Bearing capacity design method for prestressed concrete structure

A concrete structure and design method technology, applied in truss structures, calculations, special data processing applications, etc., can solve the problems that it is difficult to determine the influence of columns, walls, and tubes on the design and calculation results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

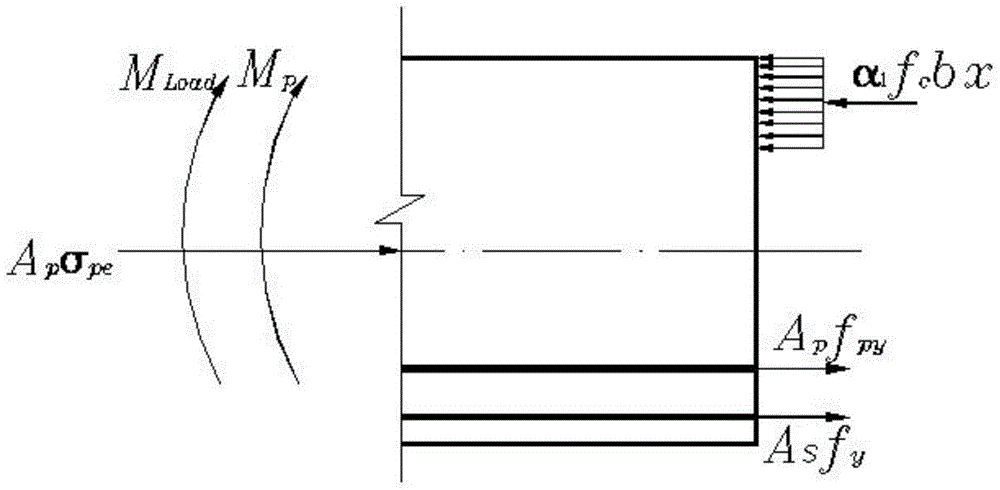

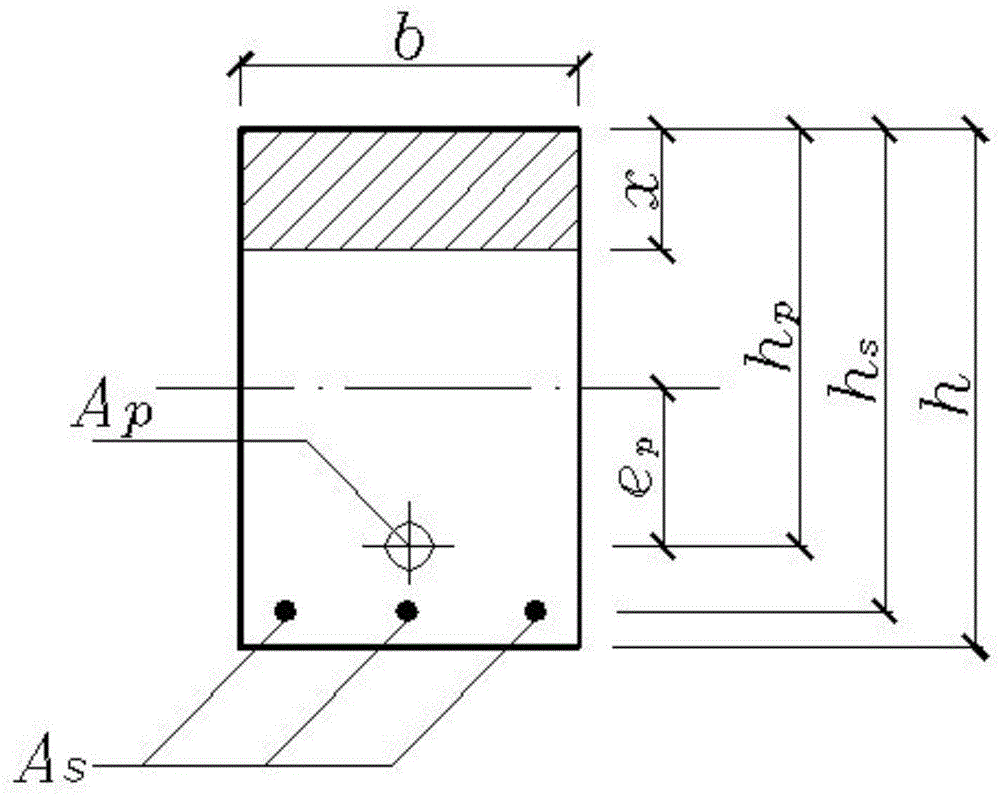

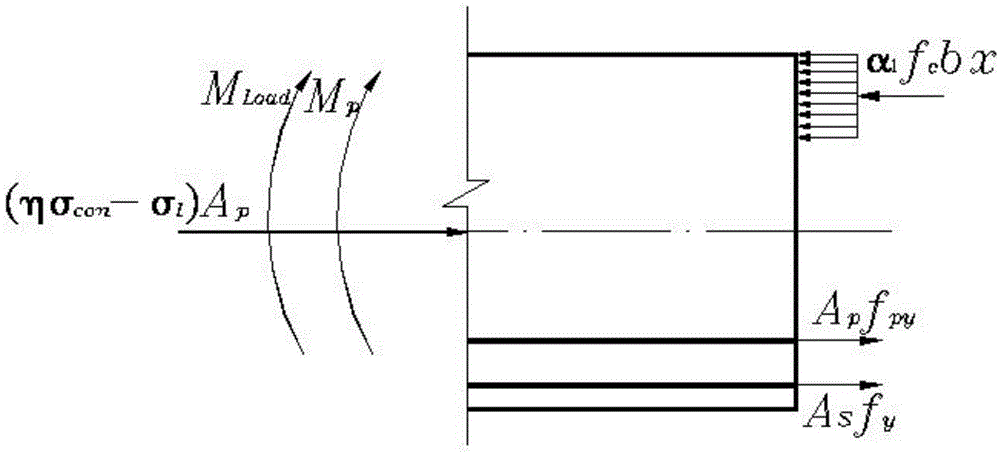

[0040] The bearing capacity design method of the prestressed concrete structure of the present embodiment, the bearing capacity design method of the prestressed concrete structure is realized through the following steps:

[0041] Step 1: Judging the concrete structure, if the concrete structure is determined to be a concrete structure with an infinite side structure, then perform steps 2 to 6, and if the concrete structure is determined to be a concrete structure with a limited side structure, then perform Calculations from Step 2 to Step 7;

[0042] Step 2: Calculate the cross-sectional area A of the longitudinal prestressed tendon in the tension zone p ;

[0043] Step 3: Determine the bending moment value M of the control section under the end preload caused by the tensioned prestressed tendon and the equivalent load in the span p , and determine the design value M of the external load and bending moment of the control section load , so as to calculate the sum of the bend...

specific Embodiment approach 2

[0069] The difference from Embodiment 1 is that in the method for designing the bearing capacity of prestressed concrete structures in this embodiment, the cross-sectional area A of the longitudinal prestressed tendons in the tension zone described in step 2 p The specific determination method:

[0070] First, determine the thickness of the prestressed tendon protective layer according to the construction code, and determine the line shape of the prestressed tendon according to the load type;

[0071] Then, the cross-sectional area A of the prestressed tendon is determined by calculating the crack governing equation p1 , and then calculate and determine the cross-sectional area A of the prestressed tendon through the deformation control equation p2 , take the cross-sectional area A of the prestressed tendon p1 and the cross-sectional area A of the prestressing tendons p2 The larger of the two is used as the cross-sectional area A of the prestressed tendon p .

specific Embodiment approach 3

[0072] The difference from the specific embodiment 1 or 2 is that in the design method of the bearing capacity of the prestressed concrete structure in this embodiment, the concrete structure of the limited side structure described in step 7 is a prestressed concrete frame structure, a prestressed concrete slab-column structure, Vertical member of prestressed concrete high-rise structure - one of column, shear wall and cylinder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com