Air-circulation dust remover

A technology of dust removal device and circulating air, which is applied in the direction of dust removal, separation of dispersed particles, cleaning methods and appliances, etc., which can solve the problems of many pipelines, high operating costs, and low dust removal efficiency, so as to reduce the circulating air volume and reduce the circulating air volume , Improve the effect of dust removal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

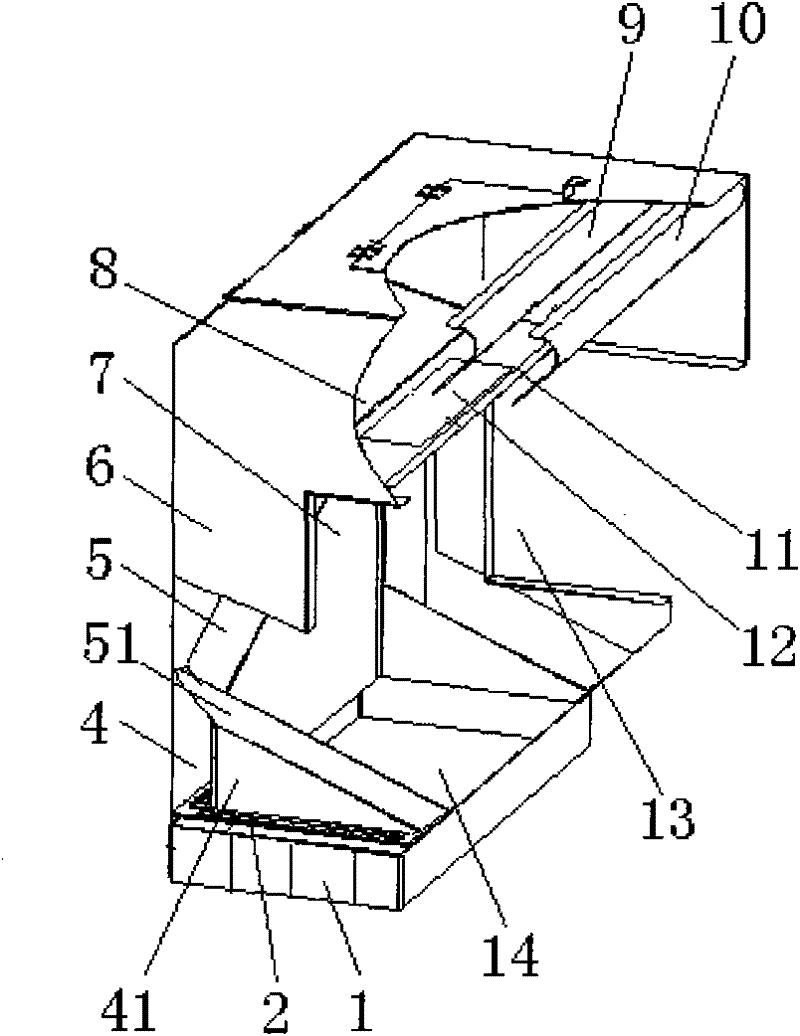

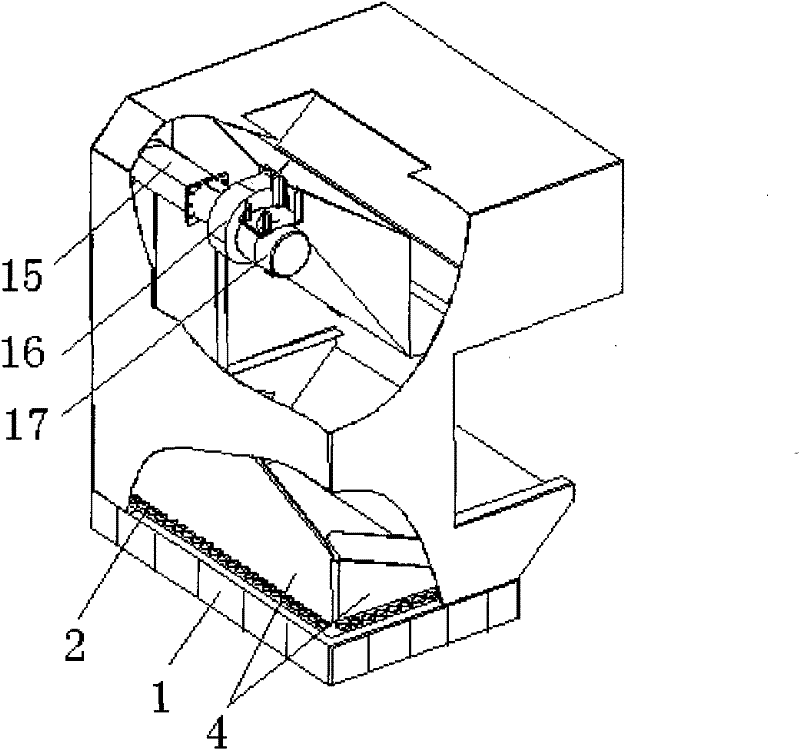

[0018] The present invention will be further described below in conjunction with the accompanying drawings.

[0019] The circulating air dust removal device provided in this embodiment is installed between two end-to-end conveyors with a height difference to remove dust caused by the height difference.

[0020] The circulating air dedusting device comprises a cover body 7 with a feed port 13 and a discharge port 14 on it, wherein the feed port 13 on the cover body 7 is located on the right side of the cover body 7, and is connected with the high conveyor 20 The discharge end of the discharge port is connected, and the discharge port 14 is located at the bottom surface of the cover body 7, and is connected with the feed end of the low conveyor 21, such as Figure 5 , the periphery of the outlet 14 of the cover body 7 is provided with an orifice 2, and the orifice 2 is horizontally arranged along the left, rear, and right three-quarters of the periphery of the outlet 14, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com