Micro heater

A micro-heater and micro-channel technology, applied in the field of micro-electromechanical systems, can solve the problems of high price, complex production equipment, uneven heating temperature, etc., and achieve the effect of low cost and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

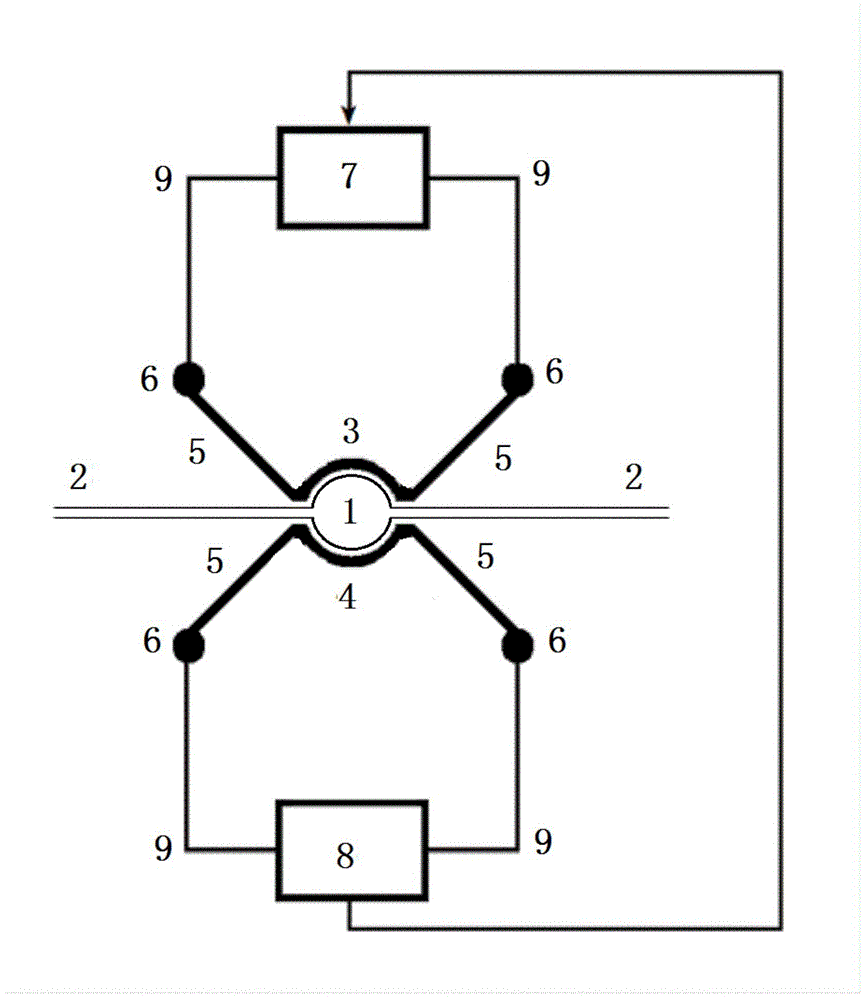

[0027] Such as figure 1 As shown, this embodiment provides a micro heater, including a reaction chamber 1, a sample microchannel 2, the sample microchannel 2 leads to the reaction chamber 1, and at least two arc-shaped microchannels with the same arc;

[0028] The reaction chamber 1 is surrounded by at least two arc-shaped micro-channels with the same radian. direct contact.

[0029] Specifically, an insulating material with low thermal conductivity can be filled between at least two arc-shaped micro-channels, and an insulating material with low thermal conductivity can be filled between at least two arc-shaped micro-channels and the reaction chamber 1 . The reaction chamber 1 is a microenvironment with a constant and uniform temperature, and the sample microchannel 2 is a channel for taking and placing the test substance into the reaction chamber 1 . At least two arc-shaped micro-channels with the same radian can be figure 1 The arc-shaped micro-channel 3 and the arc-shape...

