Novel production device for generator corona-proof belt

A production device and anti-corona technology, which can be used in the configuration of equipment for processing textile materials, removal of liquid/gas/vapor with squeeze rollers, shape/style/structure of winding insulation, etc., which can solve the problems of high cost, unqualified products, Low efficiency and other problems, to achieve the effect of reducing production costs and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

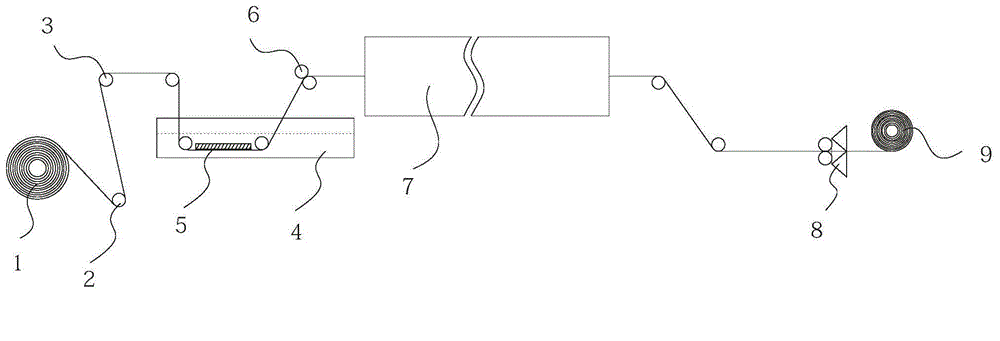

[0015] Such as figure 1 As shown, a new production device for anti-corona belts for generators includes a feeding device, a dipping tank 4, a rolling device 6, a drying box 7, a shearing device 8 and a winding device 9.

[0016] The feeding device includes a rolled gray cloth 1 and a power motor (not shown in the figure) for rotating and discharging the gray cloth 1; a lower shaft 2 and an upper shaft are respectively arranged below and above the discharging direction of the gray cloth 1 3. After the gray cloth 1 is pulled by the lower rotating shaft 2 and the upper rotating shaft 3, the texture and void distribution of the gray cloth 1 can be made more uniform, which is beneficial to the infiltration of the anti-corona paint impregnating liquid.

[0017] The gray cloth 1 turns to enter the dipping tank 4 after passing through the upper rotating shaft 3; a rolling device 6 for removing excess anti-corona paint impregnating liquid is arranged above the dipping tank 4, and the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com