Spherical graphite coating and preparation method thereof

A technology of graphite coating and ball type, applied in the direction of coating, etc., can solve problems such as aging and health hazards, and achieve the effects of good water resistance, lower temperature of electronic products, and simple coating method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

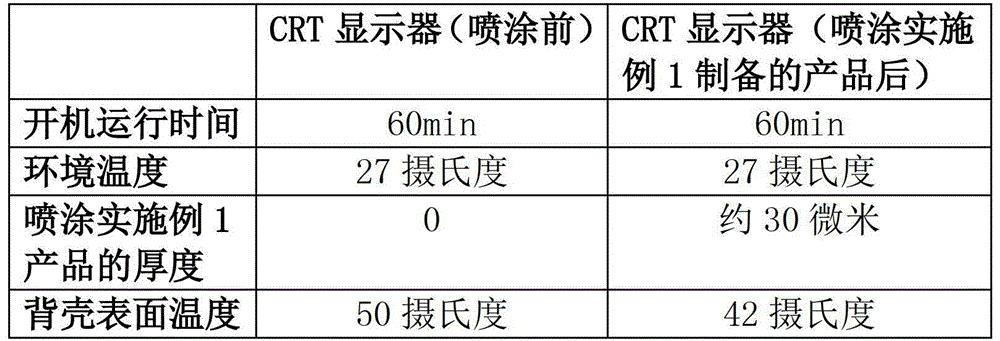

[0023] A kind of spherical graphite paint, its formula is composed as following table:

[0024]

[0025] Table 1 The composition of a spherical graphite material formula

[0026] Prepare spherical graphite coating with the formula of embodiment 1 as example, illustrate preparation method of the present invention:

[0027] Add 60 parts by mass of spherical graphite, 10 parts by mass of natural graphite, 0.2 parts by mass of SXP-107 silicone polyether composite defoamer and 1 part by mass of polydimethylsiloxane into the dispersion tank, and control the speed at 800-1000 rpm Add 2 parts by mass of cellulose ether into the dispersion tank, grind at high speed for 10-30min, then add 1 part by mass of 2,2,4-trimethyl-1,3-pentanediol monoiso Butyrate, 0.5 parts by mass of 1,2-propanediol and 57 parts by mass of water-based acrylic emulsion, stirring; finally add 0.7 parts by mass of benzimidazole methyl carbamate, 0.2 parts by mass of 1,2-benzoiso Thiazol-3-one and 0.3 parts by...

Embodiment 2

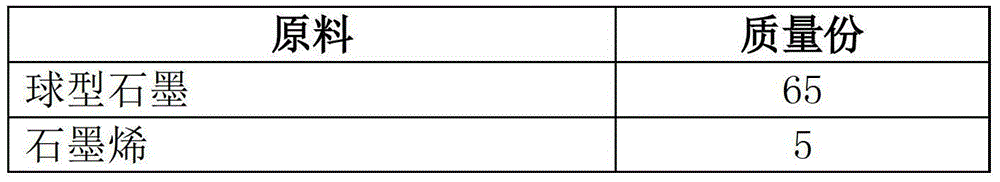

[0035] A kind of spherical graphite paint, its formula is composed as following table:

[0036]

[0037]

[0038] Table 4 A composition table of spherical graphite material formula

PUM

| Property | Measurement | Unit |

|---|---|---|

| Water resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com