Embodiment 2

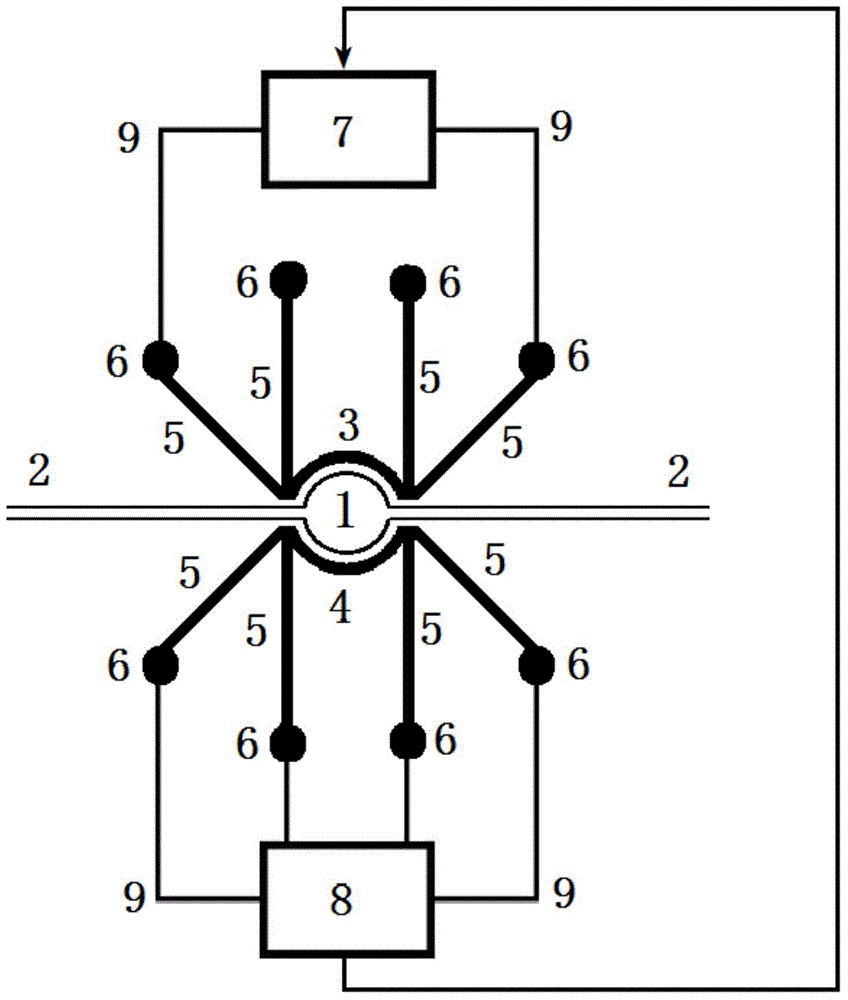

[0049] Such as figure 2As shown, this embodiment provides a micro-heater, including a reaction chamber 1, a sample micro-channel 2, an arc-shaped micro-channel 3 and an arc-shaped micro-channel 4 with the same radian, a hollow lead wire 5, and an infusion port 6 , power module 7, temperature control module 8.

[0050] Among them, the reaction chamber 1 is used to provide the constant temperature environment required by the test object; the sample microchannel 2 leads to the reaction chamber 1, and is used to inject and take the test substance into the reaction chamber 1; the arc-shaped micro-channel 3, the arc-shaped The micro-channel 4 is used to provide a heat source to the reaction chamber 1 and / or measure the temperature of the reaction chamber 1; the hollow lead wire 5 is used to connect the arc-shaped micro-channel 3 and the arc-shaped micro-channel 4 to the filling port 6; the filling port 6 is used to pour liquid metal into the arc-shaped micro-channel 3 and the arc-...

