Manufacturing method for container with thermal insulation surface layer

A container and surface layer technology is applied in the field of the manufacturing method of a container with a heat-insulating surface layer, which can solve the problems of complexity, inability to bond, increase in cost, etc., achieve the best bonding strength, avoid leakage, and enhance the structural strength and durability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The following examples illustrate possible implementations of the present invention, but they are not intended to limit the protection scope of the present invention and are described in advance.

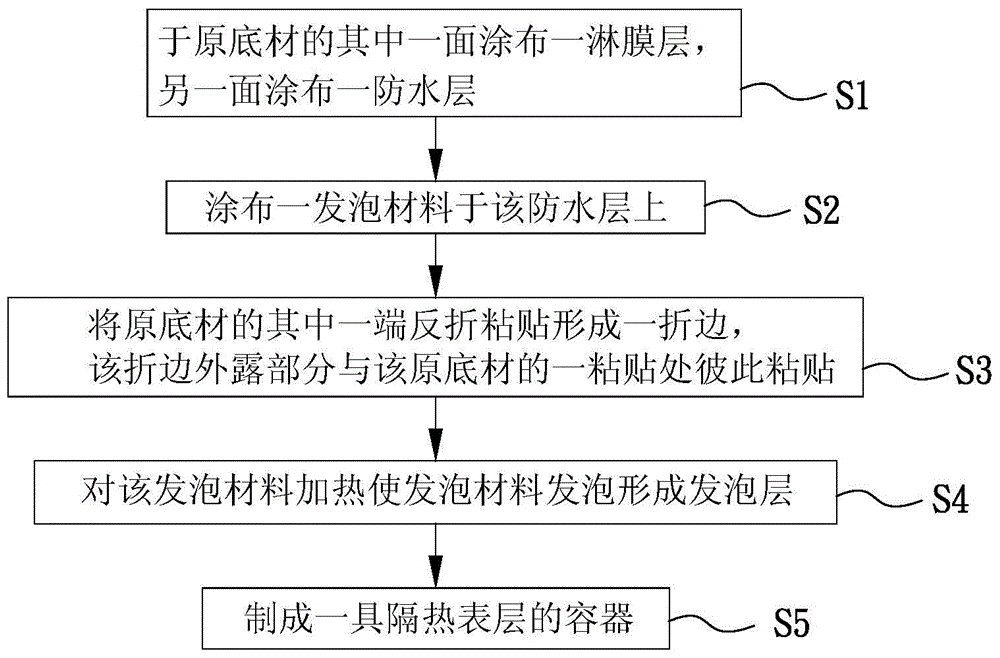

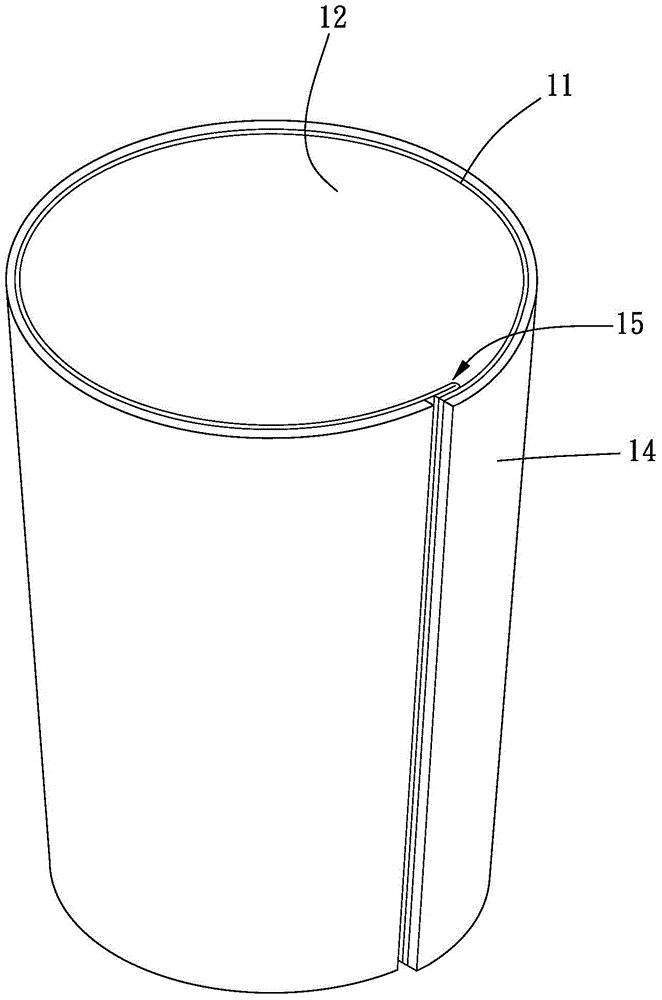

[0046] Please refer to Figure 1 to Figure 5 , the invention provides a method for preparing a container with a thermal insulation surface layer, comprising the following steps:

[0047] (1) S1: Prepare a paper or plastic original base material 11, the original base material 11 has a relative first surface and a second surface, and a coating layer 12 is coated on the first surface, the The coating layer 12 is selected from the group consisting of polypropylene and polyethylene terephthalate, and a waterproof layer 13 is coated on the second surface, and the waterproof layer 13 is composed of polyethylene;

[0048] (2) S2: Coating a foaming material on the waterproof layer 13 to cover at least part of the waterproof layer 13; wherein, the foaming material is formed by stirrin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com