Anti-blocking coal slurry screening equipment

The utility model relates to a coal slurry screening equipment and coal slurry technology, which can be applied in the direction of filter screen, solid separation, grille, etc., and can solve the problems such as time-consuming, labor and production cost, clogging of the screen, affecting the coal slurry screening effect, etc. Achieve the effect of avoiding blockage, reducing pressure difference between upper and lower, and keeping clean

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

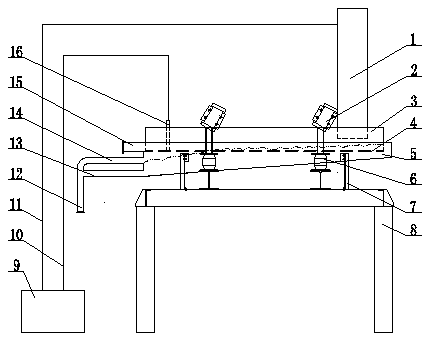

[0007] Referring to the drawings as follows, the anti-blocking coal slurry screening equipment includes feeding trough 1, motor 2, coal slurry sieve body 3, screen 4, coal slurry regulating tank 5, and coal slurry sieve support 6 with composite springs , coal slurry adjustment tank fixed pillar 7, coal slurry screen platform 8, liquid level sensor adjustment device 9, liquid level signal transmission cable 10, liquid level control cable 11, qualified coal slurry outlet main pipe 12, qualified coal slurry outlet branch pipe 13, Qualified coal slurry overflow pipe 14, large particle coal discharge pipe 15, liquid level measuring device 16.

[0008] It is characterized in that: the motor 2 and the coal slurry screen tank body 3 are fixed on the upper part of the coal slurry screen support 6 with composite springs, and the coal slurry adjustment tank 5 is fixed on the upper part of the coal slurry adjustment tank fixed pillar 7 . The coal slurry screen support 6 with composite spr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com