Multi-nozzle type gas burner

A gas burner and multi-nozzle technology, applied in the direction of burner, combustion method, combustion type, etc., can solve the problems of high maintenance cost, small pulse control control range, short service life, etc., and achieve simplification of overall structure and pipeline design , Operational reliability performance improvement, energy saving and environmental protection benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The following will further describe the multi-jet gas burner according to the present invention according to specific embodiments and accompanying drawings, but this description does not constitute an improper limitation of the present invention.

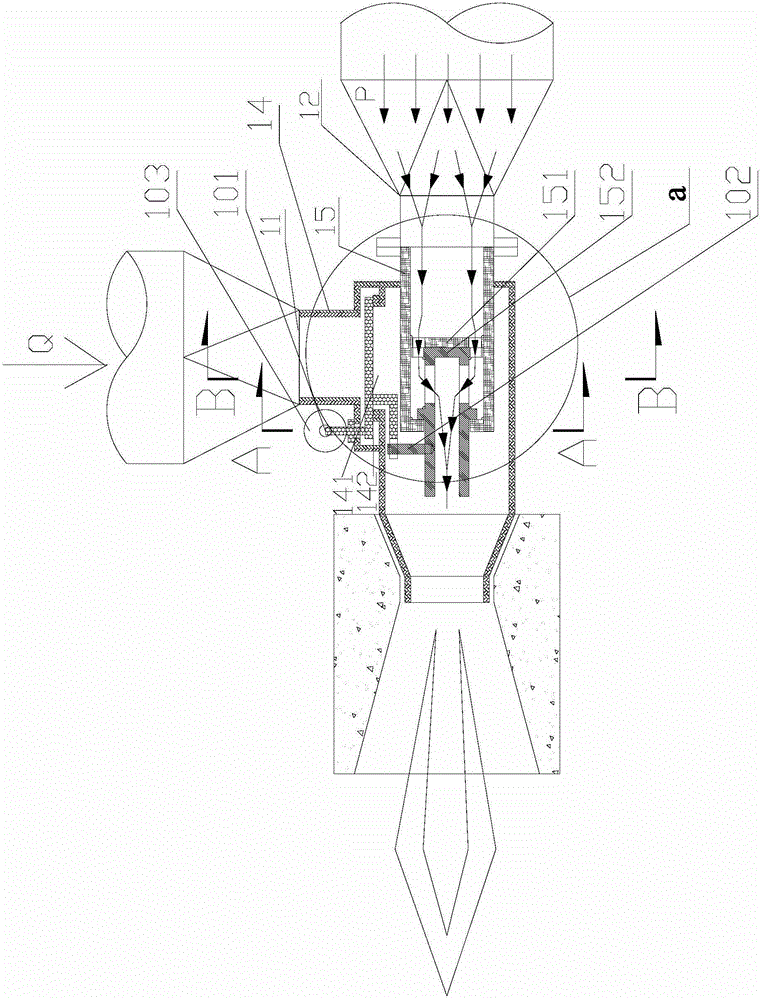

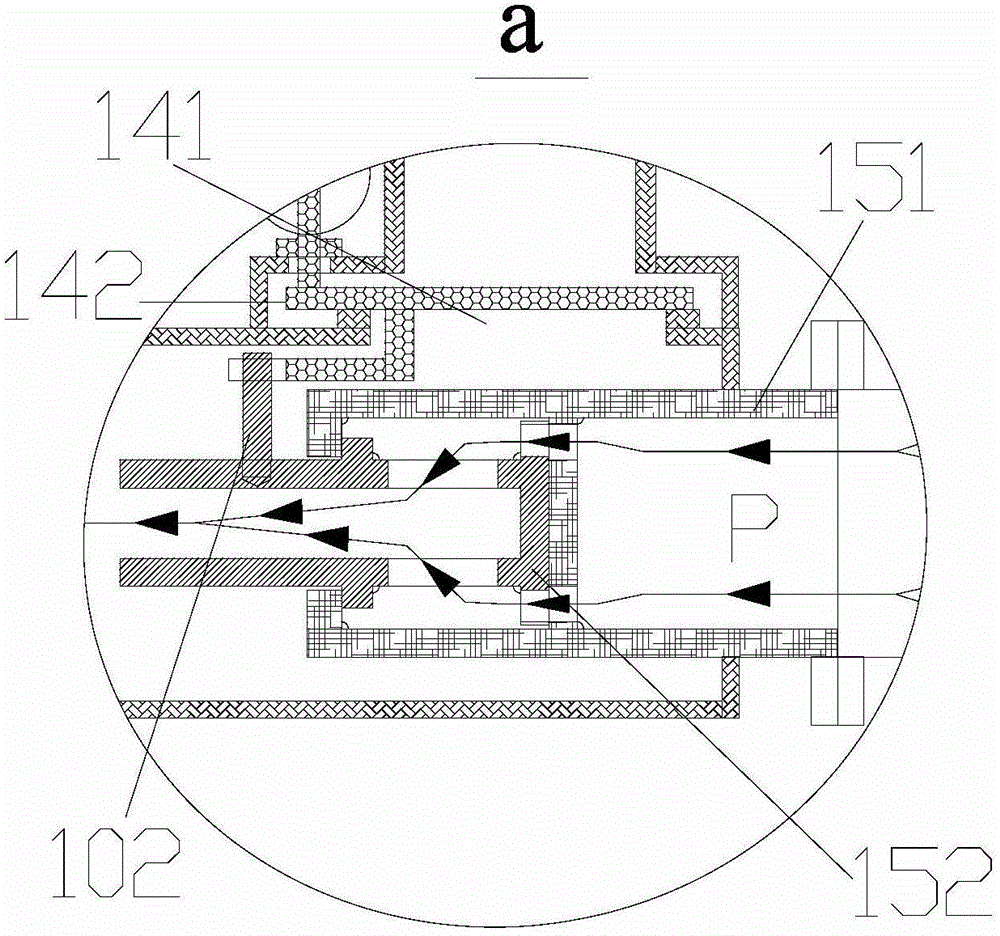

