Catalytic cracking flue gas desulfurization and dust removal process and desulfurization and dust removal device

A catalytic cracking and dedusting device technology, applied in combination devices, chemical instruments and methods, using liquid separating agents, etc., can solve the problems of high price, large temperature fluctuations, affecting the safe operation of the main oil refining device, etc., and achieve the effect of reliable operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] Preferred embodiments of the present invention are described in detail as follows:

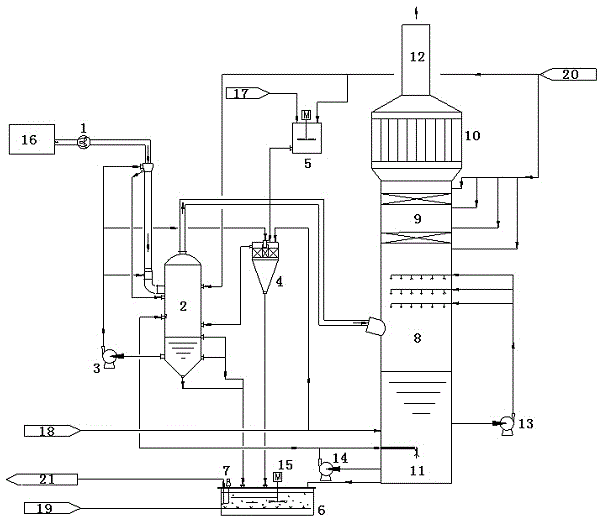

[0038] In this example, see figure 1 , a device for implementing catalytic cracking flue gas desulfurization and dedusting processes, including a booster fan 1 and a straight exhaust chimney 12, and also includes a flue gas dedusting and initial desulfurization system, a flue gas desulfurization system and a flue gas removal aerosol system, the flue gas The gas dedusting and initial desulfurization system is mainly composed of power wave scrubber 2, power wave washing circulation pump 3, inclined tube settler 4, flocculant tank 5, desulfurization waste liquid tank 6, agitator 15, desulfurization product delivery pump 7 and oxidation exposure The flue gas desulfurization system is mainly composed of an absorption tower 8, an absorption circulation pump 13, a mechanical demister 9, and a stirring device. The pipelines of the dynamic wave scrubber 2, the absorption tower 8, the mechanical...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com