Embodiment 3

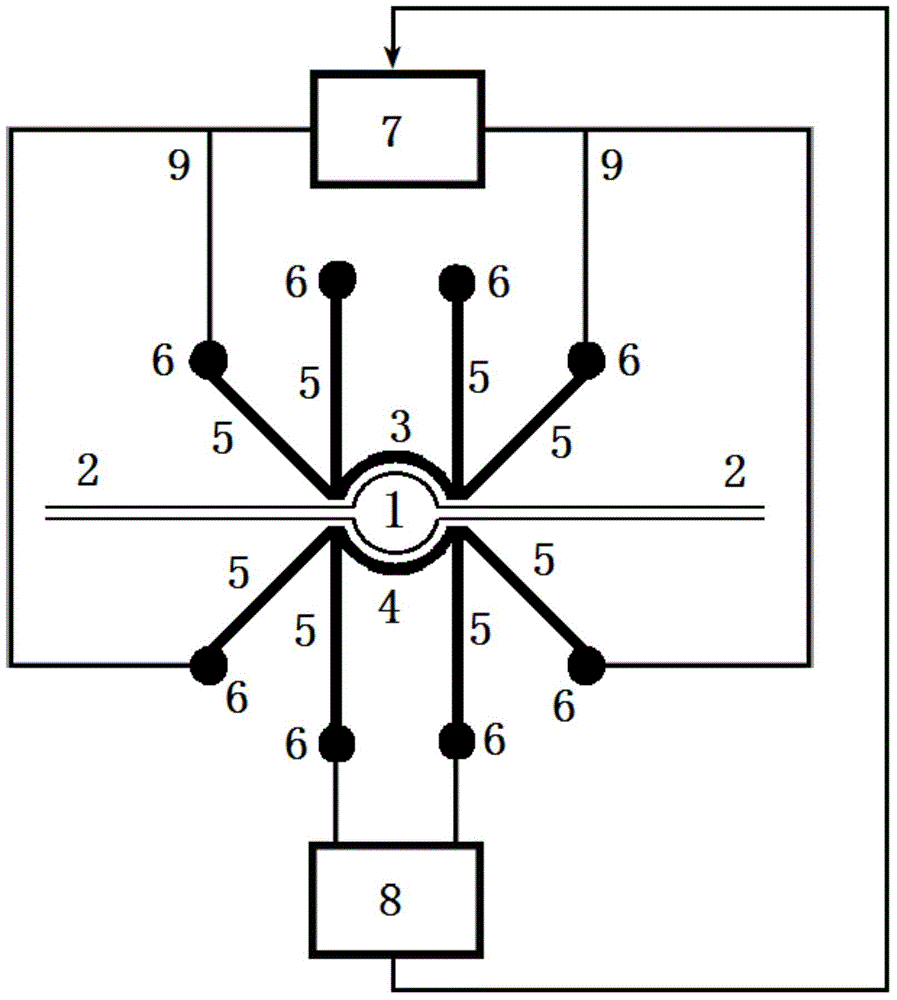

[0058] Such as image 3 As shown, this embodiment provides a micro-heater, including a reaction chamber 1, a sample micro-channel 2, an arc-shaped micro-channel 3 and an arc-shaped micro-channel 4 with the same radian, a hollow lead wire 5, and an infusion port 6 , power module 7, temperature control module 8.

[0059] Among them, the reaction chamber 1 is used to provide the constant temperature environment required by the test object; the sample microchannel 2 leads to the reaction chamber 1, and is used to inject and take the test substance into the reaction chamber 1; the arc-shaped micro-channel 3, the arc-shaped The micro-channel 4 is used to provide a heat source to the reaction chamber 1 and / or measure the temperature of the reaction chamber 1; the hollow lead wire 5 is used to connect the arc-shaped micro-channel 3 and the arc-shaped micro-channel 4 to the filling port 6; the filling port 6 is used to pour liquid metal into the arc-shaped micro-channel 3 and the arc-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com