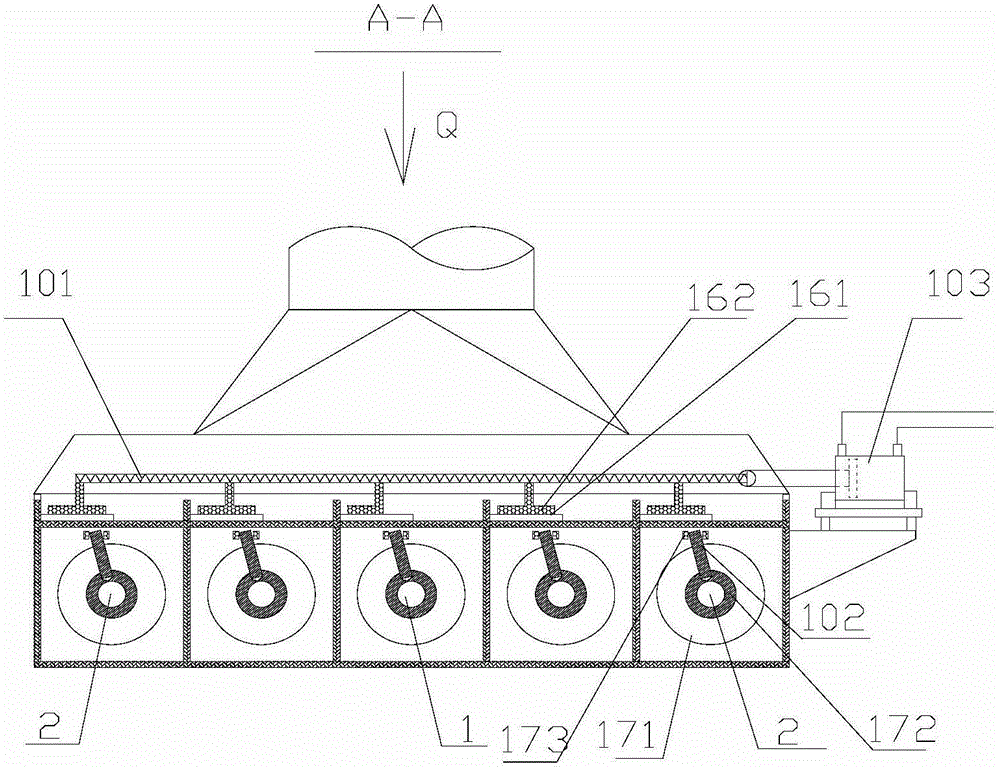

[0040] figure 1 It shows the structure of the multi-jet gas burner provided by the present invention in the state where the main jet is in the longitudinal section in this embodiment, figure 2 The structure of the main jet air valve and the main jet gas valve in the multi-nozzle gas burner is specifically shown.

[0041] In this embodiment, the multi-jet gas burner includes an air box, a gas box, a main nozzle and four auxiliary nozzles, the auxiliary nozzles are arranged around the main nozzle, and air is stored in the air box. 30% CO gas. Such as figure 1 and figure 2 As shown, an air inlet 11 is provided on the air box, and air enters into the air box through the air inlet 11, and a gas inlet 12 is provided on the ga...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com