Feeding method of recovery tower in dry-process continuous polymerization production technique of polyurethane

A technology of production process and feeding method, applied in the field of polymerization process, can solve the problems of high DMAC conductivity and acid value, large batch index difference, increased number of hazardous wastes, etc., achieve stable DMAC index, avoid index difference, reduce The effect of the number and quantity of hazardous waste discharges

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

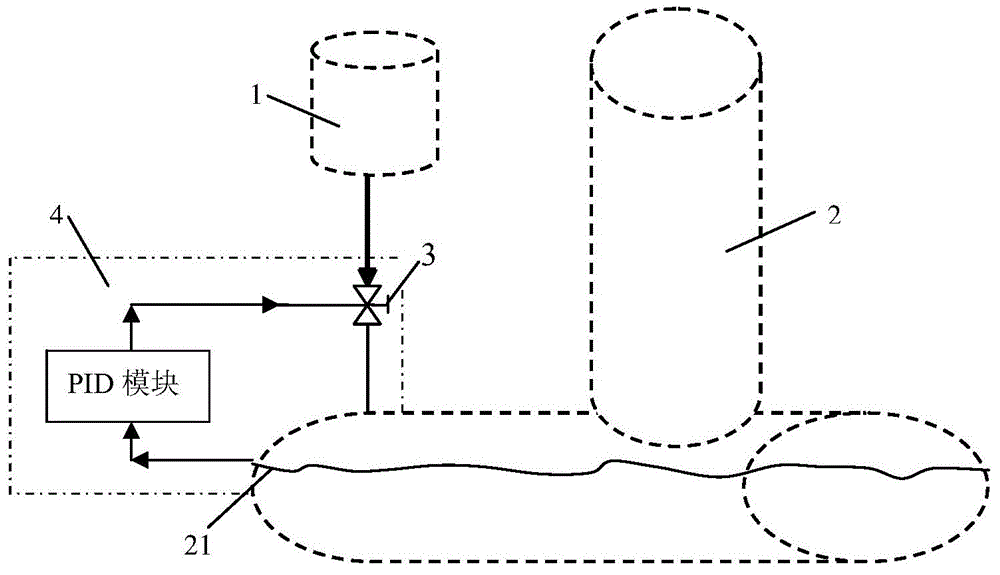

[0020] like figure 1 Shown, the recovery tower feed method in the spandex dry continuous polymerization production process comprises the following steps:

[0021] Pneumatic regulating valve 3 is set on the connecting pipeline of feed tank (T6301 tank) 1 and recovery tower (tower three) 2;

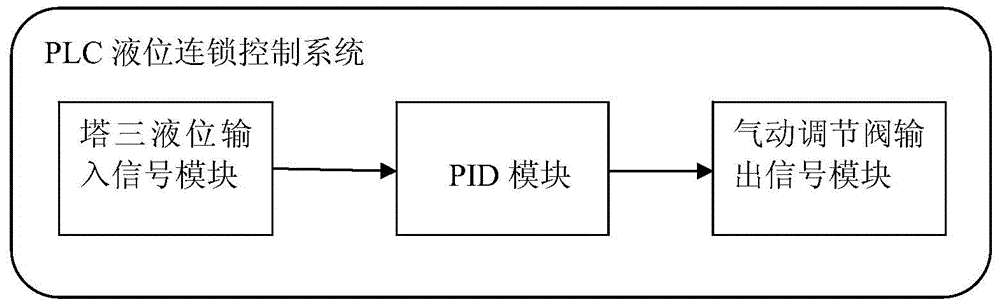

[0022] Add PLC liquid level chain control device 4 between the liquid level 21 of pneumatic control valve 3 and recovery tower 2; figure 2 As shown, the PLC liquid level chain control device 4 includes a liquid level input signal module, a PID module, and a pneumatic regulating valve output signal module;

[0023] The PLC liquid level interlocking control device 4 interlocks the liquid level 21 of the recovery tower 2 with the pneumatic control valve 3 , and the pneumatic control valve 3 is controlled according to the height line of the liquid level 21 of the recovery tower 2 . Intelligent adjustment ensures that the liquid level 21 of the recovery tower 2 maintains a constant value.

...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap