Slicing device with product holder

A gripper and slicing technology, applied in conveyors, metal processing, transportation and packaging, etc., can solve the problem of expensive gripper drive and achieve good height change effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

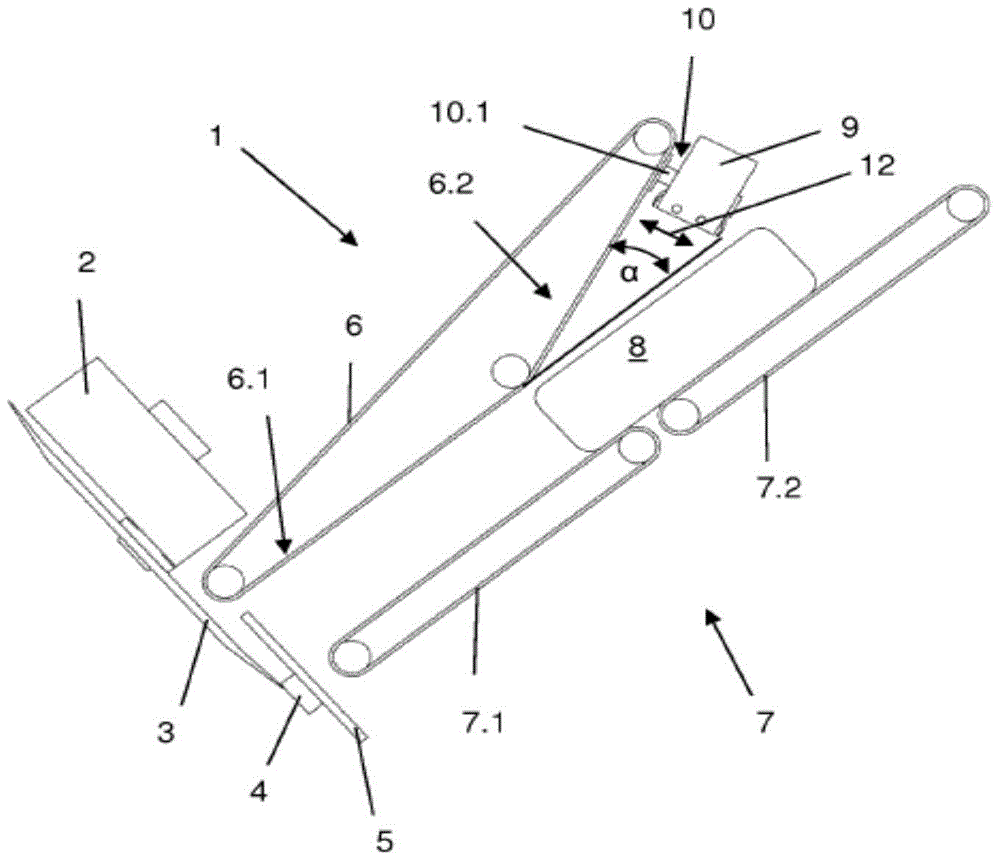

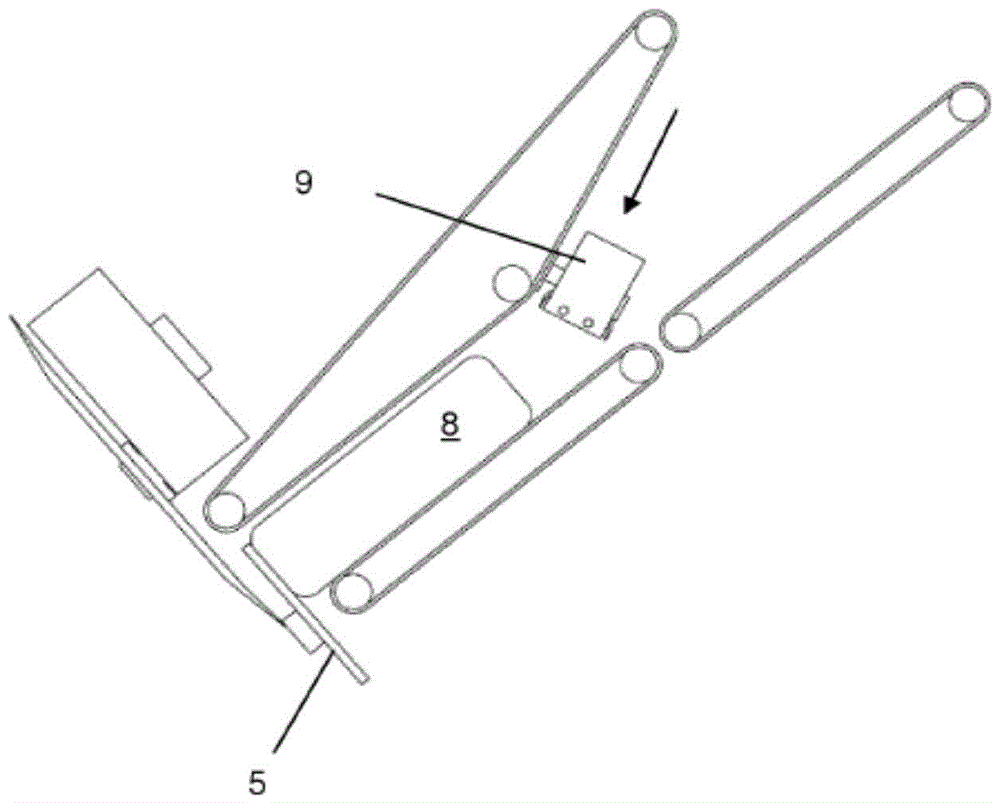

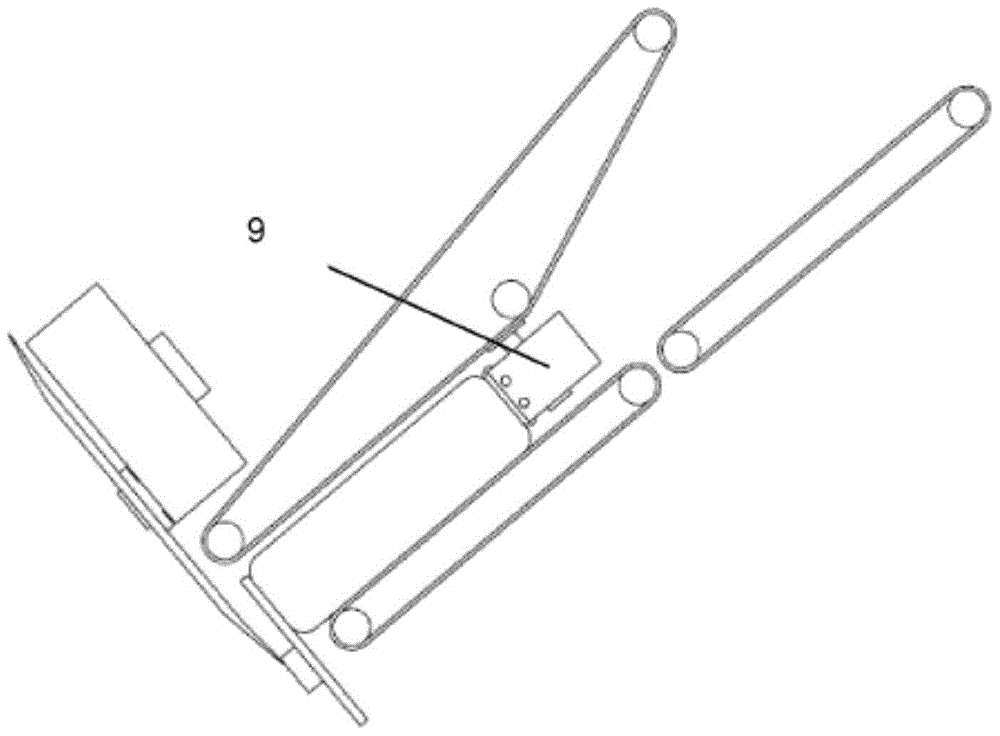

[0026] figure 1 A slicing device according to the invention is shown in which a food slab 8 is placed on a support 7 and transported in the direction of the rotating cutting blade 3 . The cutting blade, in the case of a circular blade, is arranged on a rotor 2, which drives the blade in rotation and at the same time rotates along a circular path, so that each rotation of the cutting blade around the circular path separates a slice from the food product and then The food product is released before the next slice is cut. The cut food slices then fall onto a transfer table (not shown). The thickness of the food slice corresponds to the feed of the food slab 8 between the two cuts. During cutting, the cutting blade 3 interacts with a cutting edge 4 preferably located on the front end of the support 7 . Furthermore, the cutting device of the invention comprises an upper device 6 , in this example an endless belt, preferably an endless traction belt, which presses the food produ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com