Chemical laboratory waste gas treating method and chemical laboratory waste gas treating device

A chemical laboratory and waste gas treatment technology, applied in chemical instruments and methods, separation methods, dispersed particle separation, etc., can solve problems such as failure to meet emission standards, damage to the life and health of employees and local people, and failure to meet the requirements of national development. , to achieve the effect of high absorption capacity, high solubility, and zero excessive discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

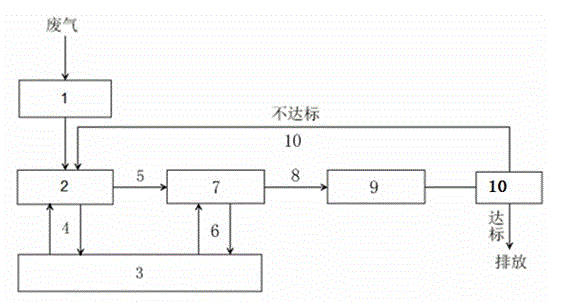

[0015] Such as figure 1 Shown: The exhaust gas produced in the chemical laboratory passes through the fume hood 1 with a sponge inside, and the dust contained in the exhaust gas is removed through the adsorption of the sponge; the gas after dust removal by the sponge is introduced into the first-level lye countercurrent spray tower 2 In the process, through the circulation pump 4, the NaOH solution with a mass concentration of 10% in the lye storage tank 3 is sprayed from the top of the primary lye countercurrent spray tower 2 (the amount of NaOH added in stages to ensure a mass concentration of 10%), to remove large amounts of Part of the acidic gas and soluble alkaline neutral gas; the residual gas is introduced into the secondary lye countercurrent spray tower 7 through the blower fan 5, and the residual gas is removed by the same treatment method as the primary lye countercurrent spray tower 2. more soluble gas; the remaining gas is introduced into the high-efficiency acti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com