Method for leaching ore concentrate from copper oxide ores based on complexing reaction, and its leaching agent

A technology of copper oxide ore complexation reaction, applied in the field of mineral metallurgy, can solve the problems of undiscovered high-efficiency copper leaching technology solutions, and achieve the effect of simple operation and low process cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

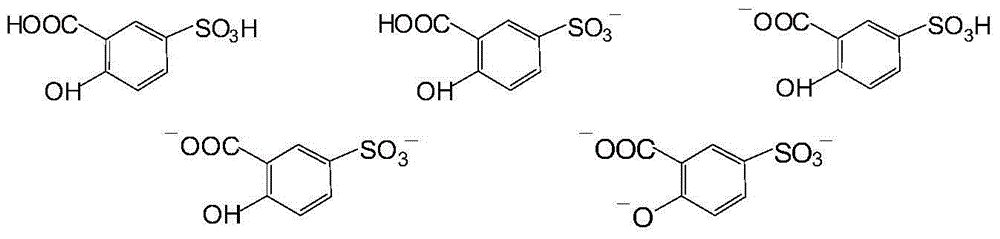

Image

Examples

Embodiment 1

[0033] An embodiment of the present invention provides a leaching agent for a complex reaction with copper oxide ore concentrate with a copper grade of 25%. The leaching agent is prepared by uniformly mixing 5-sulfosalicylic acid and water. The concentration of the solution containing 5-sulfosalicylic acid in the leaching agent is 0.05mol / L. The leaching rate of copper is about 85.5% under the conditions of temperature 30°C, ore particle size less than 74 μm accounted for 80% by weight, leaching agent solution and copper oxide concentrate powder mass liquid-solid ratio of 20:1.

Embodiment 2

[0035] The embodiment of the present invention provides a leaching agent for complex reaction with copper oxide ore concentrate with a copper grade of 25%. The leaching agent is mainly prepared by uniformly mixing 5-sulfosalicylic acid and water. The concentration of the solution containing 5-sulfosalicylic acid in the leaching agent is 0.10mol / L. Under the conditions of temperature 30°C, ore particle size less than 74μm accounted for 80% by weight, leaching agent solution and copper oxide concentrate powder mass liquid-solid ratio of 20:1, the copper leaching rate is about 94.2%.

Embodiment 3

[0037] The embodiment of the present invention provides a leaching agent for complex reaction with copper oxide ore concentrate with a copper grade of 25%. The leaching agent is mainly prepared by uniformly mixing 5-sulfosalicylic acid and water. The concentration of the solution containing 5-sulfosalicylic acid in the leaching agent is 0.20mol / L. The leaching rate of copper is about 96.8% under the conditions of temperature 30°C, ore particle size less than 74 μm accounted for 80% by weight, leaching agent solution and copper oxide concentrate powder mass liquid-solid ratio of 20:1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com