Novel fastening connection method and device for sacrificial anode assembly

A sacrificial anode and fastening connection technology, which is applied in the field of sacrificial anode assembly technology, can solve the problems of falling off, loose connection shaft, shortened life of water heater, etc., and achieve the effect of uniform fastening deformation, uniform deformation and firm connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

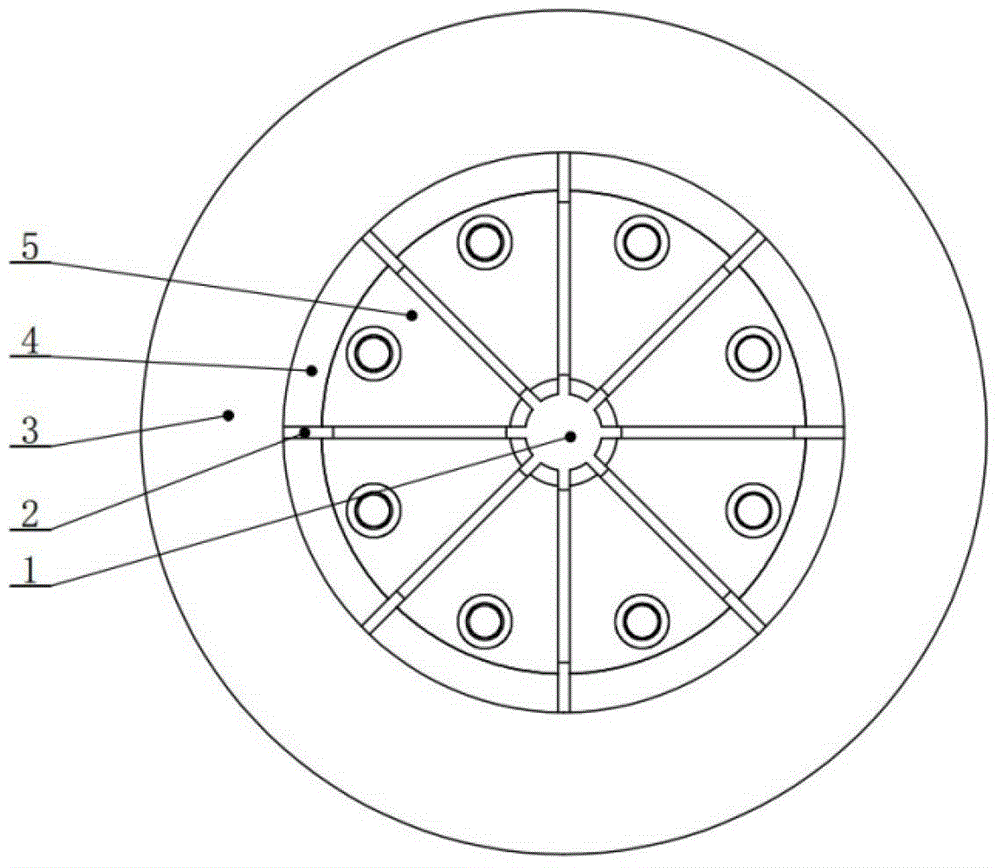

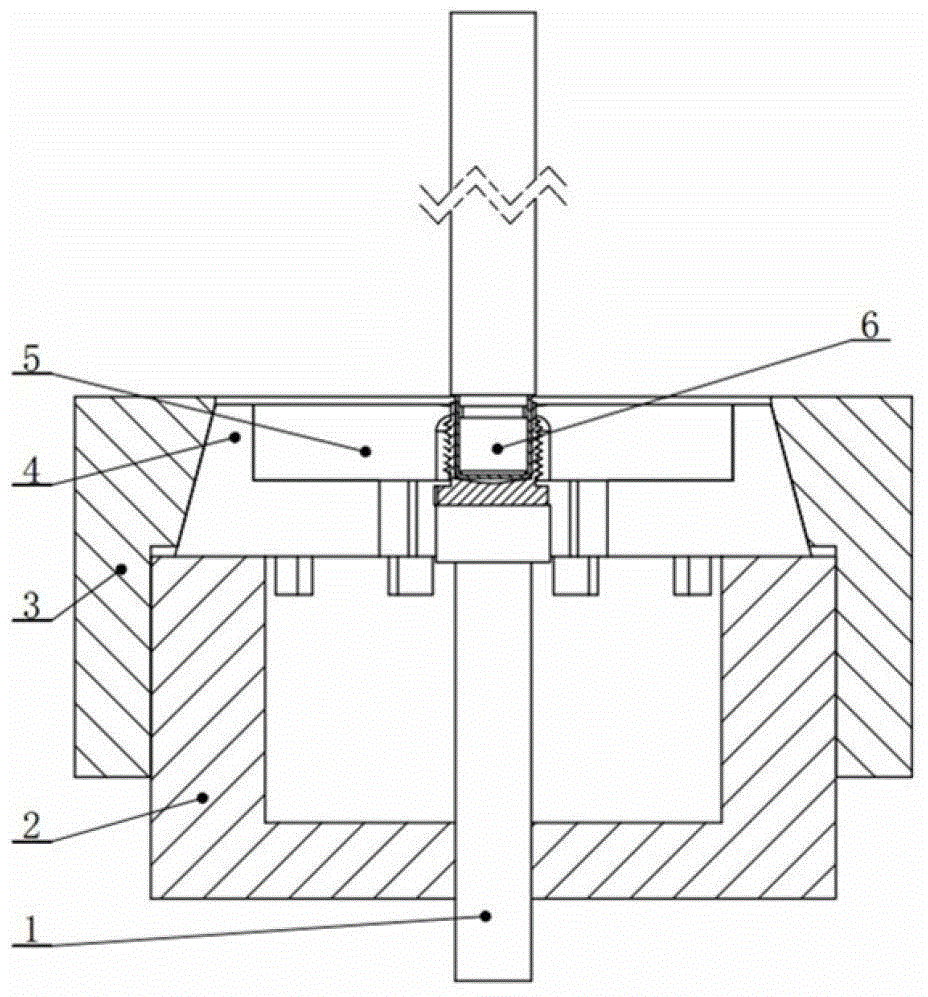

[0034] Such as Figure 3-1 with Figure 3-2 Shown is an embodiment of the fastening and connection method of the present invention. The sacrificial anode 6 to be assembled includes an anode rod 6-3, a sealing buffer cap 6-2 and a nut 6-1. The device of the present invention is used for fastening connection.

[0035] 1. Install the mold 5 for the test piece with a diameter of 70mm, adjust the tightening pressure of the sliding sleeve 3 to 0.2MPa, adjust the upper stroke of the sliding sleeve 3 to 10mm, and the lower stroke to 0mm;

[0036] 2. Place the end of the nut 6-1 of the sacrificial anode 6 on the top of the positioning block 1, adjust the position of the positioning block 1 to 0mm, so that the crimping head of the mold 5 can be crimped to the unthreaded part of the nut 6-1 ;

[0037] 3. The sliding sleeve 3 starts to move up and down to make the mold sleeve 4 tighten or loosen in the radial direction, and drive the mold 5 to tighten or loosen in the radial direction to comple...

Embodiment 2

[0039] Such as Pic 4-1 with Figure 4-2 Shown here is another embodiment of the fastening and connection method of the present invention. The sacrificial anode 7 to be assembled includes an anode rod 7-2 and a connecting shaft 7-1, and the device of the present invention is used for fastening and connection.

