Artificial leather with characteristics of anti-slipping, impact resistance, and strong air permeability sweat releasing

An artificial leather and impact-resistant technology, applied in the field of artificial leather, can solve the problems of weak fabric, easy cracking, low friction coefficient of smooth surface, etc., to achieve the effect of strong and durable base material, increased anti-skid ability, and enhanced friction coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

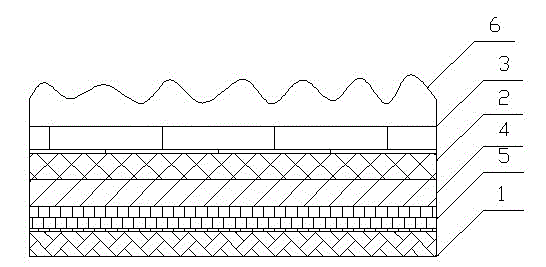

[0016] see figure 1 , the present invention relates to a non-slip, impact-resistant, breathable and sweat-wicking strong artificial leather, comprising a base material 1, a first foam layer 2 and a dense surface layer 3, based on the state of use, the first foam layer 2 is fixedly attached to the dense surface layer The inner surface of layer 3, the substrate 1 is located on the side of the first foam layer 2 facing away from the surface dense layer 3, and the second foam layer 4 and The impact-resistant layer 5 is provided with a plastic film layer 6 on the outer surface of the surface dense layer 3, the plastic film layer 6 is a PVC plastic layer with a concave-convex surface, and the second foam layer 4 is located at the first foam layer 2 On one side, the impact-resistant layer 5 is located on one side of the substrate 1 .

[0017] The base material is made of a fabric, and the fabric is interwoven with warp threads and weft threads, the warp threads and weft threads are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com