Double ventilation masonry wall

A masonry wall and double-layer technology, which is applied in the field of building wall structure, can solve the problems of harmful gas discharge, gas leakage, combustion, combustion explosion, etc., and achieve the effect of free space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments to further understand the purpose, solution and effect of the present invention, but it is not intended to limit the scope of protection of the appended claims of the present invention.

[0039] The double-layer ventilated masonry wall of the present invention is mainly suitable for the interior wall and exterior wall of industrial buildings, and is beneficial to solve the ventilation problem that cannot be solved by conventional methods.

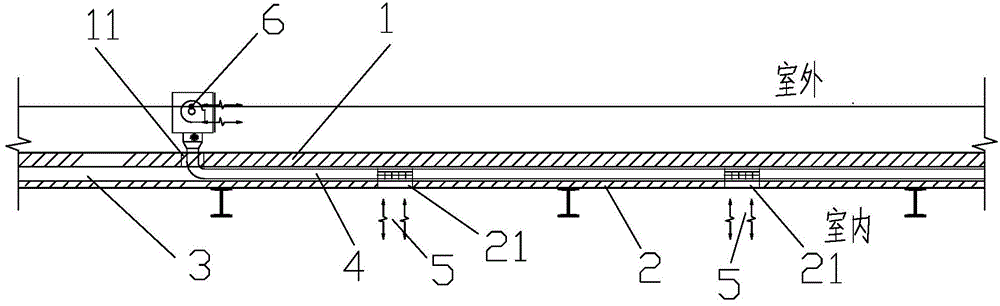

[0040] refer to figure 1 and figure 2 , which is a structural diagram of a double-layer ventilated masonry wall according to the first embodiment of the present invention. The double-layer ventilated masonry wall of this embodiment is used for the exterior walls of industrial buildings, and its main purpose is to discharge indoor dirty air to the outside, including The first wall b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com