[0040] 1. Install the mold 5 for the test piece with a diameter of 30mm, adjust the tightening pressure of the sliding sleeve 3 to 30MPa, adjust the upper stroke of the sliding sleeve 3 to 30mm, and the lower stroke to 0mm;

[0041] 2. Place the end of the connecting shaft 7-1 of the sacrificial anode 7 flat on the positioning block 1, adjust the position of the positioning block 1 to 50mm, so that the crimping head of the mold 5 is pressed on the connecting shaft 7-1, and the outer edge of the crimping head is away 1mm part of connecting shaft 7-1 port;

[0042] 3. The sliding sleeve 3 starts to move up and down to make the mold sleeve 4 tighten or loosen in the radial direct...

Embodiment 3

[0044] Such as Figure 5-1 with Figure 5-2 Shown here is another embodiment of the fastening connection method of the present invention. The sacrificial anode 8 to be assembled includes an anode rod 8-2 and a screw rod 8-1, and the device of the present invention is used for fastening connection.

[0045] 1. Install the mold 5 for the test piece with a diameter of 8mm, adjust the tightening pressure of the sliding sleeve 3 to 3MPa, adjust the upper stroke of the sliding sleeve 3 to 60mm, and the lower stroke to 0mm;

[0046] 2. Place the end connecting the sacrificial anode 8 and the screw 8-1 flat on the positioning block 1, adjust the position of the positioning block 1 to 400mm, so that the crimping head of the mold 5 is pressed on the anode rod 8-2, and the outer edge of the crimping head The part 3mm away from the 8-2 screw port of the anode rod;

[0047] 3. The sliding sleeve 3 starts to move up and down to make the mold sleeve 4 tighten or loosen in the radial direction, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com