Intelligent fine soil preparation device

A fine soil preparation and intelligent technology, applied in the field of agricultural machinery, can solve the problems of high heat generation, poor soil flatness on the surface of the ridge, and the large size of the gearbox affecting the quality of the side of the ridge, so as to improve the efficiency of cutting crushed soil The effect of increasing the number of times, meeting the requirements of the soil preparation specification, and increasing the amount of oil

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

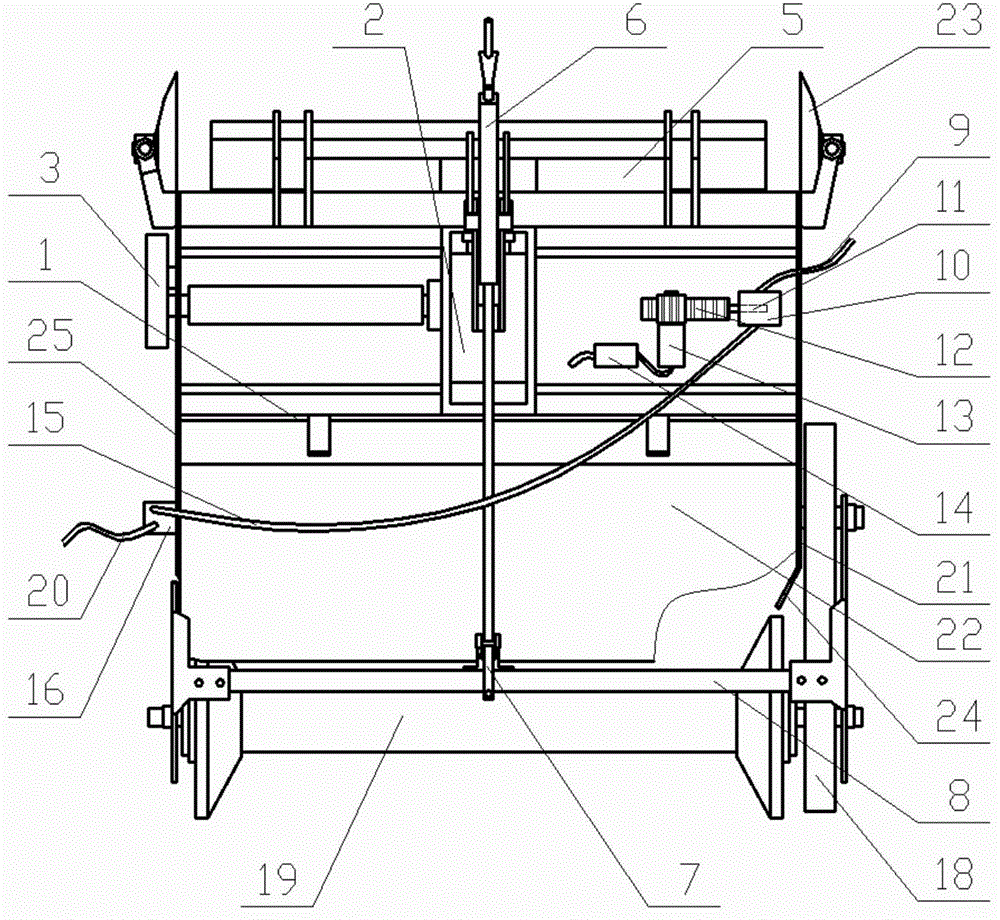

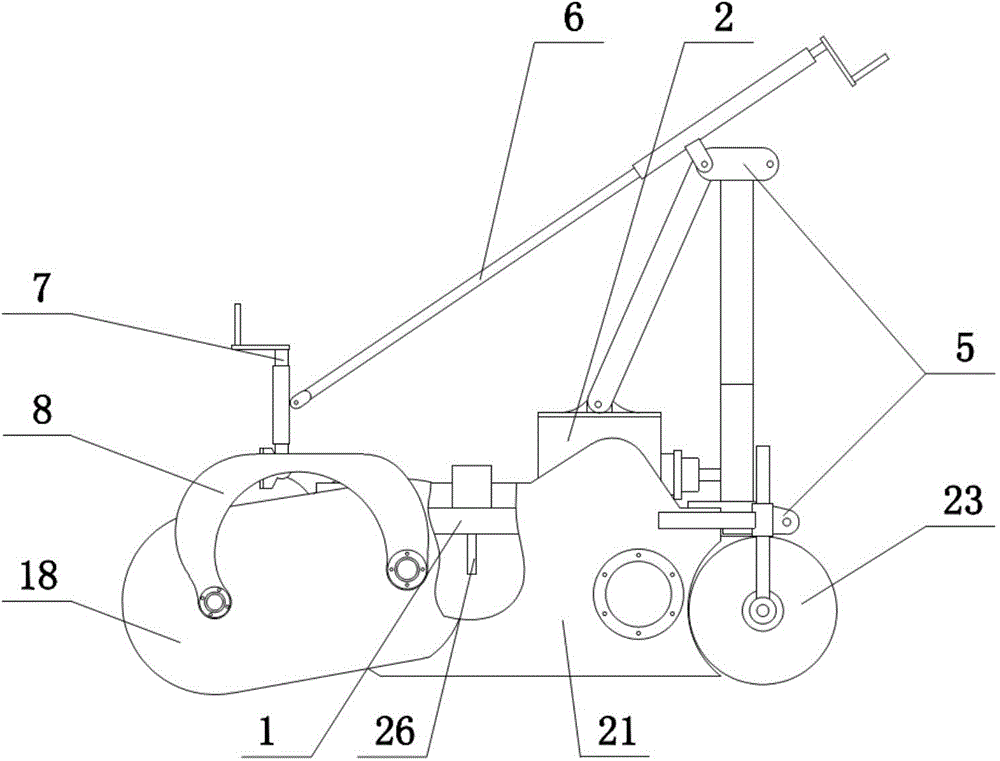

[0027] The intelligent fine land preparation device of this embodiment is as follows: figure 1 and figure 2 As shown, the front side of the frame 1 has a conventional three-point suspension support frame 5, which