support ring 13, cover the step 31 of the inner ring 3 wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com