Process for treating waste liquid from catalytic cracking flue gas desulfurization

A technology for desulfurization waste liquid and treatment process, which is applied in gaseous effluent wastewater treatment, oxidized water/sewage treatment, sludge treatment, etc. problems, to achieve the effect of stable filtrate water quality, complete solid-liquid separation, and small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

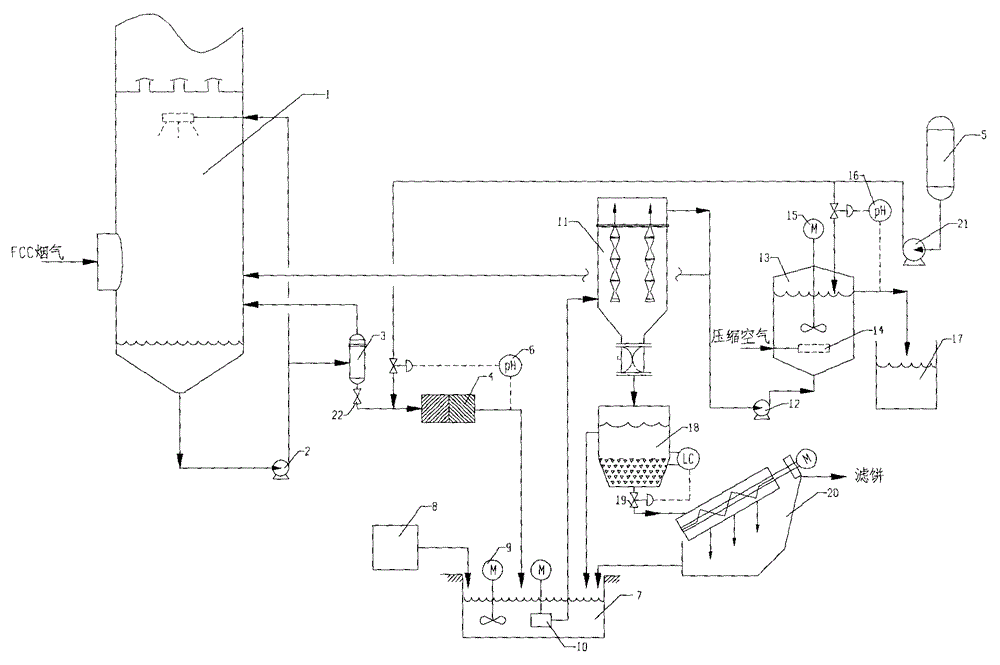

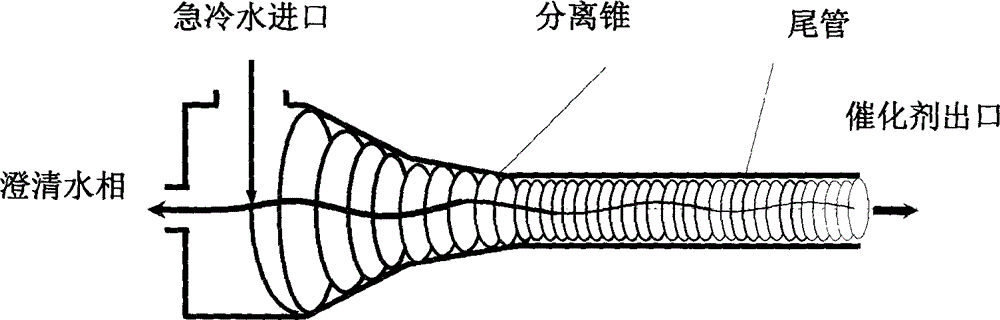

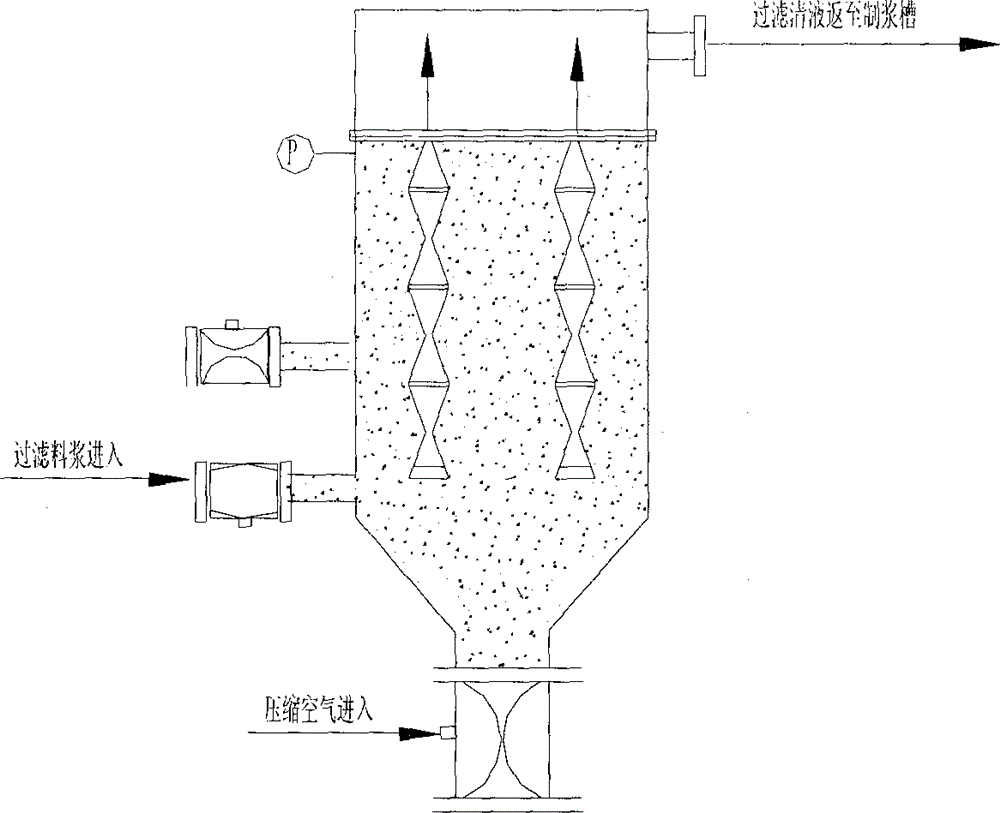

[0022] Below in conjunction with accompanying drawing, the present invention will be further described, as figure 1 As shown, the FCC flue gas enters the quenching scrubber 1 from the middle and lower part of the quenching scrubber 1 for quenching and saturation, forming an acidic waste liquid containing particulate matter, sulfate and sulfite. The waste liquid is discharged from the bottom of the tower, and most of it passes through the circulation pump. 2. Circulate back to the quenching washing tower 1, and the remaining part is sent to the hydrocyclone 3 for concentrated solid-liquid separation, and the catalyst dust is separated from the waste liquid, and the thin liquid produced by separation returns to the quenching washing at the top of the hydrocyclone 3 The tower 1 is circulated, and the concentrated liquid containing more particles produced by separation enters the neutralization reactor 4 through the bottom of the hydrocyclone 3 .

[0023] The concentrated liquid c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com