Blade of a rotary flow machine with a radial strip seal

A technology of seals and blades, which is applied in the field of blades of swirl machines, can solve the problems of weakened cooling efficiency and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

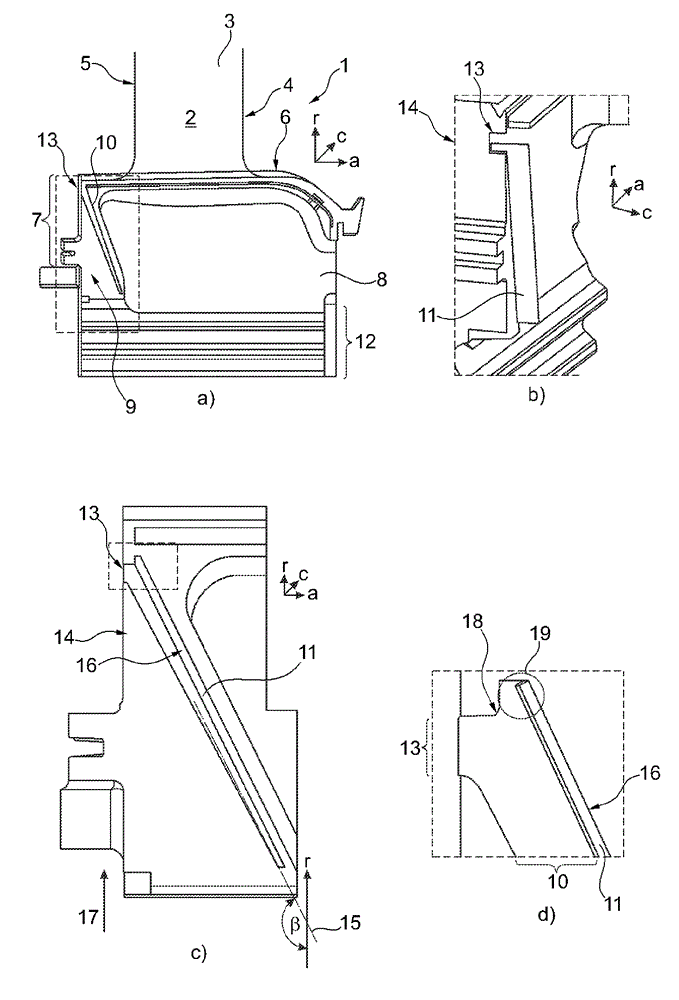

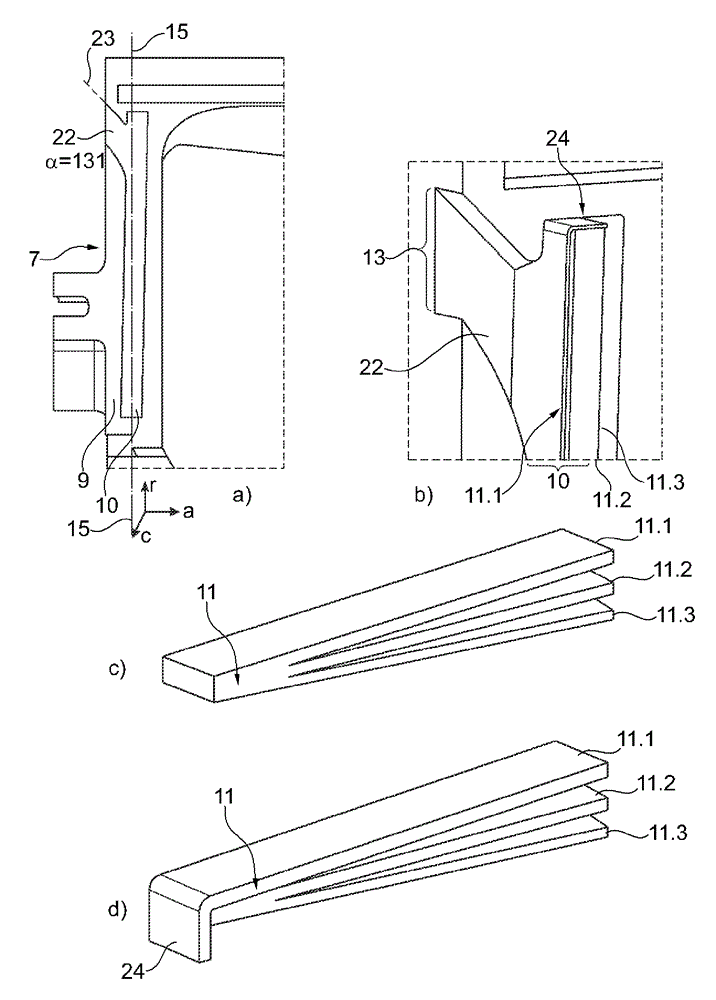

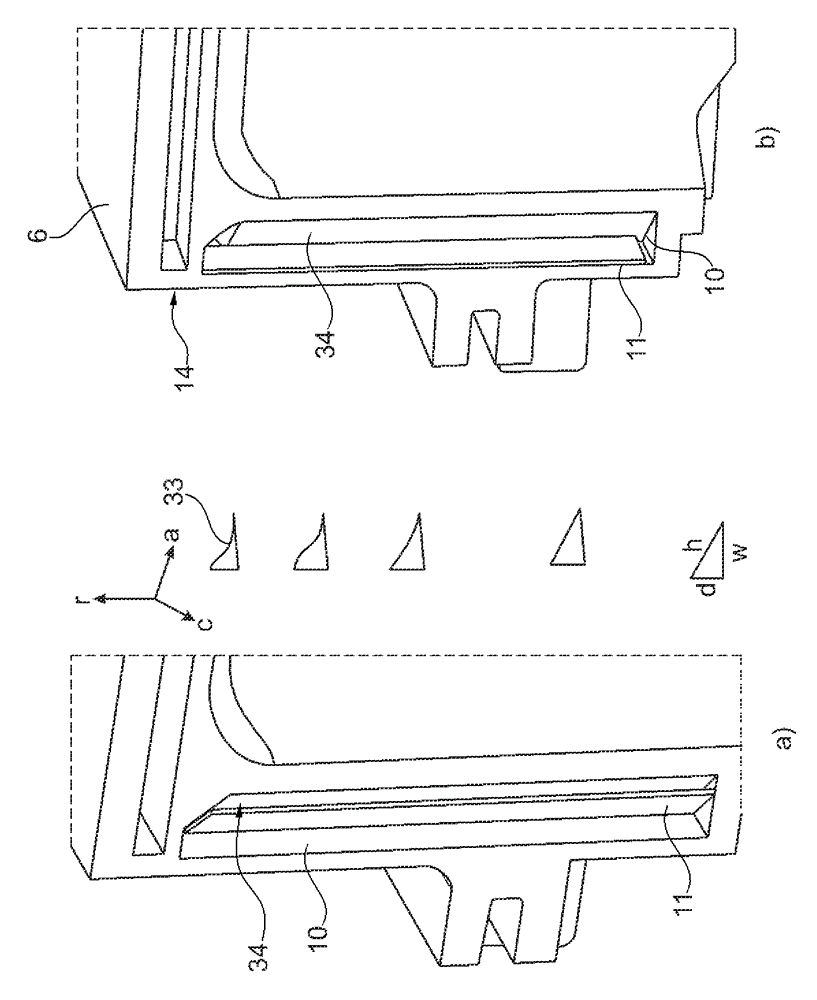

[0069] figure 1 A first embodiment of a blade 1 is illustrated, eg a moving low pressure turbine blade for a gas turbine arrangement. figure 1 a shows a side view in the circumferential direction c of a swirler (not shown) along a radially inner section of the blade 1 . figure 1 The axes shown in a mark the axial direction a, the radial direction r and the circumferential direction c of the swirl machine. Further description refers to the axes defined in the respective descriptions.

[0070] The blade 1 comprises an airfoil 2 having a suction surface 3 and a pressure surface (not shown) joined together along a leading edge 4 and a trailing edge 5 . The radially inwardly extending end of the airfoil 2 joins an inner platform 6 connecting the airfoil 2 to a shank 7 at the radial end of the airfoil 2 . The shank 7 has at least one tang socket 8 defined as a region recessed into the shank 7 which is parted by the axial a of the platform 6 and by at least one radially directed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com