A novel overflow sieve tray column with curved sieve tray

A sieve plate tower and overflow type technology, which is applied in the field of sieve plate tower, can solve the problems of unfavorable gas and liquid full contact, liquid is easy to block the sieve holes, and the gas output is small, so as to achieve enhanced pressure and increased contact volume , the effect of uniform contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

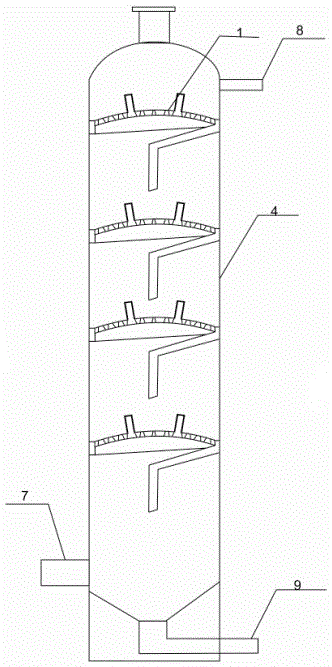

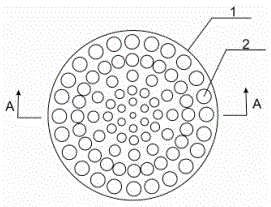

[0026] Install the sieve plate layer by layer in the sieve plate tower. The sieve plate adopts a circular arc panel with a high center and a low surrounding area. There are round holes or oval holes on the sieve plate. Multiple sieve holes are evenly arranged on the sieve plate. On the top, it gradually becomes larger from the middle of the sieve plate to the surroundings. There are also multiple hollow columns on the sieve plate. The multiple hollow columns form a circle on the sieve plate. There is a gap between the columns to prevent the flow of liquid. Flow, there are multiple sieves on the top of the side of the column, the gas contacts the liquid from a horizontal angle, and passes through the gaseous gas to be rectified into the tower, the gas is discharged from the tower through the sieves, and passes through the reboiler and condenser to achieve In the saturated state, the reflux liquid enters the tower through the liquid inlet pipe, contacts and mixes with the gas thr...

Embodiment 2

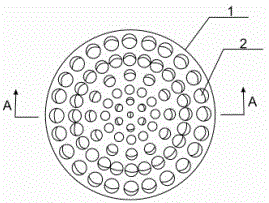

[0028] Install the sieve plate layer by layer in the sieve plate tower. The sieve plate adopts a circular arc panel with a high center and a low surrounding area. There are round holes or oval holes on the sieve plate. Multiple sieve holes are evenly arranged on the sieve plate. On the top, it gradually becomes larger from the middle of the sieve plate to the surroundings. There are also multiple hollow columns on the sieve plate. The multiple hollow columns form a circle on the sieve plate. There is a gap between the columns to prevent the flow of liquid. Flow, there are multiple screen holes on the top of the side of the column, the gas is in contact with the liquid from a horizontal angle, and there is a shielding arc plate on the screen hole, which is an outwardly convex arc surface, covering part of the screen hole , the mouth between the shielding arc plate and the sieve hole is aligned with the center of the sieve plate, and the gaseous gas to be rectified passes through...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com