Folium mori polysaccharide as well as separation and purification preparation method and application thereof

A mulberry leaf polysaccharide, separation and purification technology, which is applied to medical preparations, pharmaceutical formulations, organic active ingredients and other directions containing active ingredients, can solve the problems of no reports on the fractionation, separation and purification of mulberry leaf polysaccharides and research on properties, and achieve good anti-microbial properties. Coagulation function, low energy consumption, simple and feasible effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

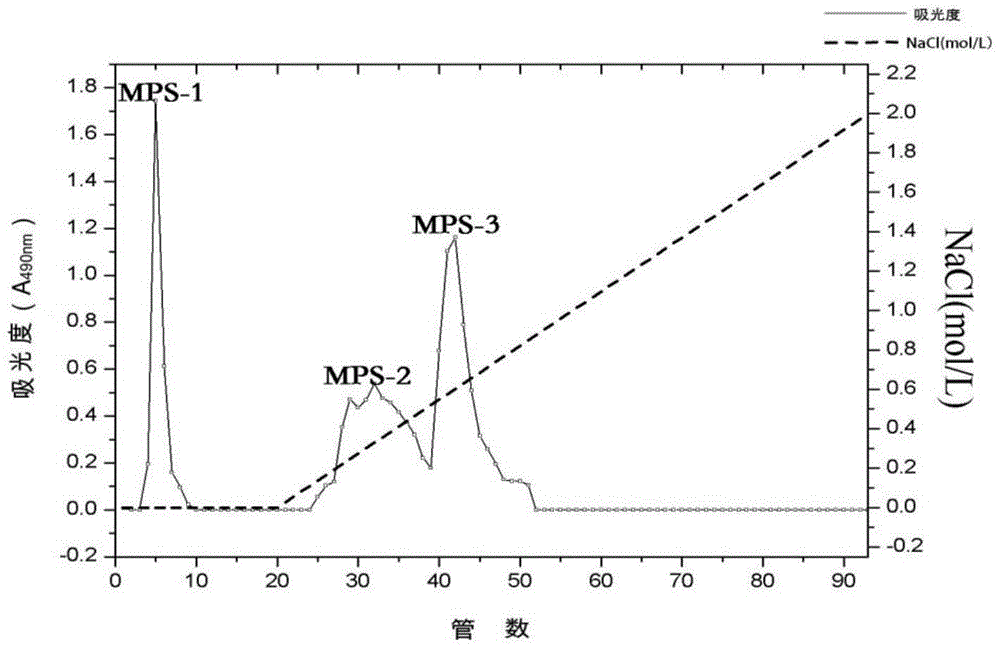

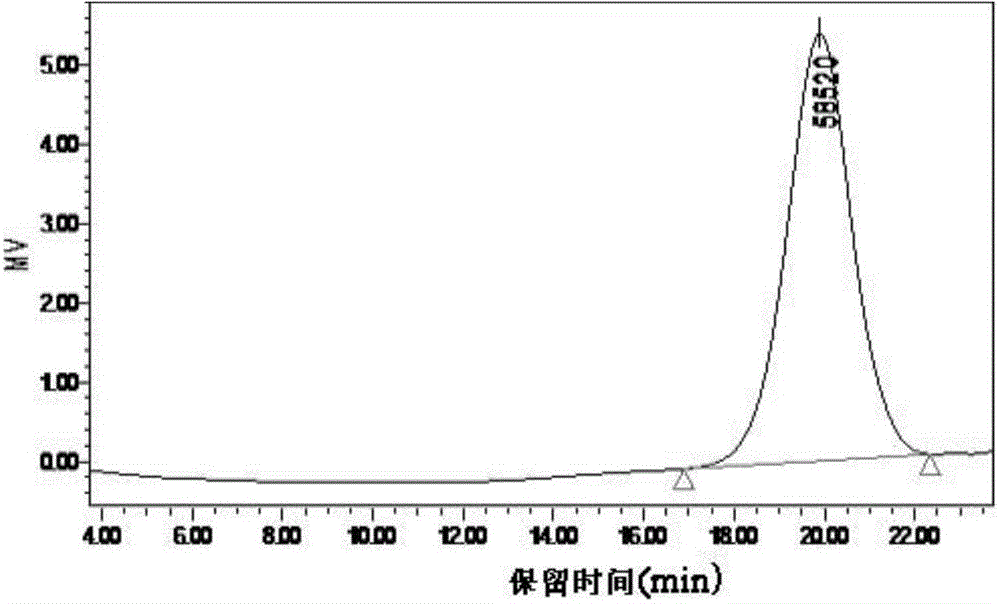

[0052] After the mulberry leaves are pulverized by a pulverizer, pass through a 100-mesh sieve to obtain the mulberry leaf coarse powder, extract the mulberry leaf coarse powder and distilled water at a weight ratio of 1:10 at 60°C for 90 minutes, remove impurities to obtain the filtrate A, and concentrate the filtrate A to 1 / 5 of the original volume, then slowly add 4 times the volume of absolute ethanol of the concentrated filtrate A until the volume concentration of ethanol reaches 80%, centrifuge to remove the supernatant after alcohol precipitation for 12 hours, and vacuum freeze-dry to obtain the crude polysaccharide of mulberry leaves a.

[0053] Dissolve the prepared mulberry leaf crude polysaccharide A in distilled water, centrifuge for 10 minutes at a speed of 4000r / min, and then put it on a polyamide column, use distilled water as the mobile phase, and the flow rate is 1.0mL / min, collect the polysaccharide solution, and collect the polysaccharide The pH of the solut...

Embodiment 2

[0057] After the mulberry leaves are pulverized by a pulverizer, pass through a 60-mesh sieve to obtain the mulberry leaf coarse powder, extract the mulberry leaf coarse powder and distilled water at a weight ratio of 1:40 at 90°C for 150 minutes, remove impurities to obtain the filtrate A, and concentrate the filtrate A to 1 / 5 of the original volume, then slowly add 4 times the volume of dehydrated ethanol of the concentrated filtrate A until the volume concentration of ethanol reaches 80%, centrifuge to remove the supernatant after alcohol precipitation for 24 hours, and vacuum freeze-dry to obtain the crude polysaccharide of mulberry leaves a.

[0058] Dissolve the prepared mulberry leaf crude polysaccharide A in distilled water, centrifuge for 20min at a speed of 3600r / min, and then put it on a polyamide column, use distilled water as the mobile phase, and the flow rate is 2.0ml / min, collect the polysaccharide solution, and collect the polysaccharide The pH of the solution...

Embodiment 3

[0061] Embodiment 3 anticoagulant health product—preparation of mulberry leaf drink:

[0062] In parts by weight, the ratio of water to coarse mulberry leaves is 1-20:100, the extraction temperature is 75-95°C, and the time is 5-30 minutes. After leaching, use 250-mesh nylon cloth to filter and remove residue, and quickly cool to 5°C. , placed for 24h to clarify, 0.5μm fine filtration to obtain clarified mulberry leaf juice. 0.04-0.2% MPS-2b, 3-6% sucrose, 0.03-0.07% ascorbic acid and other known excipients are firstly dissolved in some warm water and filtered. Mix it with the finely filtered mulberry leaf juice, sterilize at 135° C. for 5-7 seconds, and bottle it to obtain an anticoagulant health-care mulberry leaf drink.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com