Emulsification method and emulsification device for lead-acid battery colloidal electrolyte thickener

A colloidal electrolyte, lead-acid battery technology, applied in chemical instruments and methods, mixers with rotary stirring devices, dissolution and other directions, can solve problems such as agglomeration and deposition, and achieve the promotion of dissolution and mixing, high efficiency, and prevention of deposition. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

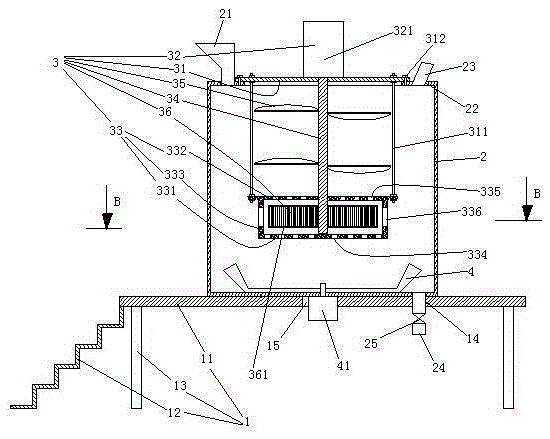

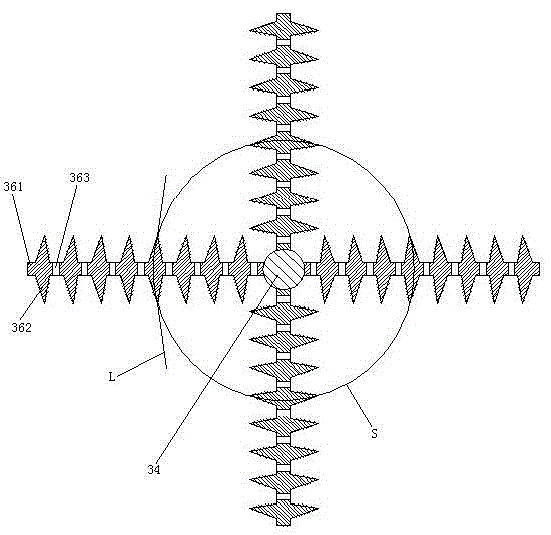

[0041] Embodiment one, see figure 1 , an emulsification device, including a support table 1, a container 2 and a stirrer 3.

[0042] The support platform 1 includes a panel 11 and a staircase 12 . The upper end of the stairs 12 is connected with the panel 11. The panel 11 is provided with supporting feet 13 , discharge holes 14 and motor through holes 15 .

[0043] A feed hopper 21 and an observation port 22 are provided on the top wall of the container 2 . The observation port 22 is fixedly connected with an observation tube 23 . The bottom wall of the container 2 is provided with a discharge pipe 24 . The discharge pipe 24 extends to the lower space of the panel 11 through the discharge hole 14 . The discharge pipe 24 is provided with a discharge valve 25 . The discharge valve 25 is an electric valve. The container 2 rests on the panel 11 . A wall scraping paddle 4 is also provided in the container 2 . The wall-scraping paddle 4 is attached to the inner surface of t...

Embodiment 2

[0051] Embodiment two, the difference with embodiment one is:

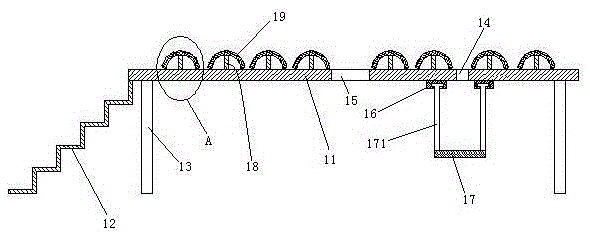

[0052] see image 3 , The upper surface of the panel 11 is provided with several supporting protrusions 18 . The height of the supporting protrusion 18 is less than 2 centimeters. The upper end of the support protrusion 18 is connected with a suction cup 19 . The suction cup 19 is turned down to the opening facing downwards and covered on the support protrusion 18 . A bracket 17 is provided below the panel 11 . A slide rail 16 is provided on the lower surface of the panel 11 . There are two slide rails 16. The slide rail 16 extends to the edge of the panel 11 . The discharge hole 14 is located between two slide rails 16 . The bracket 17 is provided with two hanging arms 171 . The lower ends of the two hanging arms 171 are connected to the two ends of the bracket 17 . The upper ends of the two hanging arms 171 are slidably suspended on the two slide rails 16 in a one-to-one correspondence.

[0053] see ...

Embodiment 3

[0056] Embodiment three, the difference with embodiment two is:

[0057] see Image 6 , The agitator also includes a lifting mechanism 37. The quantity of lifting mechanism 37 is equal to the quantity of stirring blade 35. The lifting mechanism 37 includes a chute 371 , a slider 372 , a screw rod 373 and a lifting motor 374 . The slide slot 371 is disposed on the rotating shaft 34 . The slide slot 34 extends axially along the rotating shaft 34 . The sliding block 372 is slidably connected in the slide groove 371 . The stirring blades 35 and the sliders 372 are connected together in a one-to-one correspondence. The screw rod 373 extends in the vertical direction. The threaded rod 372 is screwed to the slider 372 and passes through the slider 372 . The power output shafts of the screw mandrel 373 and the lifting motor 374 are coaxial and connected together. The lift motor 374 is connected to the upper end of the rotating shaft 34 .

[0058] The shaft driving mechanism 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com