Production system and production method of high-quality machine-made sand

A production system and technology of machine-made sand, applied in the field of machine-made sand production system, can solve the problems of unreasonable gradation, poor workability, and few fine particles, and achieve huge economic and social benefits, improve work performance, and round grain shape.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

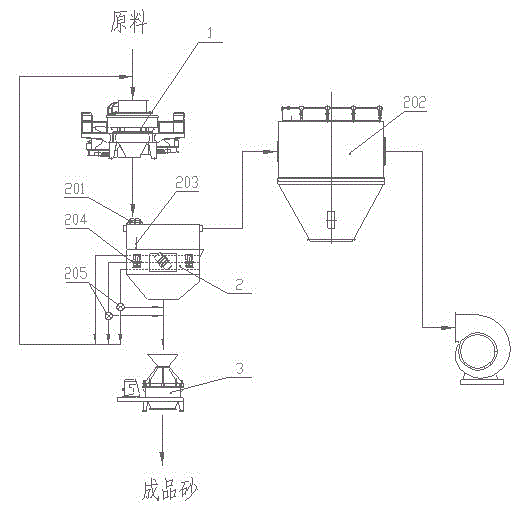

[0022] The present invention will be further described below in conjunction with the accompanying drawings.

[0023] see figure 1 , a high-quality machine-made sand production system, which includes a crusher 1, a grading controller 2, a particle type optimization machine 3, and conveying equipment. After the crushed stone is crushed by the crusher 1, it is transported to the grading controller 2 by the conveying equipment, and the machine-made sand is graded to finely control the grading of the machine-made sand, and the unqualified materials are returned to the crusher 1 for re-crushing; After the controller 2, a particle shape optimization machine 3 is added to optimize the particle shape of the machine-made sand.

[0024] The crusher 1 used in this embodiment is a vertical shaft impact crusher.

[0025] This embodiment adopts the grading controller 2, which includes an initial pre-division control room and a fine control room. The primary pre-separation control room inc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com