Manufacturing method of sand leaking preventing and heat preserving feed head of sand casting and special die thereof

A technology for thermal insulation risers and sand castings, which is applied to the production method of sand leakage-proof thermal insulation risers for sand castings and the field of special molds, can solve the problems of scrap castings, increase the cleaning workload, etc., and achieve the effect of accurate embedding and positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

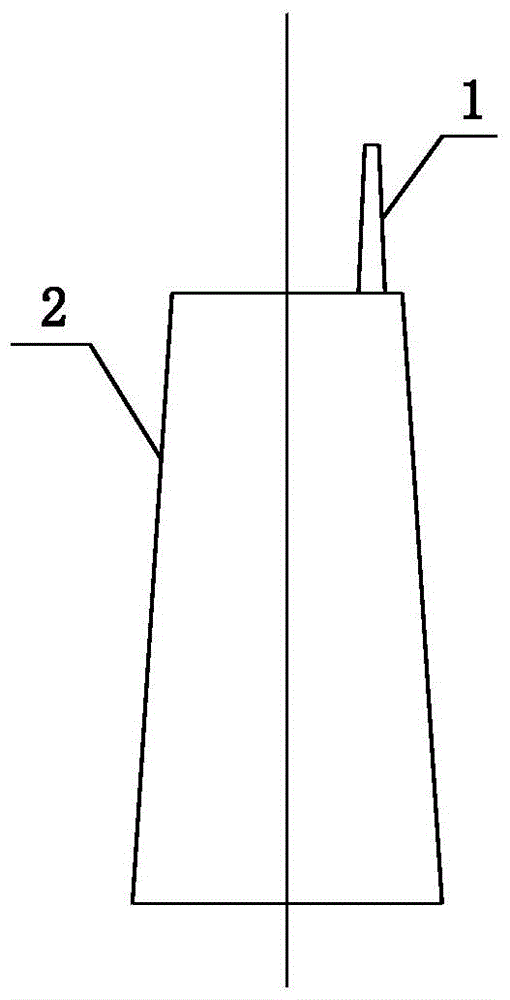

[0025] figure 1 , 2 The traditional riser mold and the riser structure formed by it have been introduced in detail in the background art, and will not be repeated here.

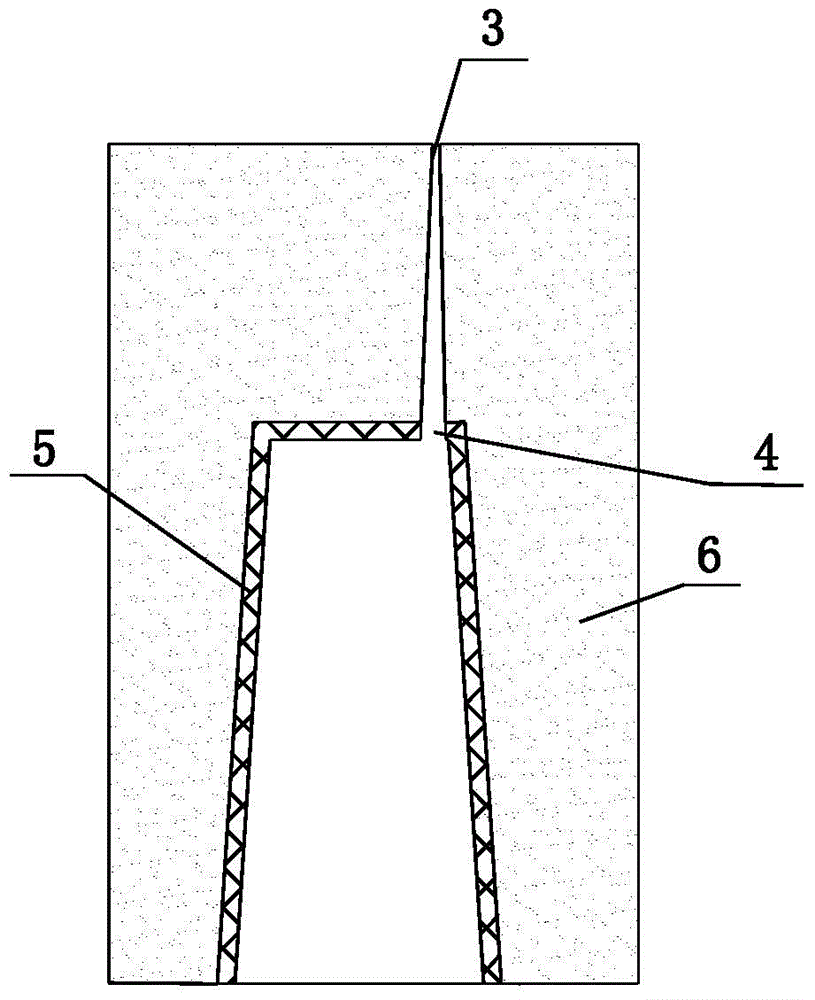

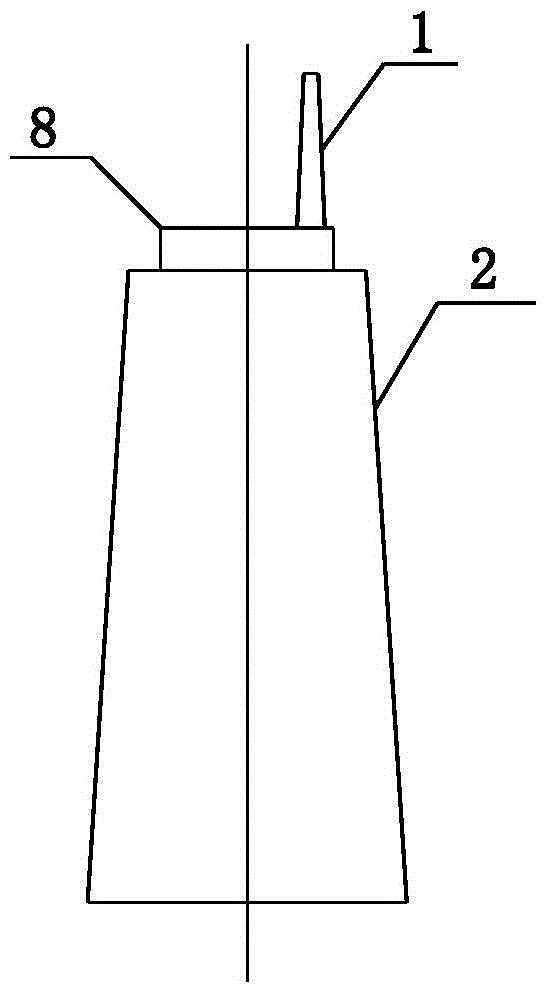

[0026] image 3 Shown is the special mold for the anti-leakage sand insulation riser of sand castings of the present invention. Figure 4~5 It is a schematic diagram of the sand mold structure of the riser made by using the special mold for the riser. This riser special mold is mainly made up of riser mold base 2, anti-leakage sand platform 8, riser outlet air rod 1 and riser insulation cover 5. The riser mold base 2 is in the shape of a thick truncated cone, and is attached to the casting body mold when making the riser sand mold; the anti-leakage sand platform 8 is in the shape of a thin disc or a thin truncated cone, and is installed on the top of the riser mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com