Valve body forging method

A valve body and forging technology, which is applied in the field of valve body manufacturing, can solve the problems of energy saving and consumption reduction, the difficulty of full die forging, and high mold requirements, and achieve the effects of material saving, excellent mechanical properties, and simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

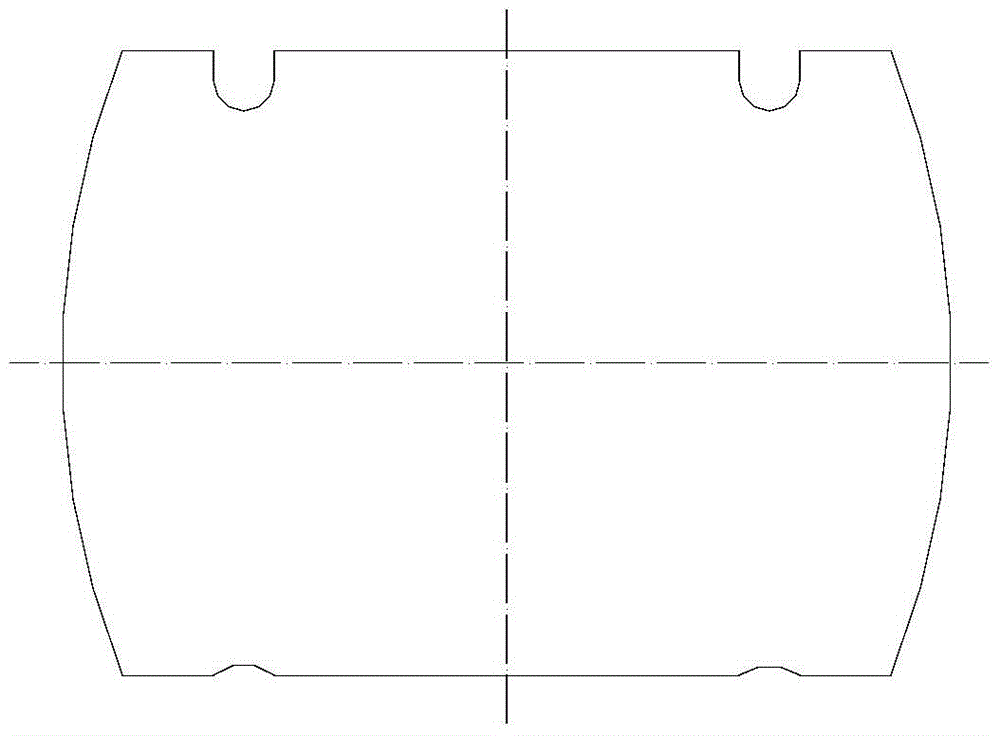

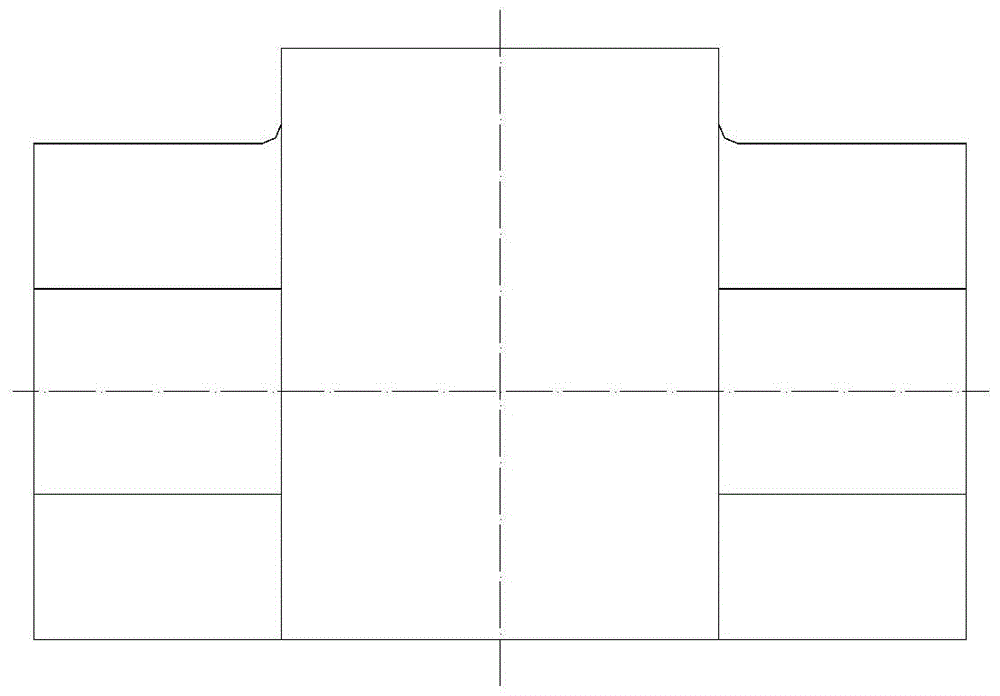

Image

Examples

Embodiment 1

[0052] The blanked 35CrMo alloy steel billet (420×320×260) is first freely forged with a 3T forging hammer to 410×310×250mm, the two ends are riveted and forged, and the indentation is divided into two ends, and the eccentricity is forged. , and then forge both ends into a 260° octagon, and use a pressing block to groove the part of the octagon close to the square with a length of 50mm to a length of 165×165×85mm to ensure that the end flange is 80mm long and the groove is 85mm long; then use up and down crimping The middle octagon is forged by means of dies. Be careful not to reverse the direction. Correct the middle square when buckling the octagon. Control the height of the middle square to 305mm and the width to 250mm to ensure a length of 250mm-260mm. After the middle square is forged in place, the flanges at both ends Control the height of the forging circle with spacers. Finally, the size of each part is corrected to the size shown in the forging drawing, and the flange...

Embodiment 2

[0056] The blanked 30CrMo alloy steel billet (420×320×260) is first freely forged to 410×310×250 with a 3T forging hammer, and the two ends are riveted and forged, and the indentation is divided to separate the two ends, and the eccentricity is forged. Then forge both ends into a 260° octagon, and use a pressing block to groove the part of the octagon close to the square with a length of 50mm to a length of 165×165×85mm to ensure that the length of the end flange is 80mm and the length of the groove is 85mm; then use the upper and lower crimping dies Forge the middle octagon in the same way, pay attention not to reverse the direction, correct the middle square when buckling the octagon, control the height of the middle square to 305mm and the width of 250mm, and ensure the length of 250mm-260mm; after the middle square is forged in place, use the flanges at both ends The spacer controls the height of forged circle. Finally, the size of each part is corrected to the size shown ...

Embodiment 3

[0060] The blanked 35CrMo alloy steel billet (620×520×460) is first freely forged with a 3T forging hammer to 610×510×450mm, the two ends are riveted and forged, and the indentation is divided into two ends, and the eccentricity is forged. , and then forge both ends into a 260° octagonal, use a pressing block to press the part of the octagonal 80mm long to 265×265×1055mm long, ensure that the end flange is 100mm long, and the groove is 105mm long; then use up and down crimping Forge the middle octagon by means of mold, pay attention not to reverse the direction, correct the middle square when buckling the octagon, control the height of the middle square to 405mm and the width of 350mm, and ensure the length of 350mm-360mm; Control the height of the forging circle with spacers. Finally, the size of each part is corrected to the size shown in the forging drawing, and the flanges at both ends are controlled on the same axis, and the eccentricity between the octagonal block in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com