Biogas fermentation process state control system and biogas fermentation process state control method thereof

A biogas fermentation and process state technology, applied in electrical program control, general control system, control/regulation system, etc., can solve the problem of poor consistency of product quality, difficult control of parameters such as temperature, pressure and pH value, and repeatable fermentation production process Sexual problems, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

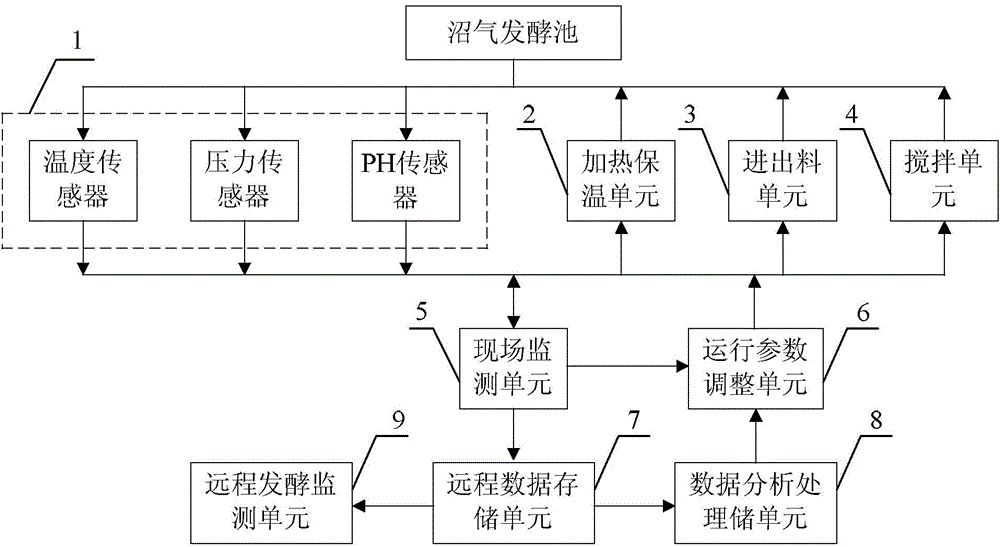

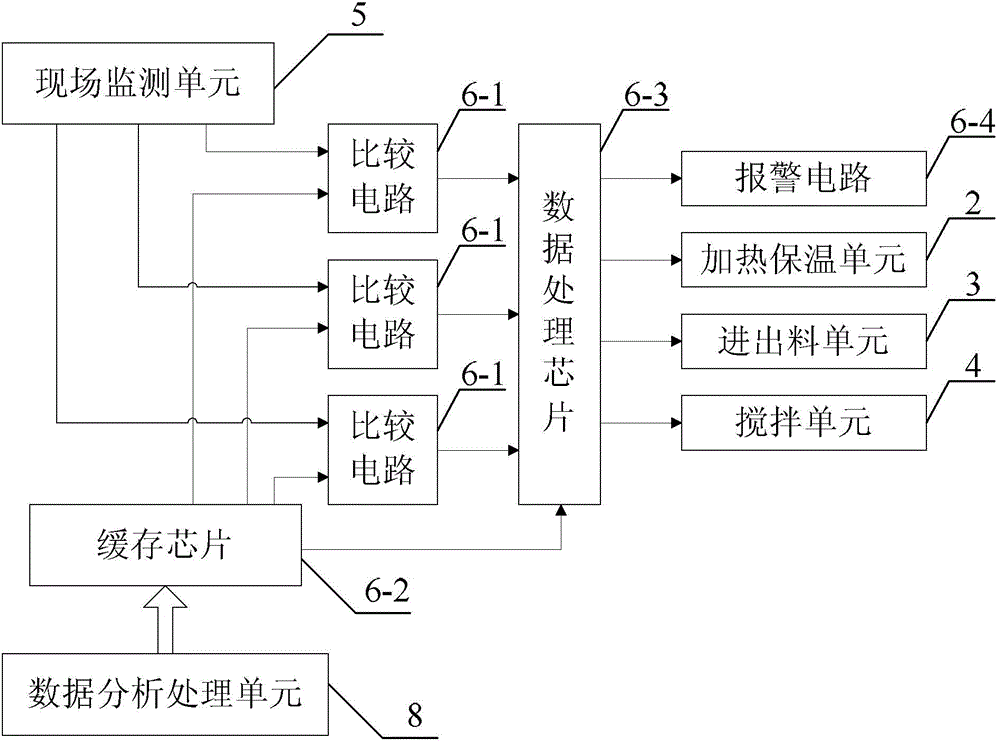

[0017] Specific implementation mode one: combine figure 1 To illustrate this embodiment, a biogas fermentation process state control system described in this embodiment includes a detection unit 1, an on-site monitoring unit 5 and an operating parameter adjustment unit 6;

[0018] The detection unit 1 includes a temperature sensor, a pressure sensor and a pH sensor;

[0019] The detection unit 1 sends the collected data to the on-site monitoring unit 5, and the on-site monitoring unit 5 sends the data to the operation parameter adjustment unit 6, and the operation parameter adjustment unit 6 is based on the data and the heating and heat preservation unit of the biogas fermentation tank 2. The extreme value of the operating parameters of the feeding and discharging unit 3 and the stirring unit 4 sends control signals to the heating and heat preservation unit 2, the feeding and discharging unit 3 and the stirring unit 4 respectively, and the heating and heat preservation unit 2,...

specific Embodiment approach 2

[0020] Specific implementation mode two: combination figure 1 Describe this embodiment, this embodiment is a further limitation of a biogas fermentation process state control system described in Embodiment 1, in this embodiment, the control system also includes a remote data storage unit 7 and a data analysis and processing unit 8;

[0021] The on-site monitoring unit 5 sends the data sent by the detection unit 1 to the remote data storage unit 7 by wired or wireless means, and the remote data storage unit 7 sends the data to the data analysis and processing unit 8, and the data analysis and processing unit 8 The received data is analyzed and calculated to obtain new operating parameter extreme values of the heating and heat preservation unit 2 , the feeding and discharging unit 3 and the stirring unit 4 , and the new operating parameter extreme values are sent to the operating parameter adjustment unit 6 .

[0022] In this embodiment, the data analysis and processing unit...

specific Embodiment approach 3

[0023] Specific implementation mode three: combination figure 1 Describe this embodiment. This embodiment is a further limitation of the biogas fermentation process state control system described in Embodiment 1. In this embodiment, the control system also includes a remote fermentation monitoring unit 9, a remote data storage unit 7. Send the data from the field monitoring unit 5 to the remote fermentation monitoring unit 9.

[0024] The remote fermentation monitoring unit 9 can be realized by computer. The remote fermentation monitoring unit 9 receives various data from the remote data storage unit 7 and stores these data for remote monitoring of the state of the biogas fermentation process.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com