Modifier for scrap brass and method for producing brass alloy using it

A modifier and miscellaneous brass technology, which is applied in the field of waste miscellaneous brass modifiers to produce high-performance brass alloys. It can solve problems such as inappropriate ingredients and feeding technology, low metal recovery rate, and loss of metal elements. , to achieve the effects of excellent performance and process performance, smooth surface and low burning loss rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

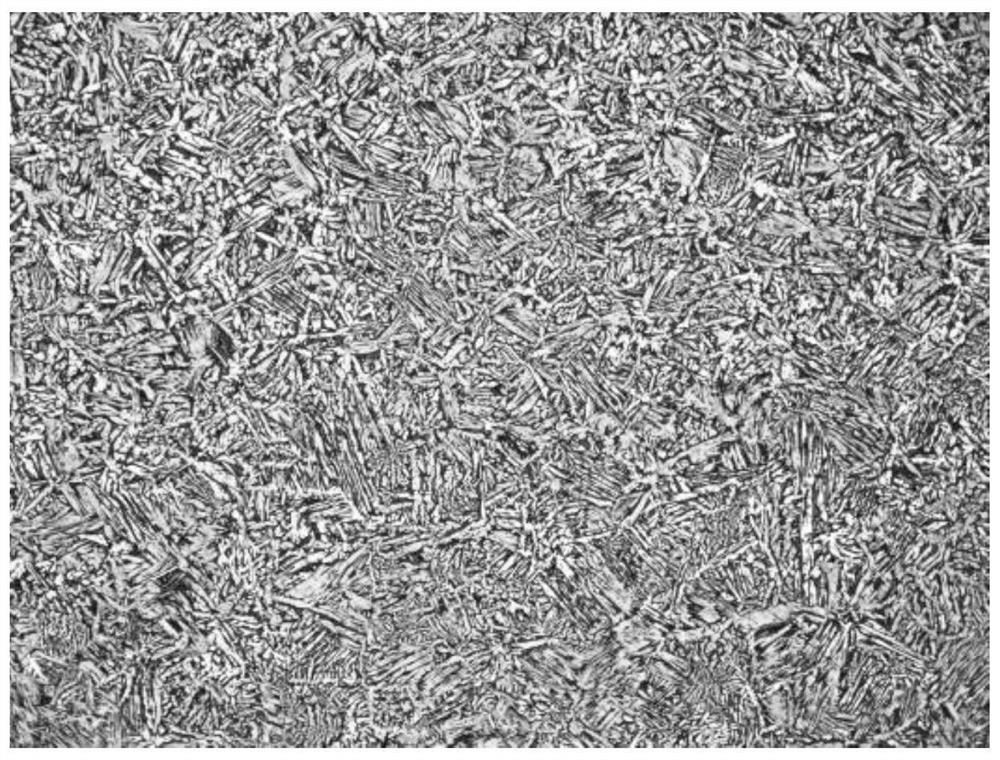

[0041] Such as figure 1 Shown is the first preferred embodiment of the present invention.

[0042] The modifier of the waste miscellaneous brass of this embodiment is configured according to the Si of 45% content, the Al-Ca alloy of 30% content, the Al-B alloy of 25% content, three kinds of raw materials are uniformly mixed together, and use copper The leather bag is ready for spare.

[0043] The method for producing the brass alloy using the above-mentioned modifying agent comprises the following steps in turn:

[0044] 1) Sorting and removing impurities from the collected waste miscellaneous copper mixture, briquetting the processed waste miscellaneous copper mixture, and evenly dividing it into three parts;

[0045] 2) Smelting: Smelting is carried out in the smelting furnace, and the smelting voltage V 0 When it is 800V, smelt the wire drawing copper powder until it is completely melted into copper water;

[0046] 3) Add the first part of the scrap copper mixture briqu...

