Manufacturing method of pig fermentation bed

A production method and technology of a fermentation bed, which is applied in the field of pig breeding, can solve the problems that the fermentation bed is easy to become a "dead bed", the microorganisms in the bottom layer are anoxic, and the fermentation bed is easy to harden, etc., so as to save concentrated feed, have strong applicability, and improve efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

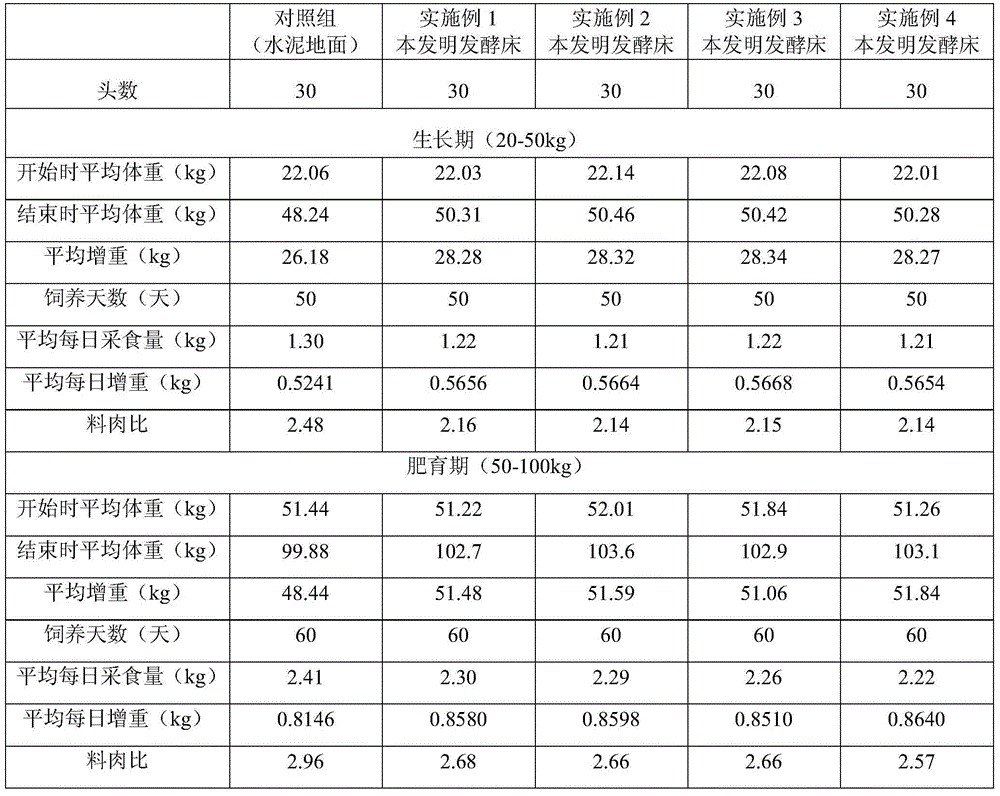

Examples

Embodiment 1

[0027] This implementation provides a kind of preparation method of pig fermentation bed, comprises the following steps:

[0028] Before making the fermentation bed, calculate the required amount of nutrient materials, fermentation bed strains, fermentation bed main materials and coarse salt according to different seasons, the size of the pig house, and the required thickness of the litter.

[0029] 1) Mixing the nutrient material and the strains of the fermentation bed with water evenly to obtain a mixture, the water content of which is 30%;

[0030] 2) Pile up the mixture stirred in step 1, and cover it tightly with plastic cloth for anaerobic fermentation; keep the room temperature at 20°C to 25°C, and in summer for 2 to 3 days, the fermented raw materials will emit a sweet and sour koji aroma and then ferment success;

[0031] 3) Mix and stir the material obtained in step 2, the main material of the fermentation bed, and coarse salt evenly, add water during the stirring p...

Embodiment 2

[0040] This implementation provides a kind of preparation method of pig fermentation bed, comprises the following steps:

[0041]Before making the fermentation bed, calculate the required amount of nutrient materials, fermentation bed strains, fermentation bed main materials and coarse salt according to different seasons, the size of the pig house, and the required thickness of the litter.

[0042] 1) mixing the nutrient material and the strains of the fermentation bed with water evenly to obtain a mixture, the water content of which is 25%;

[0043] 2) Pile up the mixture stirred in step 1, and cover it tightly with plastic cloth to carry out anaerobic fermentation; keep the room temperature at 20°C to 25°C, and for 3 days in summer, the fermented raw materials emit a sweet and sour koji aroma, which means the fermentation is successful;

[0044] 3) Mix and stir the material obtained in step 2, the main material of the fermentation bed, and coarse salt evenly, add water durin...

Embodiment 3

[0052] This implementation provides a kind of preparation method of pig fermentation bed, comprises the following steps:

[0053] Before making the fermentation bed, calculate the required amount of nutrient materials, fermentation bed strains, fermentation bed main materials and coarse salt according to different seasons, the size of the pig house, and the required thickness of the litter.

[0054] 1) Mixing the nutrient material and the bacteria in the fermentation bed with water evenly to obtain a mixture, the water content of which is 35%;

[0055] 2) Pile up the mixture stirred in step 1, and cover it tightly with plastic cloth for anaerobic fermentation; keep the room temperature at 20°C-25°C for 7 days, and the fermented raw materials will emit a sweet and sour koji aroma, which means the fermentation is successful;

[0056] 3) Mix and stir the material obtained in step 2, the main material of the fermentation bed, and coarse salt evenly, add water during the stirring p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com