Anti-compression shockproof aerated concrete building block and preparation method thereof

A technology of aerated concrete and blocks, applied in ceramic products, other household appliances, applications, etc., can solve the problems of general compression and shock resistance, poor performance and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0017] The invention provides a method for preparing a compression-resistant and anti-shock aerated concrete block, wherein the preparation method includes:

[0018] (1) mixing lime, aluminum powder and water to obtain a mixture M1;

[0019] (2) Add early strength agent to mixture M1 to obtain mixture M2;

[0020] (3) Add cement, fly ash and foam stabilizer to the mixture M2 to obtain the mixture M3;

[0021] (4) Carry out initial maintenance after pouring the mixture M3 into the mold;

[0022] (5) After the initial maintenance is finished, demould and divide to obtain the block embryo body;

[0023] (6) Carry out steam curing to the block embryo body to obtain an aerated concrete block; wherein,

[0024] Relative to 100 parts by weight of the cement, the amount of the lime used is 50-200 parts by weight, the amount of the fly ash is 300-800 parts by weight, the amount of the water is 80-500 parts by weight, the The amount of the aluminum powder is 0.1-5 parts by weight, t...

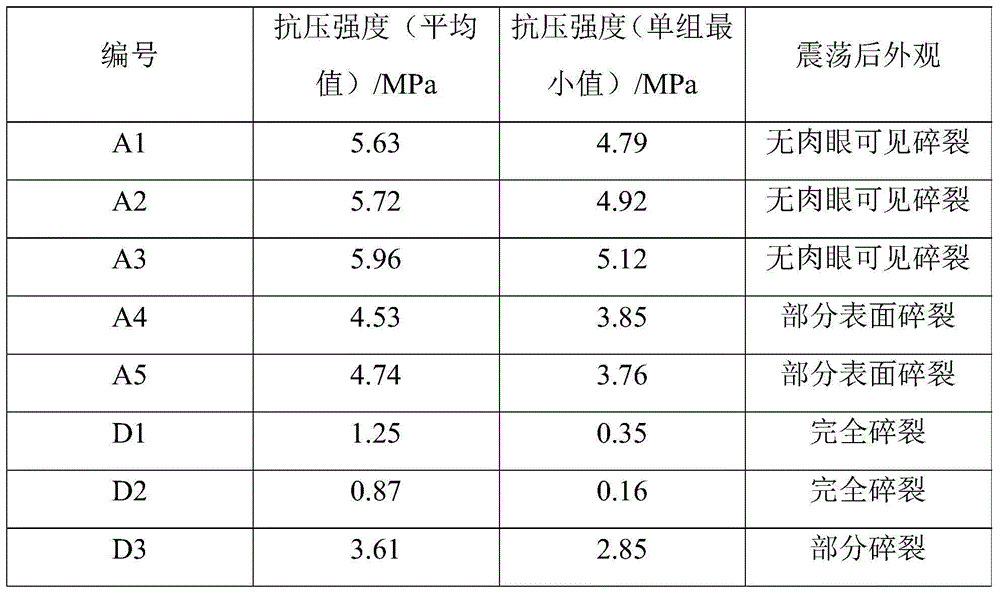

Embodiment 1

[0039] Mix 80g of lime, 0.5g of aluminum powder and 150g of water to obtain mixture M1; add 2g of sodium chloride to mixture M1 to obtain mixture M2; add 5g of gypsum, 100g of cement, and 400g of fly ash to mixture M2 and 50g of foam stabilizer to obtain the mixture M3; pour the mixture M3 into the mold and place it in an environment with a temperature of 40°C for 1 hour of initial curing; after the initial curing is completed, demould and split at a cutting speed of 70mm / s , to obtain the block embryo body; vacuumize the block embryo body to a pressure of 0.07MPa, and keep it for 0.5h; then increase the pressure at a constant speed for 1.5h to a pressure of 1.2MPa, and keep the constant pressure for 6h; then reduce the pressure for 1.5h to 0.1 MPa, the compression-resistant and shock-proof aerated concrete block A1 was prepared.

Embodiment 2

[0041] Mix 150g of lime, 2g of aluminum powder and 300g of water to obtain mixture M1; add 5g of sodium chloride to mixture M1 to obtain mixture M2; add 50g of gypsum, 100g of cement, 700g of fly ash and 150g of foam stabilizer to obtain the mixture M3; pour the mixture M3 into the mold and place it in an environment with a temperature of 65°C for 3.5 hours of initial curing; after the initial curing is completed, demould and split at a splitting speed of 100mm / s , to obtain the block embryo body; after vacuumizing the block embryo body to a pressure of 0.07MPa, keep it for 1h; then increase the pressure at a constant speed for 2h to a pressure of 1.2MPa, then keep the constant pressure for 10h; then reduce the pressure for 2h to 0.1MPa, and make Obtain the anti-shock aerated concrete block A2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com