Embodiment 2

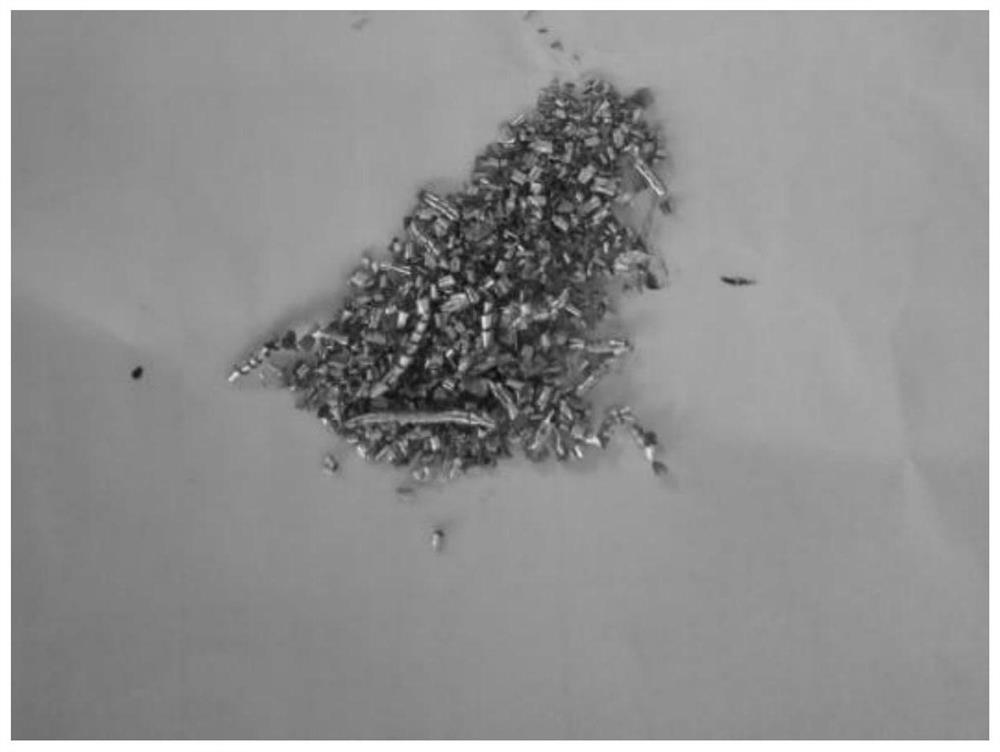

[0053] Such as image 3 with Figure 4 Shown is the second preferred embodiment of the present invention. The second embodiment adopts the same method for producing brass alloy as the first embodiment above, and the only difference from the first embodiment is that the modifying agent for scrap copper is different.

[0054] The modifying agent of the waste miscellaneous brass of present embodiment two is configured according to the Si of 50% content, the Al-Ca alloy of 25% content, the Al-B alloy of 25% content, three kinds of raw materials are uniformly mixed together, and use The copper wrap is ready for use. C46500 brand brass alloy was prepared by this modifier.

[0055] Such as image 3 with Figure 4 As shown, the prepared brass alloy material mainly uses α phase + β phase as the matrix phase, and there is a second phase that optimizes the machinability of the material at the same time, and the second phase is evenly distributed in the grain boundaries and crystals;...

Embodiment 3

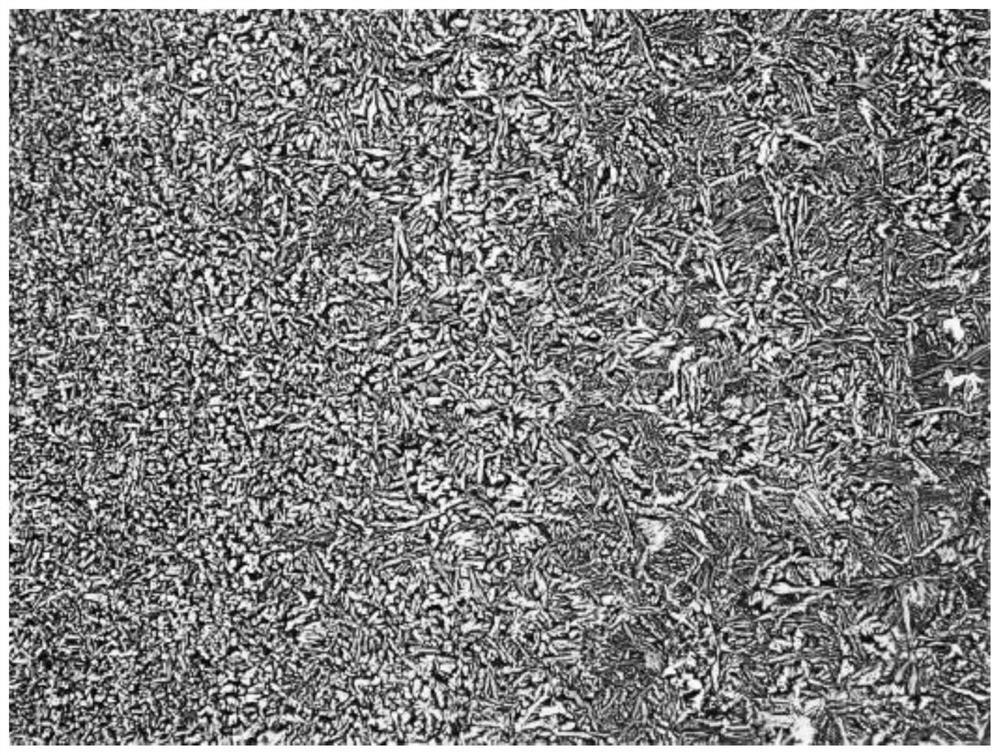

[0057] Such as Figure 5 with Image 6 Shown is the third preferred embodiment of the present invention. The third embodiment adopts the same method for producing brass alloy as the first embodiment above, and the only difference from the first embodiment is that the modifying agent for scrap copper is different.

[0058] The modifying agent of the waste miscellaneous brass of present embodiment three is configured according to the Si of 50% content, the Al-Ca alloy of 30% content, the Al-B alloy of 20% content, three kinds of raw materials are uniformly mixed together, and use The copper wrap is ready for use. The C46500 brand brass alloy was prepared by this modifier.

[0059] Such as Figure 5 with Image 6 As shown, the prepared brass alloy material mainly uses α phase + β phase as the matrix phase, and there is a second phase that optimizes the machinability of the material at the same time, and the second phase is evenly distributed in the grain boundaries and cryst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com