Labeling device

A label sticking and material tape technology, which is applied in the field of automatic cutting, stripping, and labeling devices, can solve the problems of low work efficiency and high labor intensity, and achieve the effect of saving processing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

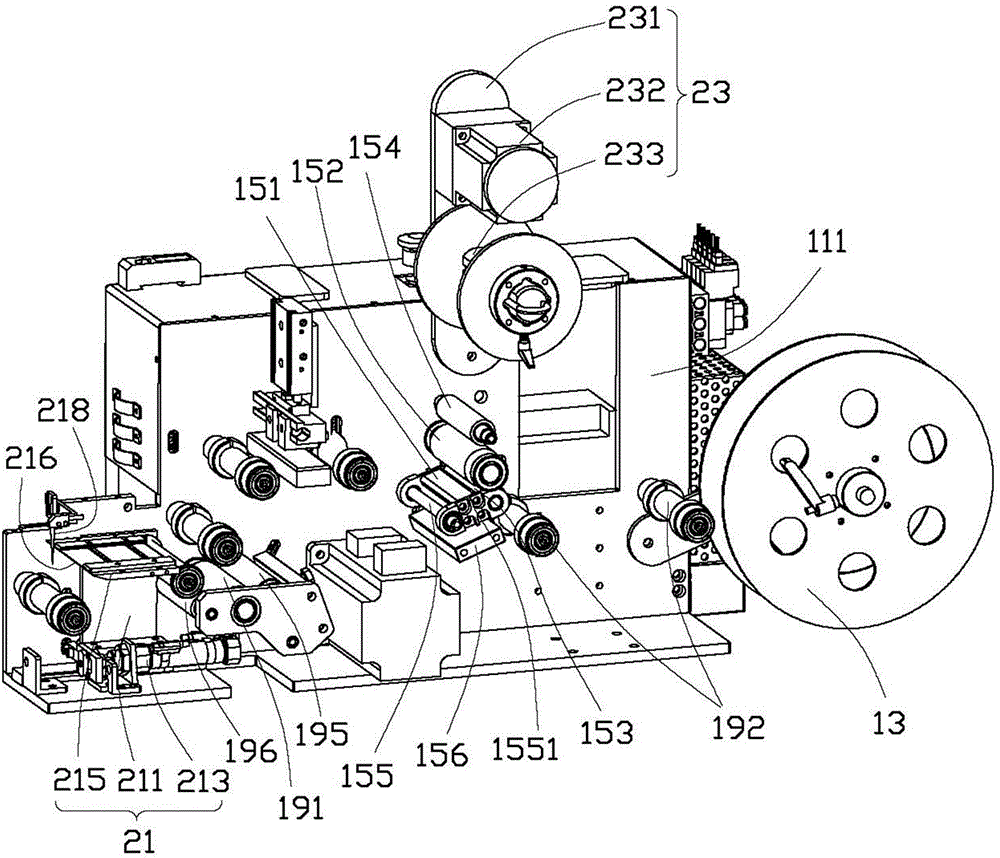

[0016] see figure 1 , the labeling device 100 of a preferred embodiment of the present invention includes a stripping mechanism (not shown in the figure), a punching mechanism 30 and a material transfer mechanism 50 . The punching mechanism 30 and the material transfer mechanism 50 are generally installed at two ends of the stripping mechanism 10 . The die-cutting mechanism 30 can die-cut the label tape (not shown) on the surface of a material tape 70 into labels with the same size, and collect the waste after cutting. The stripping mechanism is used for transporting the label strip and stripping the label off the strip 70 . The material transfer mechanism 50 can transport the label to the surface of a work piece (not shown) and make the label stick on the work piece. The label can also be foam. The workpiece can be made of metal or plastic.

[0017] see figure 2 , the stripping mechanism includes a support frame 11 , a reel 13 , a traction assembly 15 , a pressing assem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com