Temperature measurement system and method for electrically heated glass

An electric heating glass and temperature measurement technology, which is applied in the field of automotive glass system and defogging, defrosting, temperature measurement of electric heating glass, can solve the problems affecting the appearance and optical performance of the car, and achieve the goal of improving safety and reducing costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

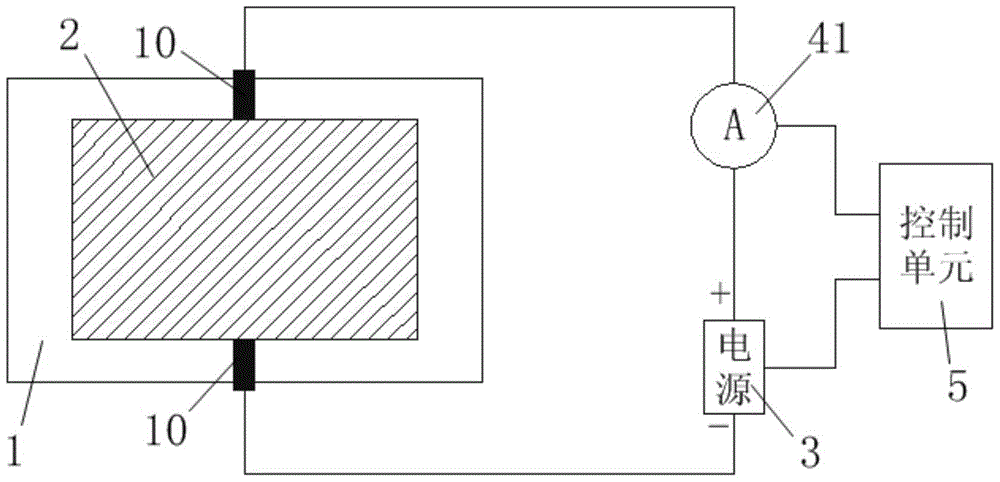

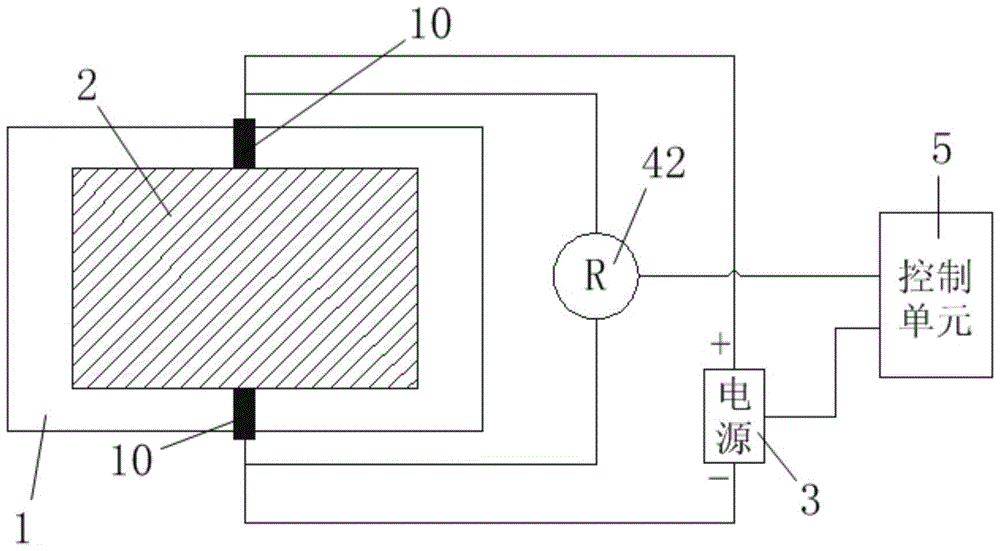

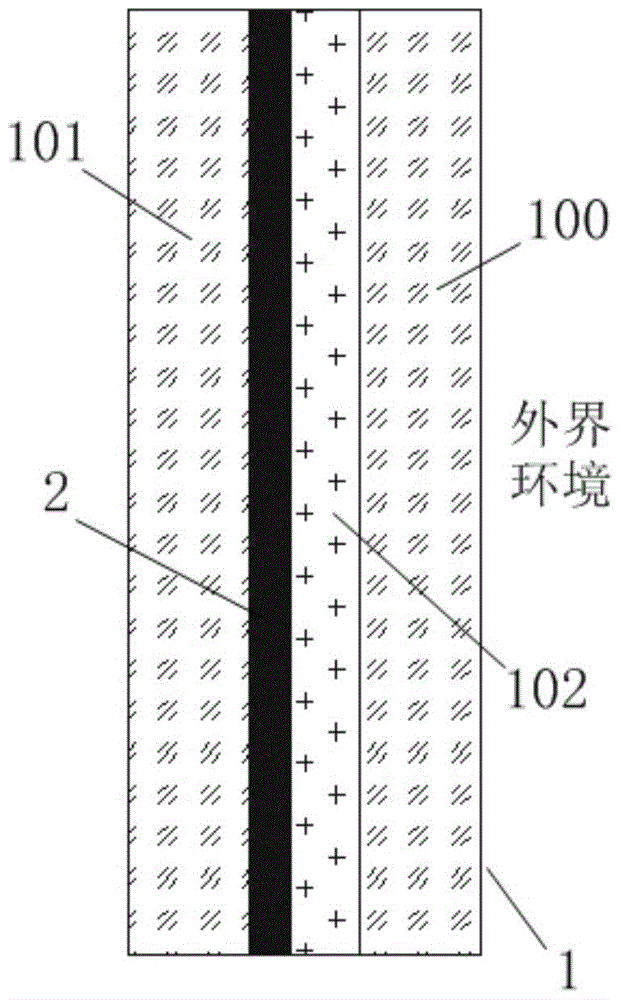

[0039] Such as figure 1 with figure 2 As shown, the temperature measurement system for electrically heated glass of the present invention includes a glass plate 1, an electric heating element 2 and a power supply 3, the electric heating element 2 is arranged on the surface of the glass plate 1, and the electric heating element 2 can be The glass plate 1 is heated by electrification and heating. The power supply 3 can apply a voltage U to both ends of the electric heating element 2. It is characterized in that it also includes a current measuring device or a resistance measuring device. The current measuring device or resistance measuring device can measure the electric heating element 2. Current I or resistance R after energization; In this way, the current or resistance of electric heating element 2 is directly measured by current measuring device or resistance measuring device being directly arranged in the energizing circuit formed by electric heating element 2 and power s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature coefficient of resistance | aaaaa | aaaaa |

| temperature coefficient of resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com