Constant-temperature cold compress bag

A technology of constant temperature and cold compress, which is applied in the direction of cooling appliances for treatment, heating appliances for treatment, contraceptives, etc. It can solve the problems of environmental and human wound pollution, poor cold compress effect, and secondary injury to the human body, etc., to achieve Effect of extending cold compress time, enhancing fit and cold compress effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

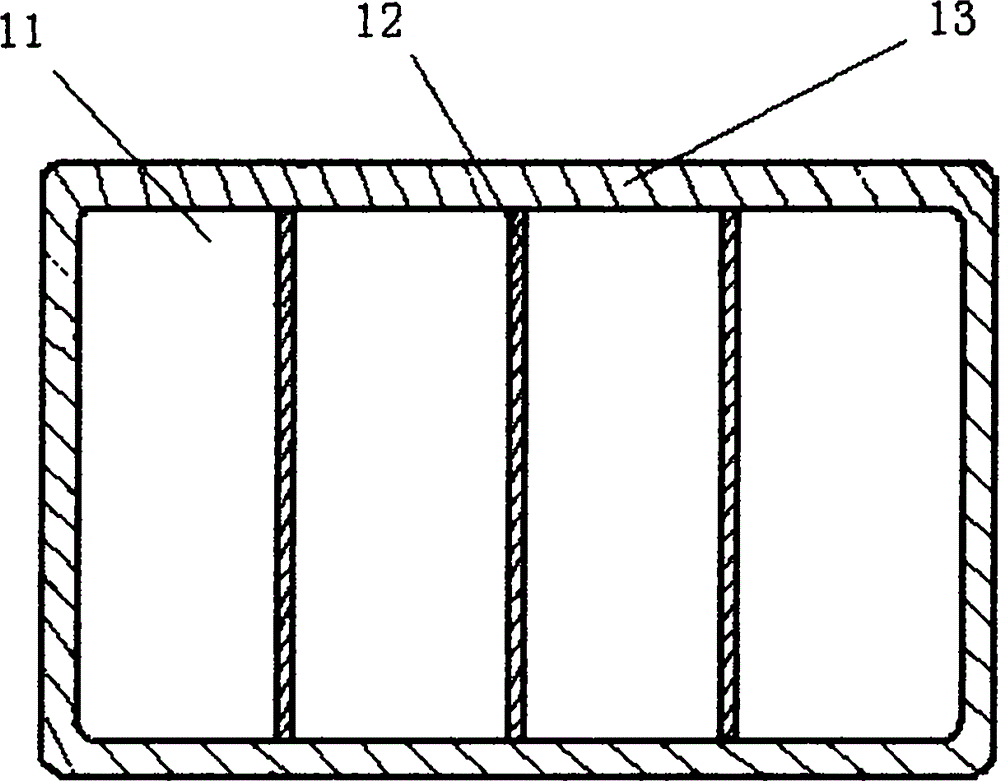

[0016] Such as figure 1 The rectangular cold compress bag shown has a size of 200mm×300mm, and the packaging film material is a 7-layer co-extruded composite film with a structure of PA / TIE / PE / TIE / PA / TIE / PE, a film thickness of 0.11mm, and a heat-sealed edge of 13 The width is 8mm, the four corners of the rectangle are arc-shaped, the refrigerant inside is paraffin, and the phase transition temperature is 2°C. The heat absorption of the paraffin is 240KJ / Kg, and the total mass of the cold pack is 200g. The rectangular cold compress bag 1 is isolated into four small cold compress bags 11, and the isolation strip 12 with a width of 2mm is closed between the small cold compress bags. The cold pack is divided into four connected small cold packs, which can be bent according to the shape of the target location (such as the calf) to increase the fit performance of the cold pack, and the cold pack is closed into connected small cold packs, reducing the relative After changing the f...

Embodiment 2

[0019] The cold compress bag described in Example 1 has a size of 200mm×70mm, and the built-in refrigerant is paraffin, the phase transition temperature is 15°C, the heat absorption is 230KJ / Kg, and the total mass of the cold compress bag is 100g.

[0020] This cold compress bag can be used for cooling and cold compressing the forehead, arms and other parts. When cold compressing, place the cold compress bag on the target location and fix it with a moderate bandage.

