A fully automatic cleaning system for large load parts

A fully automatic cleaning, heavy load technology, applied in cleaning methods and utensils, cleaning methods using liquids, dryers, etc., can solve the problems of difficult cleaning, long time consumption, harsh working environment, etc., to improve the automation of the system , The effect of reducing cycle time and saving manpower and material resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

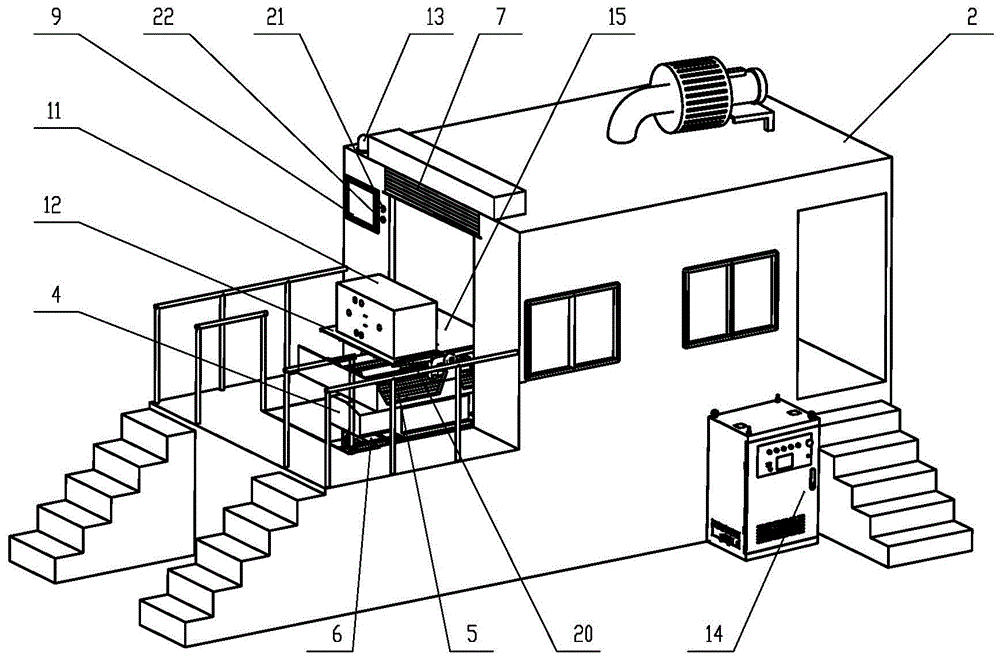

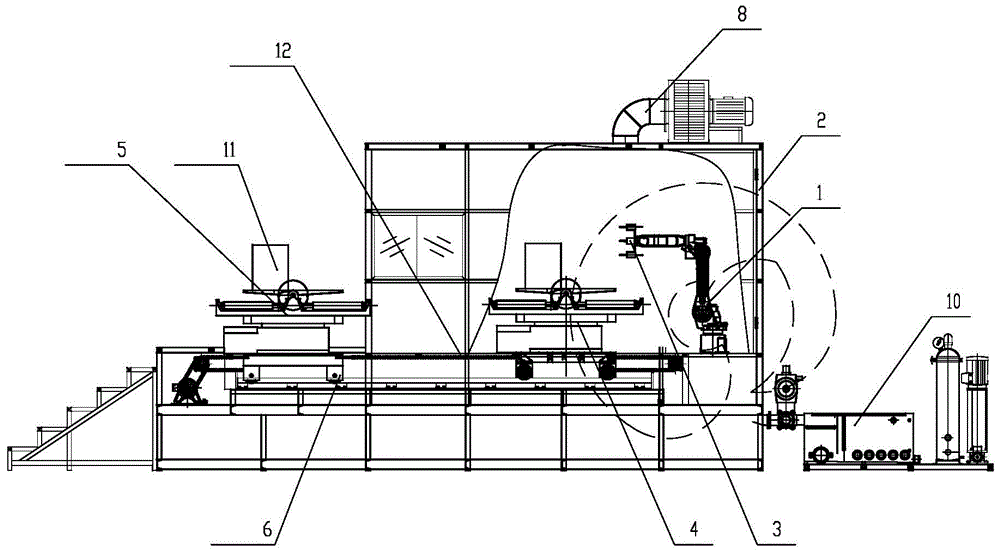

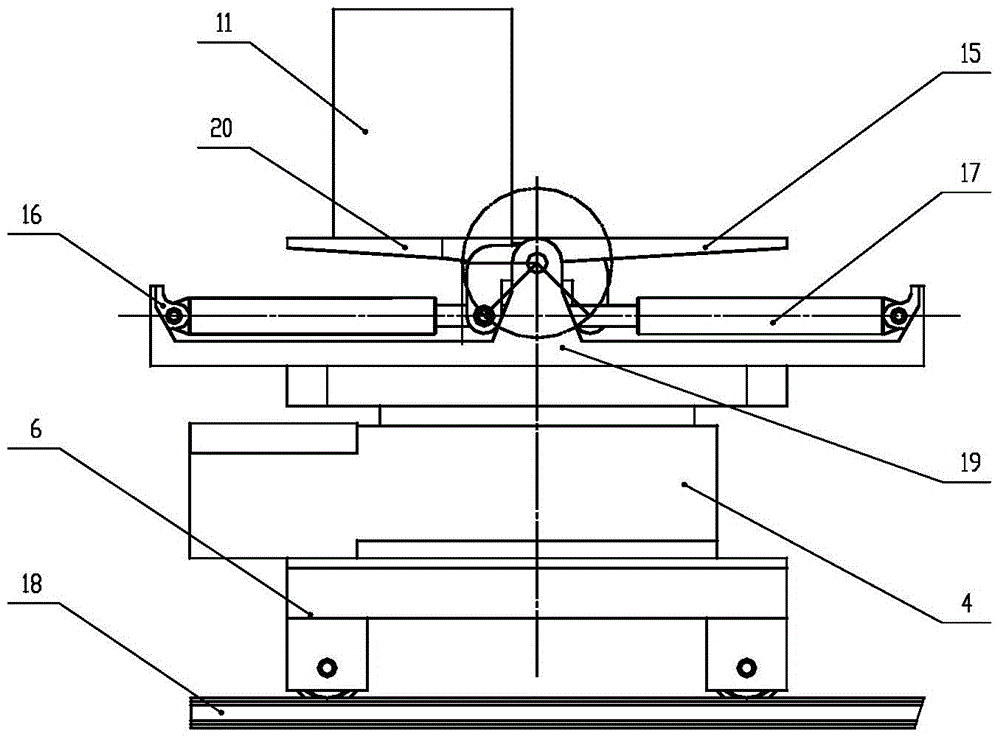

[0012] to combine figure 1 , figure 2 , a fully automatic cleaning system for large-load parts, including a cleaning cabin 2, a cleaning device, a feeding track trolley 6, a rolling door 7, ventilation equipment 8, a display setting user terminal 9, and a filter heating pump circulation system 10.

[0013] A feed door is arranged on one side of the cleaning cabin 2, and a rolling shutter door 7 is arranged at the feed door.

[0014] The cleaning device is set in the cleaning cabin 2 and away from the end of the feed door, including the joint robot 1, the gripper 3, and the rinse gun. The gripper 3 is arranged on the end flange of the joint robot 1, and the gripper 3 is provided with a rinse gun. Based on actual operating requirements, a six-axis industrial robot that meets the operating space and adapts to the environment is selected. The drive motors of all joints are connected to the high-speed industrial bus through the driver, and the motion controller realizes the contr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com