Squeeze roll for sizing machine

A squeeze roller and pulper technology, applied in the field of squeeze rollers, can solve the problems affecting the strengthening of sizing yarn, maintaining straightness and wear resistance, increasing side yarn breakage, increasing sizing yarn elongation, etc., so as to improve the quality of sizing , increase the coefficient of friction, reduce the effect of bearing force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention is described below in conjunction with accompanying drawing.

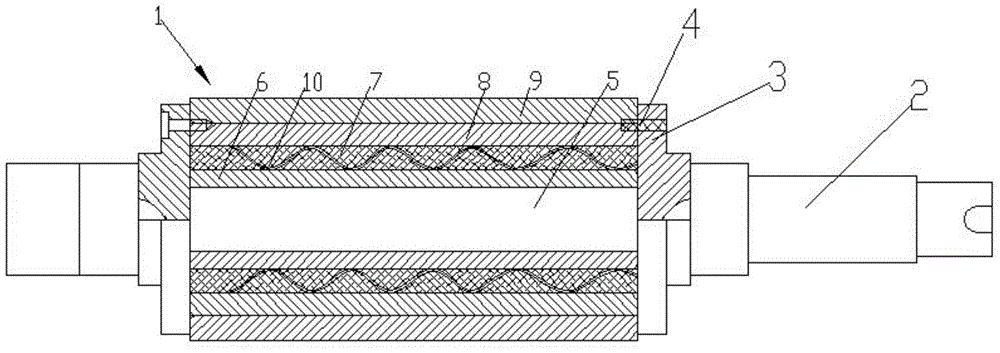

[0011] A squeeze roll for a sizing machine according to the present invention is mainly composed of a roll body 1 and a detachable two-end shaft structure 2 arranged at both ends of the roll body 1; the roll body 1 is a hollow structure, The shaft structures at both ends are respectively inserted on the end surface of the roller body 1, and then the chuck 3 at the end of the end shaft structure is locked on the end surface of the roller body 1 through the fastener 4; the roller body 1 includes a metal roller core 5 and a rubber layer, the rubber layer is mainly composed of a bottom rubber layer 6, a slow rubber layer 7, a surface buffer layer and a surface layer 9, and the inside of the slow rubber layer 7 is provided with a gap layer 10; the gap layer 10 It is in the shape of a wavy hole, and the gap layer extends inward from one end of the slow rubber layer 7, and the gap layer is a b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com