Embodiment 3

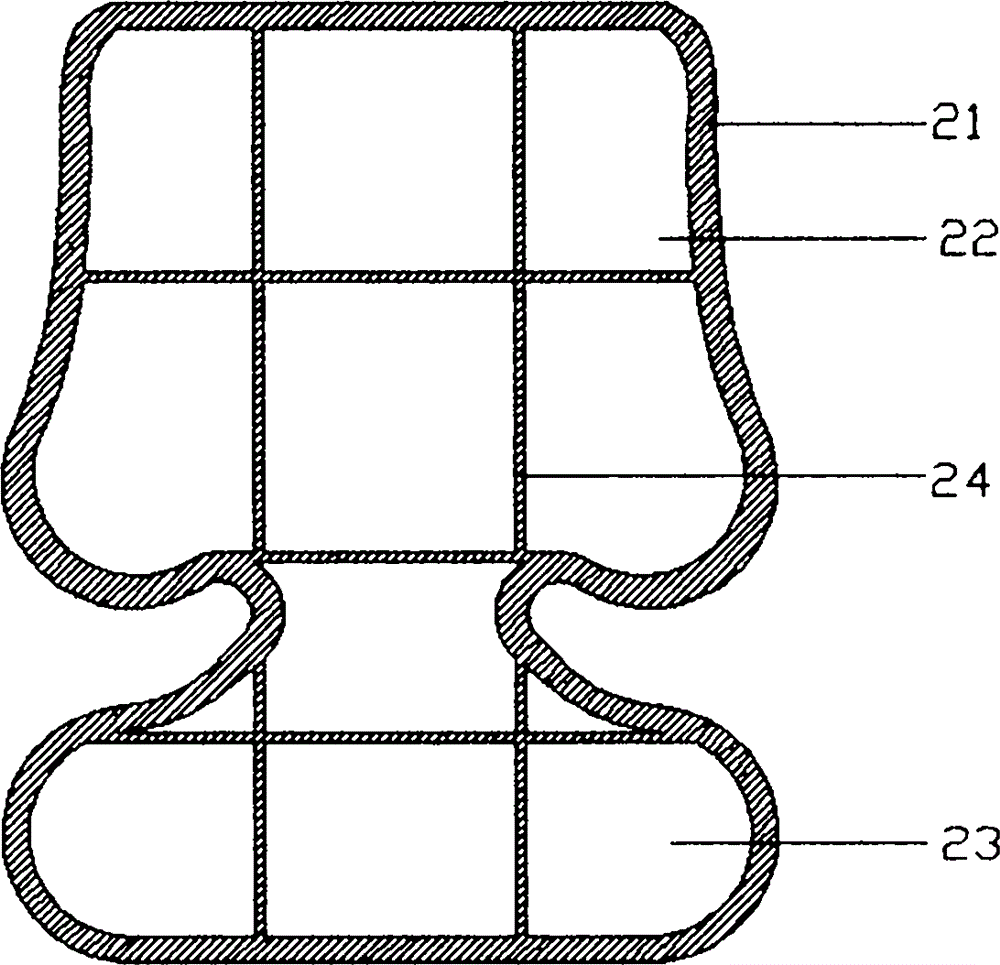

[0022] Such as figure 2 For the butterfly-shaped cold compress bag shown, the packaging film material is a 7-layer co-extruded composite film, its structure is PA / TIE / PE / TIE / PA / TIE / PE, the film thickness is 0.11mm, and the width of the sealing edge 21 of the cold compress bag is 8mm, the isolation strip 24 on the cold compress bag divides it into connected small cold compress bags, and the isolation strip 24 has a width of 2mm, which is convenient for adjusting the shape and fitting the cold compress position during cold compress. The overall length of the cold compress bag is 290mm, and the width is 240mm. The front disc 23 has a transverse dimension of 240mm and a longitudinal dimension of 80mm. The farthest distance between the adjacent concave outer edges of the slices is 100mm, and the paraffin refrigerant is installed inside. The phase transition temperature is 6°C, the heat absorption can reach 260KJ / Kg, and the total mass of the cold compress bag is 240g. The active ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| phase transition temperature | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com