is used to be connected to a walking power device such as a tractor. Nut, the lower end of this long screw rod 6 is hinged with the short screw rod 7 to form the short nut of helical pair. The lower end of the short screw rod 7 is connected with a fork-shaped bilateral support frame 8 and is hinged with the frame 1 . Therefore, the height and inclination angle of the bilateral support frame 8 can be adjusted as required by manipulating the long screw rod and the short screw rod respectively. The front side of the frame 1 supports the deep plowing cutter roller assembly 4 , and the rear side supports the finishing cutter roller assembly 17 driven by the hydraulic motor 16 and the pressing wheel 19 .

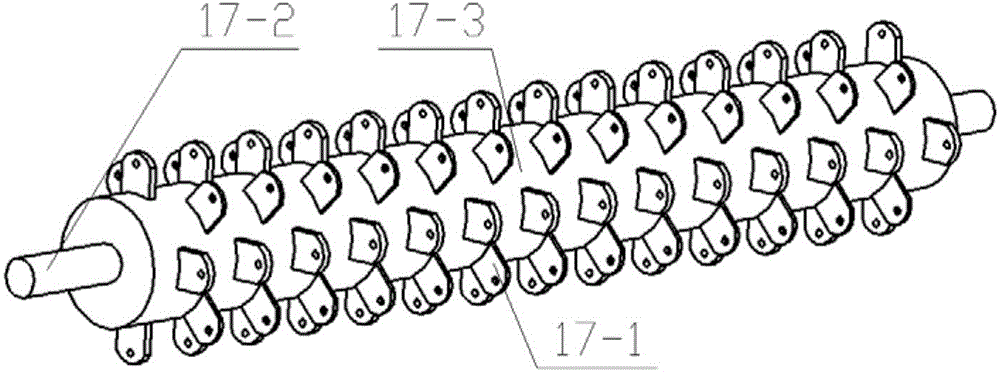

[0028] The structure of deep tillage knife roller assembly 4 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com