Stator punching structure of permanent magnet motor

A technology for stator punching and permanent magnet motors, which is applied in the direction of magnetic circuit shape/style/structure, synchronous motors with stationary armatures and rotating magnets, and static parts of magnetic circuits, which can solve the noise pollution of permanent magnet motors, The problems of high cost and reduced performance of permanent magnets can achieve the effects of low cost, convenient processing and reduced loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

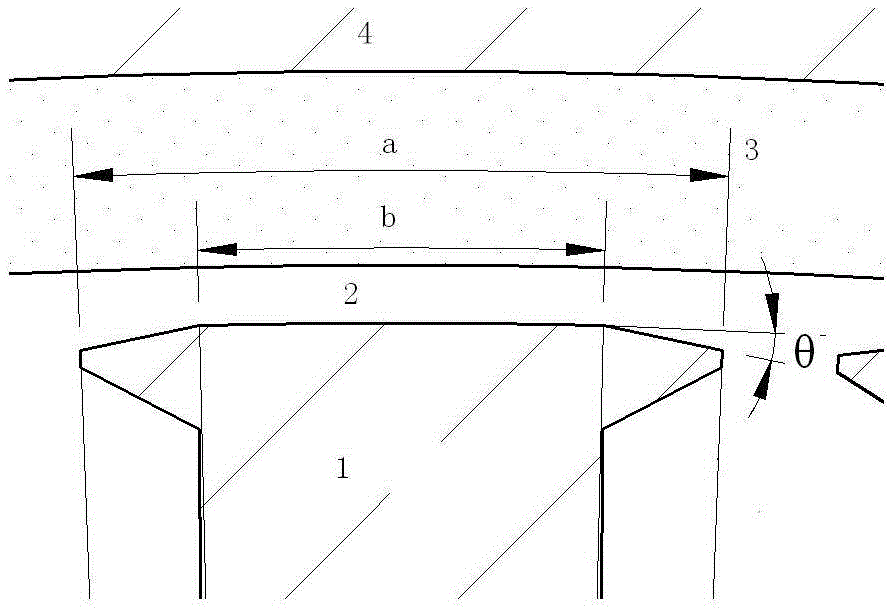

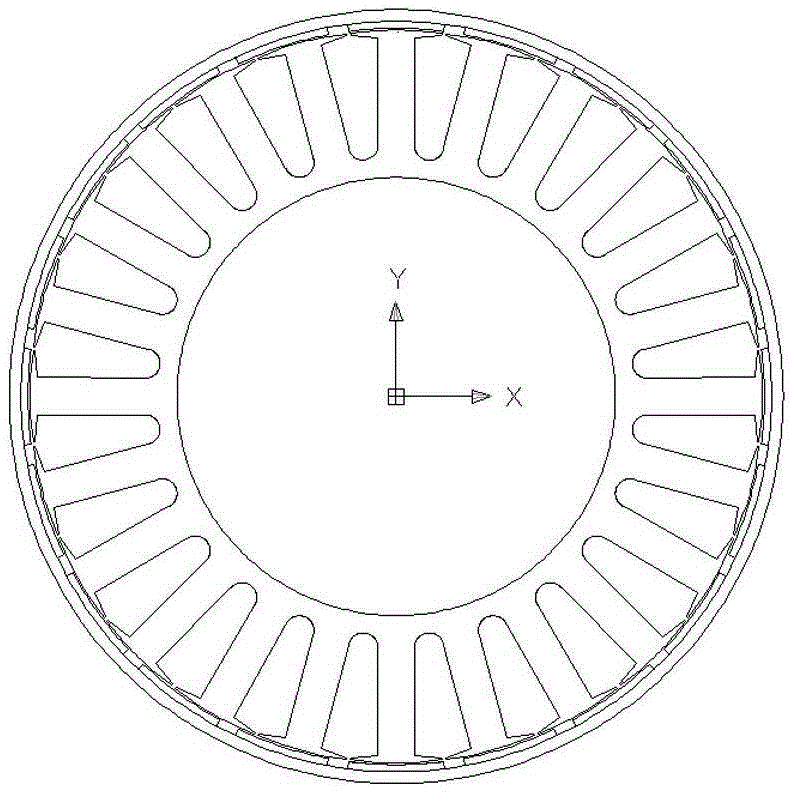

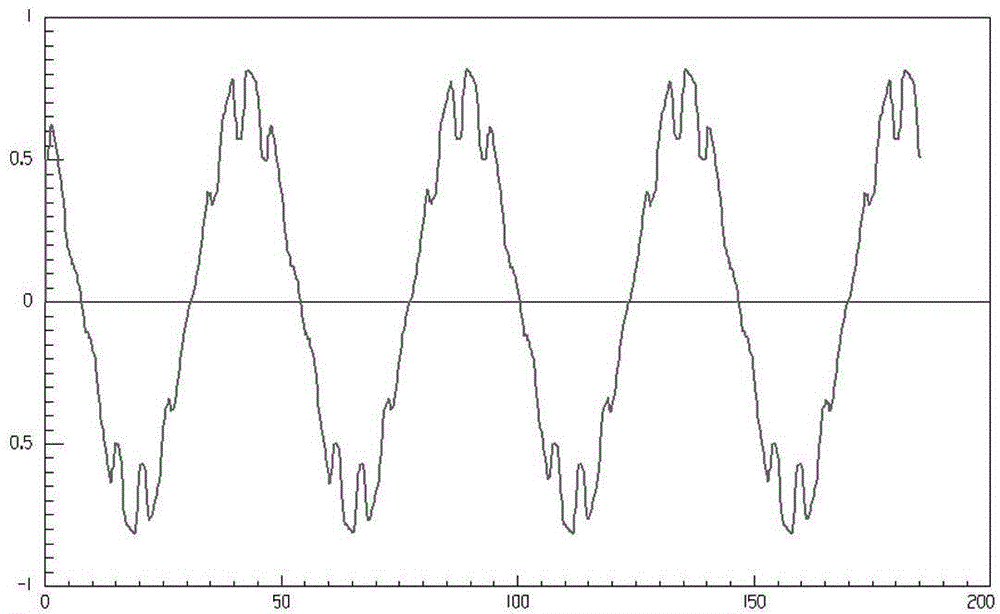

[0026] Where a is the angle occupied by each stator tooth, b is the angle occupied by the distance between the first two points of the tooth chamfer, θ The angle of chamfering for the stator teeth, when there is no chamfering, such as Figure 4 As shown, the distortion rate of the air-gap flux density waveform is 10.062%; when b / a is 0.5, and the chamfering angle θ is 10°, as Image 6 As shown, the air-gap magnetic density waveform distortion rate is 8.992%. It can be seen from the comparison that the harmonic content of the air gap magnetic density after chamfering is reduced, which reduces the loss of the motor, improves the efficiency, and reduces the influence of noise and torque fluctuation on the performance of the motor.

[0027] The working principle of the present invention is as follows:

[0028] By chamfering both ends of the stator teeth to establish unequal air gaps, reducing the harmonic content of the air gap magnetic field, reducing losses, improving motor e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com