High-stable fire-retardant screen

A high-stability, fire-resistant technology, applied in fire prevention, building components, etc., can solve the problems of enterprise production safety hazards, wall collapse, collapse, etc., to reduce safety hazards, easy installation and connection, good compression and shock resistance performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

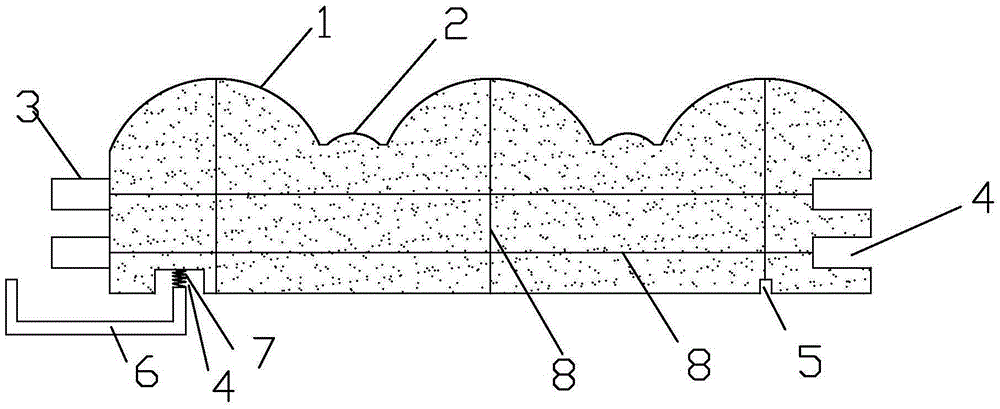

[0013] Such as figure 1 As shown, a high-stability fire barrier, the upper surface of the fire barrier body has large arc-shaped protrusions 1 and small arc-shaped protrusions 2 distributed at intervals; between every two adjacent protrusions The joint of the fire screen is set as a plane; one end of the fire screen is provided with two protrusions 3, the protrusions 3 are in the shape of a cuboid, and the other end is provided with a groove 4 adapted to the protrusions 3; the fire screen One side of the lower surface of the fire screen is also provided with a groove 4, and a spring 7 is connected to one end of a U-shaped frame 6 in the groove 4; the other side of the lower surface of the fire screen is provided with a concave hole 5, and the concave hole 5 It is adapted to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com